Introduction to Corrosion Coupon Assembly

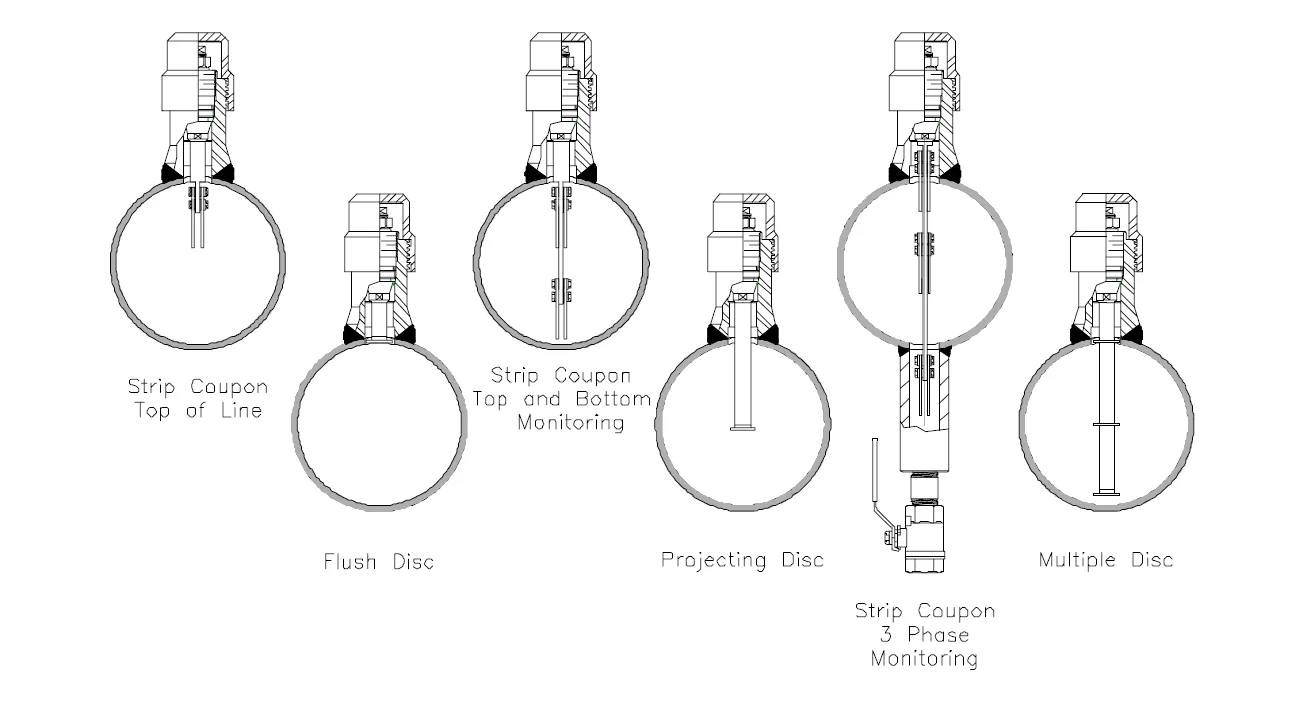

Access fittings serve as a foundational component in the field of corrosion monitoring. They act as gateways, enabling the insertion and retrieval of corrosion coupons from pressurized systems without interrupting operations. Primarily, these fittings are designed to provide a quantitative estimate of corrosion rates. It also offers a window into the health and longevity of industrial systems. Additionally, they facilitate qualitative analysis by allowing visual identification of corrosion types. Thus serving as a dual-purpose tool for comprehensive corrosion assessment.

The Corrosion Coupon

At the heart of the assembly lies the corrosion coupon, a carefully fabricated metal sample that is integral to the process of corrosion evaluation. This coupon is not just any piece of metal. It is a precisely shaped, sized, and crafted specimen with a surface area specifically designed to mimic the inner workings of the process equipment it monitors.

1. Specifications

The specifications of the corrosion coupon are meticulously defined. Its shape, size, and surface area are predetermined to ensure consistent and reliable measurements. The choice of material for the coupon is critical as it closely resembles the chemical composition of the process equipment. Also ensuring that the corrosion it undergoes is representative of the actual conditions within the system.

In addition to its physical and chemical properties, each coupon is distinguished by a unique serial number.Which aids in tracking and documenting the corrosion data over time. This level of detail ensures reproducibility and accountability in the monitoring process.

The exposure of the corrosion coupon to the corrosive medium is carefully timed. It is left within the system for a fixed period, allowing it to undergo the same corrosive effects as the pipelines or vessels it represents. This consistent exposure is crucial as it allows for an accurate comparison over time, ensuring that the data collected is both meaningful and actionable.

2. Product Function

Ultimately, the purpose of the corrosion coupon is twofold. Firstly, it provides a visual indication of corrosion types. Which can be critical for identifying specific corrosive agents and understanding their effects on the system. Secondly, it quantifies the rate of corrosion, offering tangible metrics that can be used to predict the lifespan of the system components, plan maintenance. And taking corrective actions if necessary. This dual functionality makes the corrosion coupon an indispensable tool in the arsenal of corrosion prevention and control.

Product Specifications

The product, specifically crafted for pipeline testing, is known as the Corrosion Coupon Holder Access Fitting. It plays a pivotal role in monitoring and safeguarding pipeline integrity by providing accurate corrosion data. The construction of this essential tool utilizes a variety of robust materials to ensure compatibility with different industrial environments and to meet diverse operational needs.

The materials selected for crafting the access fittings include Stainless Steel 304 and 316, both known for their corrosion resistance and durability. For more demanding environments, DSS F51, Carbon Steel A105N. And the highly corrosion-resistant Inconel 625 are also options, providing a comprehensive range of materials to match the specific conditions of various systems.

Operating within a temperature range of -20 to +120 degrees Celsius. Then the access fittings are designed to withstand substantial thermal variations, ensuring reliability across a multitude of operational scenarios.

Product Features

Ease of operation is a hallmark of this product, ensuring that it can be used effectively by personnel without the need for extensive training. Moreover, the high accuracy of the corrosion data provided by the coupon holder enables precise monitoring of system health, contributing significantly to maintenance strategies and the prevention of unexpected failures.

The longevity of the product is another key feature, designed to endure the harsh conditions of industrial pipeline systems over extended periods. This durability translates into cost savings, as the need for frequent replacements and associated downtime is greatly reduced.

Efficiency is seamlessly integrated with these cost-effective benefits. It making our product a smart choice for companies looking to optimize their operations without incurring high expenses.

Payment Terms

Understanding the financial considerations of their clientele, flexible payment options are provided, including Telegraphic Transfer (TT) and Letter of Credit (LC). These payment alternatives ensure that companies have the latitude to choose the method that best aligns with their financial planning and cash flow management, simplifying the purchasing process and fostering a customer-friendly purchasing environment.

Advantages of EMT’s Corrosion Coupon Assembly

The Corrosion Coupon Assembly designed by EMT offers a host of advantages that cater to the pragmatic needs of industry professionals. Firstly, the assembly boasts a lightweight and flexible design, facilitating effortless handling and installation. Thereby reducing labor intensity and time. Additionally, this design flexibility ensures that the product can be easily adapted to a variety of pipeline configurations. Enhancing its utility across different situations.

Another significant advantage is the product’s effective injection efficiency. This ensures that when the coupon is inserted into the pipeline. It does so in a manner that is both smooth and secure, minimizing disruptions to the system and maintaining the integrity of the testing process.

Furthermore, the assembly is equipped with accurate location tracking capabilities. This feature allows for precise monitoring of the coupon’s position within the system, ensuring that corrosion rates are recorded at the correct locations. And that the data collected is as accurate and relevant as possible.

Installation Instructions

Accompanying the Corrosion Coupon Assembly are comprehensive installation instructions that provide clear guidance for setting up the system. Standard with the product is Delrin insulation. Which boasts a high temperature rating, ensuring the coupon holder’s integrity and performance even under elevated temperatures.

For operations that encounter higher temperature ranges, several options for insulation materials are available. Teflon insulation can withstand temperatures up to 500°F (260°C), Rulon up to 550°F (288°C), and Ceramic up to a remarkable 1472°F (800°C). These options provide the flexibility needed to customize the assembly according to specific operational requirements.

Why Choose EMT’s Corrosion Coupon Assembly

When selecting EMT’s Corrosion Coupon Assembly, you are not just choosing a product but also embracing a service and support system that is dedicated to customer satisfaction. EMT offers a diverse range of product types, each designed to meet the varying requirements of different industries and applications. This diversity ensures that every customer finds a solution that fits their specific needs.

Quality assurance is a cornerstone of EMT’s offerings. Prospective users have the opportunity to test samples, providing them with the confidence that the products they purchase meet the high standards they expect. This sample offering is a testament to EMT’s transparency and commitment to quality.

Moreover, EMT prides itself on providing the fastest possible feedback to customer inquiries and ensuring that delivery times are kept to a minimum. This rapid response is crucial for maintaining operational continuity and minimizing downtime.

Lastly, EMT’s dedication to customer support is exemplified by its continuous availability. With a promise of being online 24/7, customers have the assurance that support is always just a message away. It provides peace of mind that any issues or questions will be promptly addressed. This round-the-clock support underscores EMT’s commitment to excellence in service.

درباره EMT

Shenyang Institute of Sources Technology Development, coupled with Shenyang EMT Piping Technology Co., Ltd.. They are at the forefront as specialized manufacturers in the realms of corrosion monitoring and pipeline cleaning products. Since their establishment in 1993, they have been steadfast in delivering cutting-edge pipeline equipment and comprehensive services to various sectors. It includs chemical processing, oil and gas, and water treatment industries. To cater to the unique demands of each project and ensure the highest levels of performance and resource efficiency. They routinely offer bespoke product solutions tailored to the specific needs of their clients.

Throughout the years, their rigorous and unyielding dedication to maintaining stringent quality control measures has culminated in their pig indicators being distinguished as the exclusive Chinese brand selected for inclusion in the optional product list for numerous projects undertaken by CNOOC. Dating back to 2010, they have expanded their reach, supplying products to oil projects across the Asia, Africa, and Latin America regions. Noteworthy long-term and ongoing projects include PDOC, DPOC, Hafaya, Misan, and Graf oil fields. Impressively, throughout this period. They have consistently upheld a record of positive performance, with no negative quality feedback received.

Join in PPSA

As of the present day, their product excellence has garnered recognition from illustrious companies. Such as CCED, Oxy, Saudi Aramco, and Shell. Adding to their accolades, they have also achieved membership with the esteemed “Pigging Products and Services Association (PPSA),”. Then it provides an additional avenue for pipe project contractors seeking access to cost-effective, high-quality products.

Looking to the future, Shenyang Institute of Sources Technology Development and Shenyang EMT Piping Technology Co., Ltd. reaffirm their unwavering pledge to continuous improvement. In a relentless pursuit of excellence, they are committed to delivering superior quality products and pioneering pigging solutions tailored for industrial pipelines. So their goal remains clear and ambitious. To elevate EMT to the status of an industry benchmark, synonymous with excellence in the pipeline equipment sector.

هنوز هیچ بررسی وجود ندارد.