Understanding Pigging Balls

What are Pigging Balls?

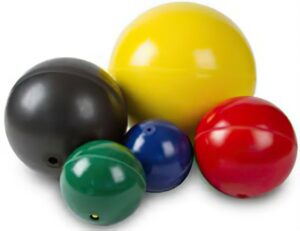

Pigging balls come in a diverse array of sizes, with slight variations to suit different needs. Some pipeline systems are specifically designed to accommodate ball pigs due to specialized pig launchers or the presence of tight bends. While Ball pigs are suitable for certain applications, we usually suggest opting for more robust cup or disc-type pigs when feasible, as they enhance cleaning efficacy and fluid extraction.

The typical hardness for these pigs is 80 Durometer (Long Life Formulation), although Ball Pigs are also offered in various other Durometers. Additionally, inflatable urethane spheres are an option.

Our inventory includes an extensive range of foam balls and balls made from non-polyurethane materials such as Buna and Neoprene. For further details, please refer to the Foam and Miscellaneous sections of this catalog.

مقدمة

Pipeline cleaning and maintenance are crucial for the efficient operation of fluid transport systems. Over time, pipelines can accumulate deposits like scale, wax, or other residues that impede flow and reduce efficiency. To tackle these challenges, the industry relies on various cleaning methods, among which pigging stands out due to its effectiveness and minimal downtime.

The concept of pigging involves using devices known as “pigs” to clean and inspect pipelines. These pigs, particularly pigging balls, travel through the pipeline, pushed by the product flow or a driving force like water or air. As they move, they scrape and sweep away debris, ensuring the pipeline remains free from obstructions and operates at optimum capacity.

Moreover, pigging not only cleans but also provides valuable insights into the condition of the pipeline. It helps detect anomalies such as cracks or leaks, which are crucial for maintaining the safety and longevity of pipeline infrastructure. This dual functionality makes pigging an indispensable tool in modern pipeline maintenance strategies, blending efficiency with critical preventive measures. As we delve deeper, understanding how pigging balls specifically contribute to this process reveals their unique value in maintaining the health and efficiency of pipeline systems.

Parameters of Foam Pigs

| اسم | نموذج | اداء | المعايير الفنية |

| خنزير رغوة استرطابي | LCQZ-RTH | 1. One-time foaming of polyether polyurethane material forms it. | ضغط البداية: 0.2-0.3 ميجا باسكال |

| 2. نسيج ناعم ، ومرونة جيدة. | الكثافة: 35 كجم / متر مكعب ~ 150 كجم / متر مكعب | ||

| 3. لديها أداء قوي لامتصاص الماء. ويمكن أن تصل كمية التشوه إلى 70٪. | تحمل الضغط: 7 ميجا باسكال | ||

| 4. تأثير ملحوظ على نزح المياه وإزالة الشحوم وتجفيف خطوط الأنابيب. | معدل التمدد: 320٪ | ||

| نسبة الضغط: 60 | |||

| الحياة المرنة: 50000 مرة | |||

| معدل الاستنزاف: 4 مم / 100 كم | |||

| مسافة التشغيل: 50 كم ~ 150 كم | |||

| درجة حرارة التشغيل: -30 °C ~ 100 °C |

| خنزير رغوة عارية | LCQZ-RTN | 1. نسيج ناعم ومرونة جيدة. | الضغط الابتدائي: 0.02 ميجا باسكال |

| 2. مع امتصاص الماء القوي ، يمكن أن تصل كمية التشوه إلى 60٪. | الكثافة: 35 كجم / متر مكعب ~ 220 كجم / متر مكعب | ||

| 3. For dewatering, cleaning, and drying pipelines. | تحمل الضغط: 7 ميجا باسكال | ||

| معدل التمدد: 320٪ | |||

| نسبة الضغط: 60 | |||

| الحياة المرنة: 50000 مرة | |||

| معدل الاستنزاف: 4 مم / 100 كم | |||

| مسافة التشغيل: 50 كم ~ 150 كم | |||

| درجة حرارة التشغيل: -30 °C ~ 100 °C |

| بولي رغوة خنزير | LCQZ-RTR | 1. Polyurethane material forms its interior. The surface is coated with a polyurethane elastomer coating. | الضغط الابتدائي: 0.02 ميجا باسكال |

| 2. مرونة جيدة ومقاومة تآكل معينة. | الكثافة: 35 كجم / متر مكعب ~ 220 كجم / متر مكعب | ||

| 3. يمكن أن تصل كمية التشوه إلى 50٪ ، وهو خنزير الرغوة الأكثر استخداما. | تحمل الضغط: 7 ميجا باسكال | ||

| 4. تستخدم لتنقية الأنابيب وإزالة الترسبات وعزل السوائل. | معدل التمدد: 320٪ | ||

| نسبة الضغط: 50 | |||

| الحياة المرنة: 50000 مرة | |||

| معدل الاستنزاف: 2 مم / 100 كم | |||

| مسافة التشغيل: 100 كم ~ 300 كم |

The Role of Pigging Balls in Pipeline Cleaning

Purposes of Using Pigging Balls

Pigging balls serve multiple purposes in pipeline maintenance, primarily focusing on cleaning, inspection, and sealing. For cleaning, they effectively remove accumulated debris and residue, ensuring smooth pipeline operations. During inspections, these balls help identify internal issues like cracks or corrosion, crucial for preventative maintenance. Additionally, they play a significant role in sealing. This function involves the pigging balls creating a tight seal within the pipeline, which is essential for isolating sections for maintenance or leak testing. Each of these applications highlights the versatility and necessity of pigging balls in maintaining the integrity and efficiency of pipeline systems.

How Pigging Balls Work

Pigging balls operate through a straightforward yet effective mechanism within pipelines, primarily focusing on the movement and interaction with internal surfaces and contaminants.

Mechanism of Action Inside Pipelines:

Pigging balls are introduced into the pipeline through a launcher, which is a device specifically designed for this purpose. Once inside, they are propelled forward by the pressure of the fluid behind them, whether it is gas, oil, water, or another medium. As they travel through the pipeline, the elasticity and size of the pigging balls allow them to adjust to variations in the pipeline’s diameter and navigate bends and valves effectively.

The movement of pigging balls within the pipeline is not just forward propulsion; they also roll and spin, which enhances their cleaning action. This dynamic movement ensures that the entire internal surface of the pipeline comes into contact with the pigging balls, allowing for thorough scrubbing and removal of deposits and buildup.

Interaction with Pipeline Contaminants:

The surface of pigging balls is for interacting effectively with various types of contaminants such as sludge, wax, scale, and other deposits that can accumulate in pipelines. The material of the pigging ball, often rubber or foam, is chosen for its abrasiveness and durability, which are critical for removing tough deposits without damaging the pipeline.

As pigging balls sweep through the pipeline, their textured surfaces grab and pull debris from the pipe walls. The balls carry this debris along until they exit the pipeline, at which point workers remove the debris along with the pigs. In some cases, especially in liquid pipelines, the flow of the medium itself flushes out the dislodged contaminants, further cleaning the pipeline.

By maintaining direct contact with all inner surfaces and effectively removing various types of contaminants, pigging balls enhance both the efficiency and safety of pipeline operations. Their use not only helps prevent potential blockages and flow restrictions but also extends the operational life of the pipeline by maintaining its cleanliness and integrity.

خاتمة

Pigging balls play a vital role in maintaining pipeline efficiency and safety. They effectively remove debris and inspect internal conditions, preventing costly downtime and hazardous leaks. These tools are essential for ensuring that pipelines operate smoothly and reliably. Looking ahead, the future of pipeline maintenance looks promising. Innovations in pigging technology are expected to enhance their effectiveness and adaptability. We anticipate smarter, more resilient pigging solutions that can tackle diverse pipeline challenges with even greater precision. This advancement will continue to safeguard the integrity of vital infrastructure, ensuring optimal performance and reliability in various industries.

لا توجد مراجعات بعد.