The EMT-CP-0 Resistance Corrosion Online Detection System

The EMT-CP-0 online corrosion monitoring remote data collection is a crucial component within the resistance corrosion online detection system, which is dedicated to real-time corrosion monitoring. Initially, it operates by precisely measuring variations in the electrical resistance of a پروب خوردگی‘s sensitive elements. These elements gradually thin out as corrosion takes place.

Moreover, these sensitive elements are constructed from materials that closely resemble those used in the pipelines or equipment being monitored. Consequently, by meticulously tracking the degree to which these elements thin over time, the system can reliably estimate the corrosion rate of the actual pipeline or equipment. This method provides a continuous assessment of corrosion, effectively eliminating the need for manual inspection.

Furthermore, the EMT-CP-0 is designed with an explosion-proof structure. This particular design element makes it exceptionally suitable for the potentially hazardous environments commonly encountered in the petrochemical industry.

What is Corrosion Monitoring?

Corrosion monitoring refers to the use of specialized tools and techniques to measure the corrosion rate of a system. Like some plumbing systems, it will affect the working process because of corrosion. Corrosion test results are usually reported annually in millimeters. By analyzing the corrosion detection results, the corresponding measures are taken. To help maintain and protect infrastructure.

Corrosion monitoring can monitor the rate of metal wear. The cause of wear and tear is usually a chemical reaction in the surrounding environment. These measurements help keep the system safe and durable. It also prevents leakage due to corrosion from causing harm to the environment.

The Difference Between Corrosion Inspection And Corrosion Monitoring

Corrosion inspection and corrosion monitoring are often confused, but they serve distinct functions. Corrosion inspection is a periodic assessment where equipment or infrastructure is checked at specific intervals for signs of corrosion and to measure any deviations from expected conditions. The goal of inspection is to evaluate the extent of corrosion to determine if repairs or replacements are needed.

On the other hand, corrosion monitoring, such as with the EMT-CP-0 Online Corrosion Monitoring Remote Data Collection system, is an ongoing process that continuously tracks corrosion levels. This continuous surveillance allows for immediate action to control and mitigate corrosion as it happens. Monitoring aims not just to detect corrosion but to manage and prevent it by improving preventative strategies in real-time.

The EMT-CP-0 Remote Data Collection

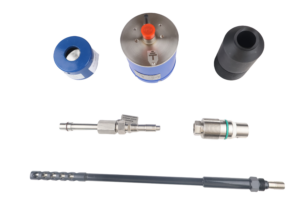

The EMT-CP-0 system’s components include power, control, and data modules. They work in sync for effective information processing. At manufacture, an ID configures the system for immediate use. This unique ID streamlines setup and aids accurate data management. The EMT-CP-0’s modular nature allows for straightforward servicing and enhancements. This flexibility extends its service life and ensures steady performance in various settings. The system’s design, with its unique ID and modular components, ensures easy integration and reliable operation across a range of applications.

Signal Transmission in the EMT-CP-0 System

The Remote Data Collection offers two signal transmission methods:

- It can use a two-wire system where the on-site DC24V power supply powers it and it outputs either an RS485 signal or a 4-20mA signal.

- Alternatively, it can operate wirelessly using Bluetooth, powered by an internal lithium battery, storing data internally and allowing download via an explosion-proof Bluetooth device.

The EMT-CP-0 system provides two efficient signal transmission options. Users can choose a wired connection with a DC24V power supply for RS485 or 4-20mA output. They can also select a wireless Bluetooth connection with a self-contained battery for flexible data access and transfer.

Technical Advantages of the EMT-CP-0 System

The EMT-CP-0 system has minimal medium interaction and measures corrosion in liquids, gases, and their mixtures effectively.

EMT-CP-0 System Performance Parameters

محدوده: 0 ~ 261144 واحدهای عمر پروب؛

محدوده امپدانس عنصر حساس به پروب: 1 ~ 50mΩ.

Resolution: Typical value: 1nm (The total thickness of a typical probe-sensitive element is 20 mil, with a lifespan of 10 mils).

منبع تغذیه: منبع تغذیه 24VDC / باتری لیتیومی.

مصرف فعلی: 12mA@24VDC / 1 ~ 12mA@8.4V؛

ارتباطات: RS485 دو سیم، نرخ 2400 باود / 2.4G، LORA، 4G/5G یا 4-20mA

RS485 آدرس: 0 ~ 31

دمای محیط: -40 °C ~ + 70 °C

سطح حفاظت از محفظه: IP 65

حداکثر نرخ جمع آوری: یک بار در دقیقه

حداقل نرخ جمع آوری: یک بار در هر فاصله زمانی

صدور گواهینامه منطقه خطرناک: Ex d IICT4 GB

Conclusion/ Summary

In summary, the EMT-CP-0 system excels at monitoring corrosion in real time. It works well in various environments, including explosive ones. Its use in the petrochemical industry is essential. The system monitors liquids, gases, and mixtures with precision.

Setting up the system is simple, thanks to a unique ID for each unit. It offers both wired and wireless data access. Its specifications provide detailed corrosion data. This allows for quick, informed actions to maintain infrastructure.

The EMT-CP-0 Online Corrosion Monitoring Remote Data Collection moves the focus from periodic checks to ongoing monitoring. This shift helps actively prevent corrosion. Equipment lasts longer, and operational downtime decreases.

هنوز هیچ بررسی وجود ندارد.