1. EMT Pigging Chemical Injection Quills

EMT Pigging proudly presents its Chemical Injection Quills, essential tools designed to uphold the integrity of industrial pipelines through precise chemical management. These quills are crucial for a variety of maintenance tasks, ensuring that pipelines across multiple industries operate safely and efficiently.

| Nom | Plumes d’injection | |

| Matériel | Acier inoxydable 304, acier inoxydable 316, DSS F51, acier au carbone A105N, et aussi Inconel 625 | |

| Température de fonctionnement | -20±120 | |

| Caractéristique | Tout d’abord, une utilisation facile | |

| Deuxièmement, haute précision et longue durée de vie | ||

| Enfin, haute efficacité, faible coût | ||

| Paiement | TT/LC | |

| Avantage | Tout d’abord, ils sont légers et flexibles. | |

| Deuxièmement, une excellente efficacité d’injection. | ||

| Enfin un suivi précis de la localisation. |

| Modèle | ||||||||||||||||||||||||||||

SI | Plume d’injecteur chimique | |||||||||||||||||||||||||||

| -Code | Bouchon | |||||||||||||||||||||||||||

| Pxxx | Type | Matériel | Scellement Matériel | |||||||||||||||||||||||||

| 0 | Aucune demande | 0 | CS | 0 | Aucune demande | |||||||||||||||||||||||

| 1 | Creux Corps de la prise | 1 | 316SS | 3 | DSS | 1 | Joint torique Viton / Garniture primaire en PTFE | |||||||||||||||||||||

| 2 | Corps de prise solide | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| –Code | Écrou d’injection | |||||||||||||||||||||||||||

| Nxx | Taille de la connexion | Matériel | ||||||||||||||||||||||||||

| 0 | c’est-à-dire aucune demande | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | c’est-à-dire 1/4" | 1 | c’est-à-dire 316SS | 3 | c’est-à-dire le DSS | |||||||||||||||||||||||

| 2 | c’est-à-dire 1/2" | 2 | c’est-à-dire 316LSS | 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||

| –Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx" | Taille de la connexion | Matériel | Buse | Taille de ligne (x") | ||||||||||||||||||||||||

| 0 | Aucune demande | 0 | CS | 0 | c’est-à-dire aucune demande | La position la plus efficace pour l’injection se situe généralement au centre du tuyau | ||||||||||||||||||||||

| 1 | c’est-à-dire 1/4" | 1 | c’est-à-dire 316SS | 1 | c’est-à-dire ouvert | |||||||||||||||||||||||

| 2 | c’est-à-dire 1/2" | 2 | c’est-à-dire 316LSS | 2 | c’est-à-dire Quill | |||||||||||||||||||||||

| 3 | c’est-à-dire le DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||||||

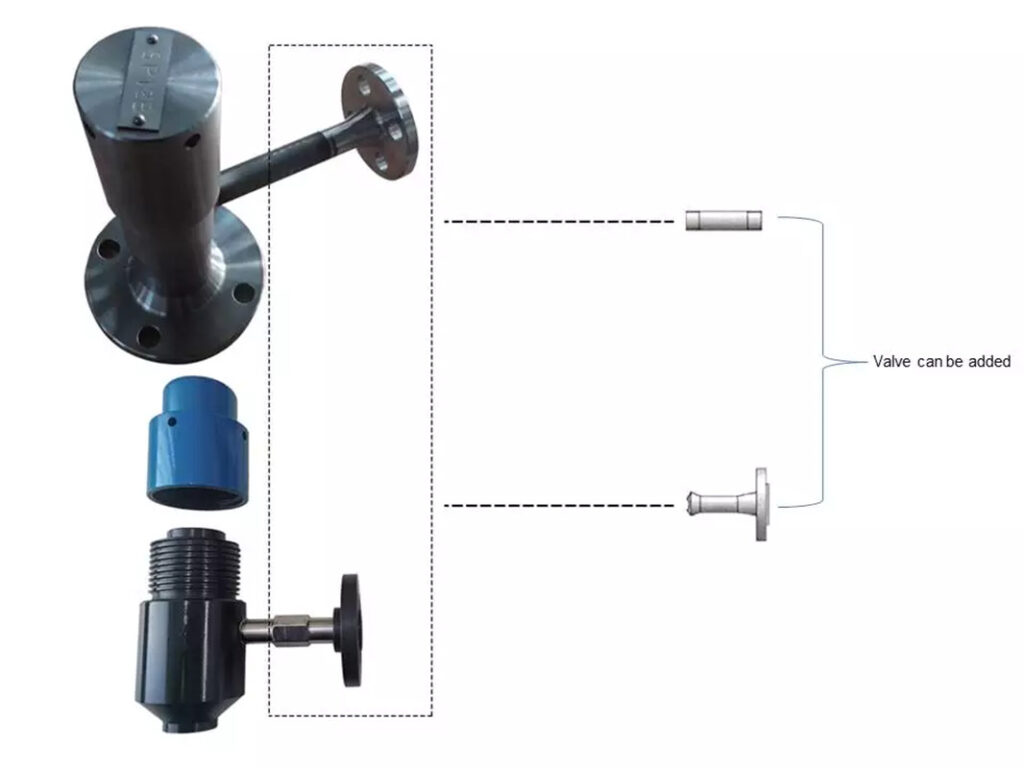

| –Code | Mamelon et valve(ou fin bride) du té | |||||||||||||||||||||||||||

| Txx | Taille de la connexion | Matériel | ||||||||||||||||||||||||||

| 0 | c’est-à-dire aucune demande | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | c’est-à-dire mamelon de 1/4 po | un | c’est-à-dire mamelon et valve de 1/4 po | 1 | c’est-à-dire 316SS | |||||||||||||||||||||||

| 2 | c’est-à-dire mamelon de 1/2 po | b | c’est-à-dire mamelon et valve de 1/2 po | 2 | c’est-à-dire 316LSS | |||||||||||||||||||||||

| 3 | c’est-à-dire mamelon 3/4" | c | c’est-à-dire mamelon et valve 3/4" | 3 | c’est-à-dire D SS | |||||||||||||||||||||||

| 4 | c’est-à-dire 1" Mamelon | d | c’est-à-dire mamelon et valve de 1 po | 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||

| 5 | c’est-à-dire bride 1/4" | e | c’est-à-dire 1/4" Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 6 | c’est-à-dire 1/2" Bride | f | c’est-à-dire 1/2 "Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 7 | c’est-à-dire bride 3/4" | g | c’est-à-dire 3/4 "Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 8 | c’est-à-dire bride de 1 " | h | c’est-à-dire 1" Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| For Example, SI-P221-N12-S122-L4″-T22SI:e.g. Sampling & Injection Assembly. P221: e.g. Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing. N12:e. g. injection Nut Connection Size is 1/4″and Le matériau est 316LSS. S122:e. g. injection Tube La taille de la connexion est de 1/4" et Le matériau est 316LSS.Type of nozzle is quills. L4 » :Pour tuyau de 4 ». T22 : Mamelon de la taille de la connexion en T est de 1/2", Le matériau de l’écrou est 316LSS. | ||||||||||||||||||||||||||||

2. Key Attributes

Versatile Industry Applicability:

Our Chemical Injection Quills are not limited to a single sector. They excel across multiple industries including Building Material Shops. Construction Works, Energy & Mining, pipeline pigging, and oil & gas pipeline maintenance. This versatility underscores their fundamental role in a broad array of industrial applications.

Product Specifications and Weight:

Each quill, with a manageable weight of 4 KG, is engineered to the highest specifications. Our meticulous attention to detail ensures that each quill is built to perform its function flawlessly.

Assured Quality and Testing:

We guarantee the integrity of our quills with a rigorous inspection and testing protocol. Including video outgoing-inspections and thorough machinery test reports, instilling confidence in their performance and reliability.

Proud Origins and Solid Warranty:

Originating from the industrious region of Liaoning, China. Our quills have a solid 1.5-year warranty. Which reflects our trust in their enduring quality.

Recognizable Brand and Product Identity:

EMT Pigging stands behind each Chemical Injection Quill, marked by our trusted brand name and the assurance of our ISO9001 certification—your assurance of our commitment to quality.

Robust Materials and Ingenious Design:

Crafted from the finest materials such as 316L stainless steel and Fluororubber sealing, our quills are designed to withstand operational temperatures of -20~200℃ and pressures from 150LB to 1500LB, ensuring they can handle the most demanding environments.

3. Importance in Pipeline Maintenance

Ensuring Pipeline Integrity:

Chemical injection is integral to maintaining pipeline integrity. Our quills facilitate the precise delivery of chemicals, crucial for the effective treatment and protection of your pipelines.

Corrosion Control and Prevention:

By delivering inhibitors and other treatment chemicals directly into the pipeline, our quills help to minimize and control corrosion, a leading cause of pipeline degradation.

Customized to Your Needs:

Adaptable to a range of operational conditions, our quills can be customized to meet the unique requirements of your pipeline system, ensuring seamless integration and optimal performance.

Wide Operational Range:

EMT Pigging’s Chemical Injection Quills are to operate across a wide temperature and pressure range. This adaptability ensures that regardless of the operating environment. Our quills will deliver consistent and reliable performance.

In summary, EMT Pigging’s Chemical Injection Quills are engineered to enhance the maintenance and longevity of industrial pipelines. Their robust construction, coupled with our commitment to quality and customer service. It makes them an ideal choice for your chemical management needs. We invite you to explore these solutions further and see how they can benefit your operations. Contact us to engage with our team and start optimizing your pipeline maintenance today.

4. Service Commitment

Extensive Selection of Quills:

EMT Pigging stands out by offering a comprehensive selection of chemical injection quills. Each designed to meet the distinct needs of various industrial applications. Our commitment to providing a diverse portfolio ensures that you can find the perfect match for your specific chemical injection requirements.

Quality Verification through Samples:

Understanding that seeing is believing. We extend the opportunity to test our quills before committing fully. By offering sample quills for evaluation, we ensure that you can verify the quality and compatibility of our products with your systems. And guaranteeing peace of mind and satisfaction.

Rapid Response Guarantee:

We are dedicated to providing immediate and meaningful feedback to all customer inquiries. Our team responds swiftly, ensuring that your questions and concerns are addressed with the urgency they deserve.

Speedy Delivery Commitment:

Recognizing the importance of timely operations in your business. Then we promise the fastest delivery times in the industry. Our logistical processes are optimized to ensure that your orders arrive when you need them. Keeping your operations running smoothly.

Round-the-Clock Support:

At EMT Pigging, we believe that support should be as reliable as our products. That’s why our customer service team is available 24/7. Ready to offer assistance and resolve any issues you may encounter, regardless of the time or day.

5. Conclusion and Call to Action

Benefits of EMT Pigging Quills:

In summary, our Chemical Injection Quills are not just products. But solutions designed to enhance the efficiency and longevity of your pipeline maintenance. With their robust design, ease of use, and ability to withstand a wide range of operational conditions. They represent a smart investment for any industry requiring precise chemical management.

Tailored Solutions and Customer Service:

We warmly invite you to explore the tailored solutions and exceptional customer service offerings that define EMT Pigging. Our team is eager to collaborate with you to determine the best-fit products for your needs. Which ensuring that you receive the most efficient and effective solutions available.

Engage with Us for Custom Requirements:

Should you have specific design requirements or product specifications, do not hesitate to contact us. We are committed to innovation and customization. And we welcome the opportunity to design a product that aligns perfectly with your unique operational challenges.

Choose EMT Pigging for Assurance in Quality:

By choosing EMT Pigging, you’re opting for a partner known for reliability and quality in pipeline maintenance. We encourage you to take the next step and reach out to us. Let’s work together to safeguard the integrity of your pipeline systems and enhance your operational efficiency.

Il n’y a pas encore d’avis.