| اسم | حقن الريشات | |

| مادة | الفولاذ المقاوم للصدأ 304 ، الفولاذ المقاوم للصدأ 316 ، DSS F51 ، الكربون الصلب A105N ، وكذلك Inconel 625 | |

| درجة حرارة التشغيل | -20±120 | |

| ميزة | أولا ، سهولة التشغيل | |

| ثانيا ، دقة عالية حياة طويلة | ||

| أخيرا ، كفاءة عالية ، تكلفة منخفضة | ||

| قسط | ترينيداد وتوباغو/LC | |

| ميزة | أولا ، فهي خفيفة الوزن ومرنة. | |

| ثانيا ، كفاءة حقن ممتازة. | ||

| أخيرا ، تتبع دقيق للموقع. |

| نموذج | ||||||||||||||||||||||||||||

سي | ريشة حاقن كيميائي | |||||||||||||||||||||||||||

| شفرة | سدادة | |||||||||||||||||||||||||||

| بكسكسكس | يكتب | مادة | مادة مانعة للتسرب | |||||||||||||||||||||||||

| 0 | لا يوجد طلب | 0 | CS | 0 | لا يوجد طلب | |||||||||||||||||||||||

| 1 | هيئة المكونات جوفاء | 1 | 316SS | 3 | مفاجآت صيف دبي | 1 | فيتون O-الدائري / PTFE التعبئة الأولية | |||||||||||||||||||||

| 2 | جسم التوصيل الصلب | 2 | 316LSS | 4 | إنكونيل | 2 | هنبر | |||||||||||||||||||||

| شفرة | حقن الجوز | |||||||||||||||||||||||||||

| نكس | حجم الاتصال | مادة | ||||||||||||||||||||||||||

| 0 | أي لا يوجد طلب | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | أي 1/4 " | 1 | أي 316SS | 3 | أي مفاجآت صيف دبي | |||||||||||||||||||||||

| 2 | أي 1/2 " | 2 | أي 316LSS | 4 | أي إنكونيل | |||||||||||||||||||||||

| –رمز | أنبوب الحقن | |||||||||||||||||||||||||||

| Sxxx-Lx" | حجم الاتصال | مادة | فوهه | حجم الخط (x") | ||||||||||||||||||||||||

| 0 | لا يوجد طلب | 0 | CS | 0 | أي لا يوجد طلب | يكون الوضع الأكثر فعالية للحقن بشكل عام في وسط الأنبوب | ||||||||||||||||||||||

| 1 | أي 1/4 " | 1 | أي 316SS | 1 | أي مفتوح | |||||||||||||||||||||||

| 2 | أي 1/2 " | 2 | أي 316LSS | 2 | أي ريشة | |||||||||||||||||||||||

| 3 | أي مفاجآت صيف دبي | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | أي إنكونيل | |||||||||||||||||||||||||||

| –رمز | Nipple and Valve(or end Flange)of Tee | |||||||||||||||||||||||||||

| تكس | حجم الاتصال | مادة | ||||||||||||||||||||||||||

| 0 | أي لا يوجد طلب | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | أي 1/4 "الحلمة | a | أي 1/4 "الحلمة والصمام | 1 | أي 316SS | |||||||||||||||||||||||

| 2 | أي 1/2 "الحلمة | b | أي 1/2 "الحلمة والصمام | 2 | أي 316LSS | |||||||||||||||||||||||

| 3 | أي 3/4 "الحلمة | c | أي 3/4 "الحلمة والصمام | 3 | أي D SS | |||||||||||||||||||||||

| 4 | أي 1 "الحلمة | d | أي 1 "الحلمة والصمام | 4 | أي إنكونيل | |||||||||||||||||||||||

| 5 | أي 1/4 "شفة | e | أي 1/4 "شفة نهاية الحلمة | |||||||||||||||||||||||||

| 6 | أي 1/2 "شفة | f | أي 1/2 "شفة نهاية الحلمة | |||||||||||||||||||||||||

| 7 | أي 3/4 "شفة | g | أي 3/4 "شفة نهاية الحلمة | |||||||||||||||||||||||||

| 8 | أي 1 "شفة | ح | أي 1 "شفة نهاية الحلمة | |||||||||||||||||||||||||

| على سبيل المثال ، SI-P221-N12-S122-L4 "-T22 SI:e.g. Sampling & Injection Assembly, P221: على سبيل المثال جسم المكونات الصلبة في 316LSS Viton O-Ring والتعبئة الأولية PTFE ، N12:e. g. injection Nut Connection Size is 1/4″and المواد هي 316LSS ، S122:e. g. injection أنبوب حجم الاتصال هو 1/4 "و المواد هي 316LSS. نوع الفوهة هو الريشات L4 ": ل 4" الأنابيب. تي 22: حلمة من حجم اتصال نقطة الإنطلاق هو 1/2 "، مادة الحلمة هي 316LSS | ||||||||||||||||||||||||||||

1. Introduction to Injection Quills

حقن الريشات serve a crucial role across various industries, providing a controlled method for introducing treatment chemicals into pressurized process streams. These precision devices are indispensable in sectors such as oil and gas, chemical processing, and water treatment, where maintaining the integrity and efficiency of the flow systems is paramount.

2. Purpose of Injection Quills in Industry

The primary purpose of Injection Quills is to inject chemicals directly into a pipeline or vessel to prevent issues such as corrosion, scaling, or biological growth. By doing so, they protect the system from damage, improve product quality, and ensure compliance with environmental standards. Industries rely on these quills for their precision and effectiveness in chemical dispersion, which is critical for the longevity and reliability of their operations.

3. Common Applications in Oil and Gas, Chemical Processing, and Water Treatment

In the oil and gas sector, Injection Quills are vital for introducing corrosion inhibitors to safeguard pipeline infrastructure. Chemical processing facilities utilize them to dose reactants or catalysts precisely, optimizing reaction outcomes. In water treatment, quills play a central role in disinfecting and conditioning the water, ensuring that it meets both safety and quality guidelines.

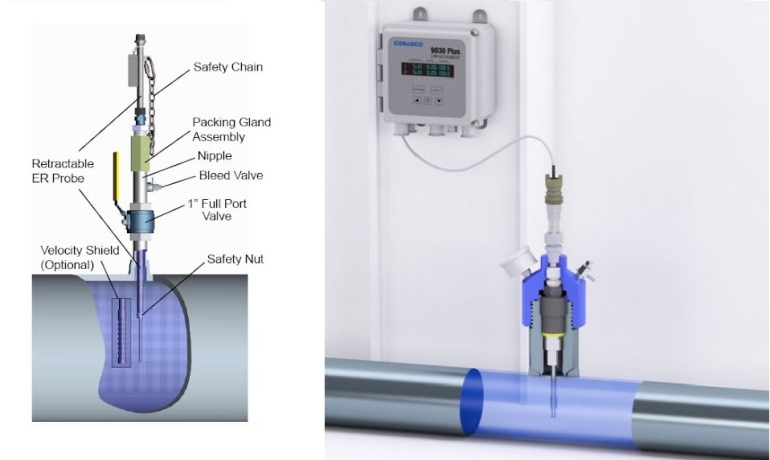

4.Design and Functionality

Injection Quills are expertly designed to introduce chemicals into pressurized streams with remarkable precision. They feature a slender insertion point that extends into the central flow path of the pipeline, ensuring that chemicals are evenly mixed into the process fluid. So this central placement is key to the effective dispersion of treatment agents and helps to prevent the chemicals from settling on the pipe walls, where they could create concentrated areas that might lead to corrosion or other integrity issues.

5. Importance of Central Placement for Effective Chemical Mixing

The strategic central placement of Injection Quills is critical for achieving optimal mixing and dilution of chemicals within the process stream. By positioning the quill correctly, it ensures that the injected chemicals are rapidly integrated into the high-velocity flow, promoting uniform distribution and immediate interaction with the process fluid.

6. Prevention of Chemical Adherence to Pipeline Walls

The design of Injection Quills actively prevents the chemicals from adhering to the pipeline walls, which is a common challenge with direct injections. This not only maintains the quality and effectiveness of the chemical treatment but also protects the pipeline material from potential damage due to high concentrations of chemicals at any given point. As a result, Injection Quills are a fundamental component in maintaining the smooth and safe operation of industrial pipelines and vessels.

7. Key Features of Injection Quills

Targeted Chemical Delivery

Firstly, Injection Quills excel in delivering chemicals with precision, ensuring they enter the process stream at the most effective location. This targeted approach maximizes the effectiveness of the chemical treatment, optimizing process outcomes and promoting system efficiency.

Material Construction

Then, crafted from materials resistant to a broad spectrum of chemicals and operating conditions, Injection Quills withstand the rigors of industrial environments. This resilience ensures compatibility with different chemicals, providing a versatile solution across various sectors without compromising on durability.

Customization Capabilities

At last, recognizing the unique demands of each process, Injection Quills offer extensive customization options. They can be tailored in length and equipped with a variety of nozzle types to meet the specific needs of the process, ensuring an optimal fit and performance.

8. Safety and Efficiency Enhancements

Integrated Check Valve

Each Injection Quill incorporates a check valve, a critical feature that actively prevents the backflow of process fluid. This valve plays a vital role in maintaining the chemical integrity, ensuring accurate dosing and enhancing the overall safety of the chemical injection system.

Installation Advantages

Because they are designed with a focus on ease of integration, Injection Quills facilitate a straightforward installation process. So this minimally invasive design allows for quick incorporation into existing systems, minimizing disruption and downtime, thereby maintaining continual process

9. Industrial Applications

Use Cases

Because Injection Quills are instrumental in a variety of industrial applications. So they are paramount in the delivery of corrosion inhibitors, ensuring the longevity of pipelines by mitigating corrosive processes. In biocide delivery, quills ensure the precise dosage necessary to prevent biological growth, which can compromise the integrity of fluid systems. Additionally, they play a crucial role in pH adjustment, neutralizing acidic or alkaline waters to prevent damage to equipment and ensure compliance with environmental discharge regulations.

Impact on System Integrity

Injection Quills are guardians of system integrity, actively contributing to the preservation and efficiency of industrial processes. By ensuring that chemicals are accurately and evenly introduced into the system, quills prevent localized concentrations that can lead to equipment wear or failure. Their use ensures that chemical treatments are more effective, thus extending the lifespan of assets and maintaining consistent process performance.

خاتمة

In summary, Injection Quills are vital components in the realm of industrial chemical processes. Then their capacity to deliver treatment chemicals in a controlled and precise manner makes them indispensable for maintaining the integrity and efficiency of industrial operations. The strategic application of Injection Quills significantly contributes to operational excellence, positioning them as critical tools for any process that involves chemical treatment. So their role in ensuring the longevity and peak performance of industrial systems cannot be overstated.

10. Our Service

1. Firstly, there are many kinds of chemical injection access fitting with different type to meet difference requirements.

2. Secondly, samples will be offered to attest to the quality and our services.

3. And then the fastest feedback!

4. After that, the fastest delivery time.

5. At last, 24 hours,7 days online.

11. Introduction of EMT

معهد شنيانغ لتطوير تكنولوجيا المصادر وشنيانغ EMT الأنابيب والتكنولوجيا المحدودة هي متخصصة في تصنيع المنتجات لرصد التآكل وتنظيف خطوط الأنابيب. منذ تأسيسنا في عام 1993 ، نقوم بتقديم معدات خطوط الأنابيب والخدمات المرتبطة بها لصناعات خطوط الأنابيب ، بما في ذلك المعالجة الكيميائية والنفط والغاز ومعالجة المياه. لضمان الأداء الأمثل والاستخدام الفعال للموارد ، غالبا ما نقدم منتجات مخصصة لتلبية المتطلبات الفريدة لكل مشروع.

إن التزامنا الصارم الذي لا يتزعزع بمراقبة الجودة على مر السنين جعل مؤشرات الخنازير الخاصة بنا مدرجة كمنتجات العلامة التجارية الصينية الوحيدة في المنتجات الاختيارية في مشاريع CNOOC المتعددة. في وقت مبكر من عام 2010 ، بدأنا في توفير المنتجات لمشاريع النفط في منطقة آسيا وأفريقيا وأمريكا اللاتينية ، مع مشاريع طويلة الأجل ومستمرة مثل حقول النفط PDOC و DPOC و Hafaya و Misan و Graf ، ودون تلقي أي ردود فعل سلبية على الجودة. في الوقت الحاضر ، تم الاعتراف بمنتجاتنا أيضا من قبل شركات مثل CCED و Oxy و Aramco السعودية و Shell ، وأصبحت أعضاء في "جمعية منتجات وخدمات الخنازير (PPSA)" ، مما يوفر طريقة أخرى لمقاولي مشاريع الأنابيب للوصول إلى منتجات عالية الجودة وبأسعار معقولة.

So, we remain committed to perpetual self-improvement. We will provide superior quality products and advanced pigging solutions for industrial pipelines, striving tirelessly towards building EMT into an industry benchmark within the pipeline equipment industry.

لا توجد مراجعات بعد.