| نام | Injection Quills | |

| مواد | فولاد ضد زنگ 304 ، فولاد ضد زنگ 316 ، DSS F51 ، فولاد کربن A105N و همچنین Inconel 625 | |

| دمای عملیاتی | -20±120 | |

| ویژگی | اولا، کارکرد آسان | |

| ثانیا، عمر طولانی با دقت بالا | ||

| در نهایت، راندمان بالا، کم هزینه | ||

| پرداخت | TT/LC | |

| مزیت - فایده - سود - منفعت | اولا، آنها سبک و انعطاف پذیر هستند. | |

| ثانیا، راندمان تزریق عالی. | ||

| در نهایت، ردیابی دقیق مکان. |

| مدل | ||||||||||||||||||||||||||||

Si | انژکتور شیمیایی Quill | |||||||||||||||||||||||||||

| Code | پلاگین | |||||||||||||||||||||||||||

| Pxxx | نوع | مواد | Sealing Material | |||||||||||||||||||||||||

| 0 | بدون درخواست | 0 | حسابهای | 0 | بدون درخواست | |||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316 اس اس | 3 | Dss | 1 | بسته بندی اولیه Viton O-Ring / PTFE | |||||||||||||||||||||

| 2 | بدنه پلاگین جامد | 2 | 316 ال اس اس | 4 | Inconel | 2 | HNBR | |||||||||||||||||||||

| Code | مهره تزریق | |||||||||||||||||||||||||||

| Nxx | اندازه اتصال | مواد | ||||||||||||||||||||||||||

| 0 | یعنی بدون درخواست | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | یعنی 1/4 اینچ | 1 | یعنی 316SS | 3 | یعنی DSS | |||||||||||||||||||||||

| 2 | یعنی 1/2 اینچ | 2 | یعنی 316LSS | 4 | یعنی اینکونل | |||||||||||||||||||||||

| –کد | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx" | اندازه اتصال | مواد | نازل | اندازه خط (x") | ||||||||||||||||||||||||

| 0 | بدون درخواست | 0 | حسابهای | 0 | یعنی بدون درخواست | موثرترین موقعیت برای تزریق به طور کلی در مرکز لوله است | ||||||||||||||||||||||

| 1 | یعنی 1/4 اینچ | 1 | یعنی 316SS | 1 | یعنی باز کن | |||||||||||||||||||||||

| 2 | یعنی 1/2 اینچ | 2 | یعنی 316LSS | 2 | یعنی Quill | |||||||||||||||||||||||

| 3 | یعنی DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | یعنی اینکونل | |||||||||||||||||||||||||||

| –کد | Nipple and Valve(or end Flange)of Tee | |||||||||||||||||||||||||||

| Txx | اندازه اتصال | مواد | ||||||||||||||||||||||||||

| 0 | یعنی بدون درخواست | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | یعنی نوک پستان 1/4 اینچ | a | یعنی نوک پستان و شیر 1/4 اینچ | 1 | یعنی 316SS | |||||||||||||||||||||||

| 2 | یعنی نوک پستان 1/2 اینچ | b | یعنی نوک پستان و شیر 1/2 اینچ | 2 | یعنی 316LSS | |||||||||||||||||||||||

| 3 | یعنی نوک پستان 3/4 اینچی | c | یعنی نوک پستان و شیر 3/4 اینچی | 3 | یعنی D SS | |||||||||||||||||||||||

| 4 | یعنی 1 "نوک پستان | d | یعنی 1 اینچ نوک پستان و شیر | 4 | یعنی اینکونل | |||||||||||||||||||||||

| 5 | یعنی فلنج 1/4 اینچ | e | یعنی فلنج انتهای نوک پستان 1/4 اینچ | |||||||||||||||||||||||||

| 6 | یعنی فلنج 1/2 اینچ | f | یعنی فلنج انتهای نوک پستان 1/2 اینچی | |||||||||||||||||||||||||

| 7 | یعنی فلنج 3/4 اینچی | g | یعنی فلنج انتهای نوک پستان 3/4 اینچی | |||||||||||||||||||||||||

| 8 | یعنی فلنج 1 اینچی | h | یعنی فلنج انتهای نوک پستان 1 اینچی | |||||||||||||||||||||||||

| به عنوان مثال، SI-P221-N12-S122-L4"-T22 SI:e.g. Sampling & Injection Assembly, P221: به عنوان مثال بدنه پلاگین جامد در 316LSS Viton O-Ring و بسته بندی اولیه PTFE ، N12:e. g. injection Nut Connection Size is 1/4″and مواد است 316LSS ، S122:e. g. injection لوله اندازه اتصال 1/4 اینچ است و مواد است 316LSS. نوع نازل quiills است L4 ": برای لوله 4 اینچی. تی 22: نوک پستان اندازه اتصال سه راهی 1/2 اینچ است، مواد نوک پستان است 316 ال اس اس | ||||||||||||||||||||||||||||

1. Introduction to Injection Quills

Injection Quills serve a crucial role across various industries, providing a controlled method for introducing treatment chemicals into pressurized process streams. These precision devices are indispensable in sectors such as oil and gas, chemical processing, and water treatment, where maintaining the integrity and efficiency of the flow systems is paramount.

2. Purpose of Injection Quills in Industry

The primary purpose of Injection Quills is to inject chemicals directly into a pipeline or vessel to prevent issues such as corrosion, scaling, or biological growth. By doing so, they protect the system from damage, improve product quality, and ensure compliance with environmental standards. Industries rely on these quills for their precision and effectiveness in chemical dispersion, which is critical for the longevity and reliability of their operations.

3. Common Applications in Oil and Gas, Chemical Processing, and Water Treatment

In the oil and gas sector, Injection Quills are vital for introducing corrosion inhibitors to safeguard pipeline infrastructure. Chemical processing facilities utilize them to dose reactants or catalysts precisely, optimizing reaction outcomes. In water treatment, quills play a central role in disinfecting and conditioning the water, ensuring that it meets both safety and quality guidelines.

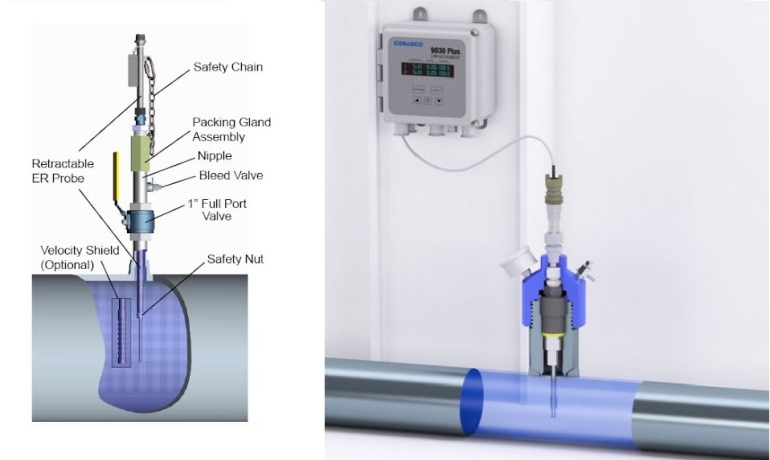

4.Design and Functionality

Injection Quills are expertly designed to introduce chemicals into pressurized streams with remarkable precision. They feature a slender insertion point that extends into the central flow path of the pipeline, ensuring that chemicals are evenly mixed into the process fluid. So this central placement is key to the effective dispersion of treatment agents and helps to prevent the chemicals from settling on the pipe walls, where they could create concentrated areas that might lead to corrosion or other integrity issues.

5. Importance of Central Placement for Effective Chemical Mixing

The strategic central placement of Injection Quills is critical for achieving optimal mixing and dilution of chemicals within the process stream. By positioning the quill correctly, it ensures that the injected chemicals are rapidly integrated into the high-velocity flow, promoting uniform distribution and immediate interaction with the process fluid.

6. Prevention of Chemical Adherence to Pipeline Walls

The design of Injection Quills actively prevents the chemicals from adhering to the pipeline walls, which is a common challenge with direct injections. This not only maintains the quality and effectiveness of the chemical treatment but also protects the pipeline material from potential damage due to high concentrations of chemicals at any given point. As a result, Injection Quills are a fundamental component in maintaining the smooth and safe operation of industrial pipelines and vessels.

7. Key Features of Injection Quills

Targeted Chemical Delivery

Firstly, Injection Quills excel in delivering chemicals with precision, ensuring they enter the process stream at the most effective location. This targeted approach maximizes the effectiveness of the chemical treatment, optimizing process outcomes and promoting system efficiency.

Material Construction

Then, crafted from materials resistant to a broad spectrum of chemicals and operating conditions, Injection Quills withstand the rigors of industrial environments. This resilience ensures compatibility with different chemicals, providing a versatile solution across various sectors without compromising on durability.

Customization Capabilities

At last, recognizing the unique demands of each process, Injection Quills offer extensive customization options. They can be tailored in length and equipped with a variety of nozzle types to meet the specific needs of the process, ensuring an optimal fit and performance.

8. Safety and Efficiency Enhancements

Integrated Check Valve

Each Injection Quill incorporates a check valve, a critical feature that actively prevents the backflow of process fluid. This valve plays a vital role in maintaining the chemical integrity, ensuring accurate dosing and enhancing the overall safety of the chemical injection system.

Installation Advantages

Because they are designed with a focus on ease of integration, Injection Quills facilitate a straightforward installation process. So this minimally invasive design allows for quick incorporation into existing systems, minimizing disruption and downtime, thereby maintaining continual process

9. Industrial Applications

Use Cases

Because Injection Quills are instrumental in a variety of industrial applications. So they are paramount in the delivery of corrosion inhibitors, ensuring the longevity of pipelines by mitigating corrosive processes. In biocide delivery, quills ensure the precise dosage necessary to prevent biological growth, which can compromise the integrity of fluid systems. Additionally, they play a crucial role in pH adjustment, neutralizing acidic or alkaline waters to prevent damage to equipment and ensure compliance with environmental discharge regulations.

Impact on System Integrity

Injection Quills are guardians of system integrity, actively contributing to the preservation and efficiency of industrial processes. By ensuring that chemicals are accurately and evenly introduced into the system, quills prevent localized concentrations that can lead to equipment wear or failure. Their use ensures that chemical treatments are more effective, thus extending the lifespan of assets and maintaining consistent process performance.

نتیجه

In summary, Injection Quills are vital components in the realm of industrial chemical processes. Then their capacity to deliver treatment chemicals in a controlled and precise manner makes them indispensable for maintaining the integrity and efficiency of industrial operations. The strategic application of Injection Quills significantly contributes to operational excellence, positioning them as critical tools for any process that involves chemical treatment. So their role in ensuring the longevity and peak performance of industrial systems cannot be overstated.

10. Our Service

1. Firstly, there are many kinds of chemical injection access fitting with different type to meet difference requirements.

2. Secondly, samples will be offered to attest to the quality and our services.

3. And then the fastest feedback!

4. After that, the fastest delivery time.

5. At last, 24 hours,7 days online.

11. Introduction of EMT

موسسه توسعه فناوری منابع شنیانگ و Shenyang EMT Piping Technology Co.، Ltd. تولید کنندگان تخصصی محصولات برای نظارت بر خوردگی و تمیز کردن خط لوله هستند. از زمان اغاز ما در سال 1993، ما تجهیزات خط لوله و خدمات مرتبط با ان را به صنایع خط لوله، از جمله پردازش شیمیایی، نفت و گاز و تصفیه اب ارائه داده ایم. برای اطمینان از عملکرد مطلوب و استفاده کارامد از منابع، ما اغلب محصولات سفارشی را برای پاسخگویی به نیازهای منحصر به فرد هر پروژه ارائه می دهیم.

تعهد دقیق و تزلزل ناپذیر ما به کنترل کیفیت در طول سال ها باعث شده است که شاخص های خوک ما به عنوان تنها محصولات با نام تجاری چینی در محصولات اختیاری در چندین پروژه CNOOC ذکر شده است. در اوایل سال 2010، ما شروع به ارائه محصولات برای پروژه های نفتی در منطقه اسیا، افریقا و امریکای لاتین، با پروژه های بلند مدت و در حال انجام مانند PDOC، DPOC، Hafaya، Misan و Graf و بدون دریافت بازخورد کیفیت منفی کردیم. در حال حاضر، محصولات ما نیز توسط شرکت هایی مانند CCED، Oxy، Saudi Aramco و Shell شناخته شده است و عضو "انجمن محصولات و خدمات Pigging (PPSA)" شده است، ارائه راه دیگری برای پیمانکاران پروژه لوله برای دسترسی به محصولات مقرون به صرفه و سطح بالا.

So, we remain committed to perpetual self-improvement. We will provide superior quality products and advanced pigging solutions for industrial pipelines, striving tirelessly towards building EMT into an industry benchmark within the pipeline equipment industry.

هنوز هیچ بررسی وجود ندارد.