Introduction to Pigging Launchers

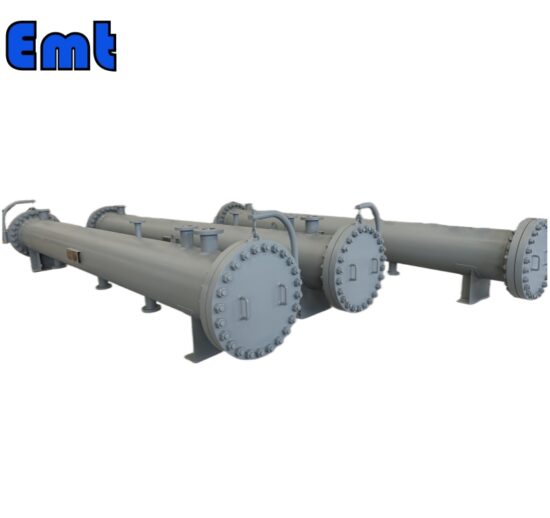

Pigging launcher plays a crucial role in the maintenance of pipelines. These devices introduce pigs into the pipeline system to perform various cleaning and inspection tasks. Pigs are tools or devices that travel through the pipeline, driven by the product flow or a separate propulsion system. The primary purpose of pigging launchers is to insert these pigs without interrupting the pipeline’s operation.

The importance of pigging launchers in pipeline maintenance cannot be overstated. They ensure the smooth operation of pigging processes, which are essential for maintaining the integrity and efficiency of pipelines. Regular use of pigs helps to remove deposits, contaminants, and buildup that can reduce the pipeline’s efficiency and increase the risk of blockages or corrosion.

Understanding the pigging process

Understanding the pigging process reveals its multiple benefits. Once launched, pigs travel along the pipeline, cleaning or inspecting the interior surfaces. This operation helps to prevent potential operational disruptions caused by sediment buildup, which can lead to decreased flow rates, increased pressure, and even pipeline failure. Moreover, pigging enhances safety by helping to prevent leaks that could result from corrosion or damage.

Additionally, pigging is a cost-effective maintenance strategy. It minimizes the need for chemical cleaning agents and reduces downtime by allowing pipelines to remain in operation during cleaning or inspection. This efficiency not only saves time but also reduces environmental impact, as fewer chemicals mean less potential contamination.

In summary, pigging launchers are indispensable in the ongoing maintenance and operation of pipelines. They enable the regular deployment of pigs, which maintain the internal cleanliness and inspection standards necessary for efficient and safe pipeline operations. Thus, the strategic use of pigging launchers contributes significantly to the longevity and reliability of pipeline systems.

مولفه های

| Technical parameters: | |

| 1) Design pressure: | pn1.6-16mpa (35MPa). |

| 2) Design temperature: | 60 ℃. |

| 3) Test pressure: | the water pressure is 1.5 times the design pressure. |

| 4) Nominal diameter: | dn80-dn1400. |

| 5) Corrosion allowance: | 2mm. |

| 6) Seismic fortification crack degree: | 7 degrees. |

| 7) Applicable media: | petroleum, product oil, chemical raw materials, water, and natural gas. |

| 8) Design service life: | 30 years. |

شرایط طراحی

| شرایط طراحی | ||

| 1 | اندازه خط لوله | از 6 اینچ تا 56 اینچ |

| 2 | کد طراحی | ASME هشتم دیو 1; ASME B31.3; ASME B31.4; ASME B31.8 و غیره |

| 3 | فاکتور طراحی | 0.5 ، 0.6 ، 0.7 و غیره |

| 4 | کمک هزینه خوردگی | 0-5mm or more |

| 5 | فشار طراحی | CL150 ، CL300 ، CL600 ، CL900 ، CL1500 ، CL2500 یا در صورت لزوم. |

| 6 | دمای طراحی (حداقل/حداکثر) | -50 درجه سانتی گراد / 200 درجه سانتی گراد |

| 7 | نوع بسته شدن | نوع حلقه گیره بسته شدن سریع باز شدن |

| 8 | جهت نصب | افقی، عمودی و شیبدار |

| 9 | متوسط قابل اجرا | گاز، نفت، نفت، مواد شیمیایی، آب و غیره. |

| ساختار و مواد اصلی | ||

| 1 | بشکه اصلی / حداقل بشکه | ASTM A106 ، ASTM A516 Gr.70 یا در صورت لزوم. |

| 2 | ASTM A515 Gr.70 ، ASTM A516 Gr.70 ، | |

| بسته شدن سریع باز | ||

| (با سیستم اینترلاک) | و ASTM A105 ، ASTM A350 LF2 Class1 ، | |

| ASTM A694 F42 F46 F48 F50 F52 F56 F60 F65 F70 ، | ||

| یا در صورت لزوم. | ||

Benefits and Applications of Pigging Launchers

Pigging launcher significantly enhances pipeline cleaning and maintenance, proving indispensable in modern pipeline operations. They efficiently remove accumulated debris and contaminants that can hinder flow and compromise pipeline integrity. By clearing out these obstructions, pigging launchers ensure smoother, more efficient pipeline operations.

Additionally, these devices play a vital role in preventing corrosion and scale buildup. Regular pigging prevents the accumulation of corrosive substances and mineral deposits, which can lead to costly repairs and maintenance if left unchecked. This proactive approach maintains the pipeline’s condition and extends its operational lifespan.

Switching to product transfer optimization, pigging launchers also dramatically improve the efficiency of transferring products through pipelines. They minimize the amount of product that remains in the pipeline after transfer, thereby reducing waste and enhancing the overall efficiency of the pipeline system. This reduction in leftover product also decreases the need for cleaning, thus reducing downtime and boosting productivity.

Moreover, pigging launchers improve product quality and yield. By ensuring that pipelines are clean and free from contaminants that could mix with the product, these systems help maintain the purity and integrity of the transferred materials. This is especially critical in industries where product purity is paramount, such as in pharmaceuticals and food processing.

In conclusion, pigging launcher offers a multitude of benefits that make them essential in modern pipeline operations. From enhancing operational efficiency and product quality to reducing downtime and extending pipeline life, the advantages of implementing pigging launchers are clear. These devices not only optimize product transfer but also ensure the ongoing health and efficiency of pipeline infrastructure.

نتیجه

In conclusion, pigging launcher is foundational to the cutting-edge management and upkeep of pipeline systems. These devices streamline operations, ensuring that pipelines operate at peak efficiency and safety. By deploying pigging launchers, companies can significantly reduce operational costs and enhance productivity. They prevent costly disruptions and maintain the integrity of the product during transfer. Ultimately, the strategic adoption of pigging launchers is not just a best practice but a crucial investment in the sustainability and profitability of pipeline operations. This technology stands as a testament to the potential for innovation to drive industry standards forward, ensuring a more reliable and efficient future for pipeline management.

هنوز هیچ بررسی وجود ندارد.