EMT Pigging’s Chemical Injections in Oil and Gas are expertly designed to enhance precision and safety in chemical injection processes—vital for the upkeep of industrial pipelines. These quills deliver chemicals directly and controlledly into the pipeline’s center, which is paramount for effective dispersion and absorption.

Modèle | ||||||||||||||||||||||||||||

| SI | Chemical Injection in Oil and Gas Access Fitting | |||||||||||||||||||||||||||

| -Code | Bouchon | |||||||||||||||||||||||||||

| Pxxx | Type | Matériel | Matériau d’étanchéité | |||||||||||||||||||||||||

| 0 | Aucune demande | 0 | CS | 0 | Aucune demande | |||||||||||||||||||||||

| 1 | Corps de bouchon creux | 1 | 316SS | 3 | DSS | 1 | Joint torique Viton / Garniture primaire en PTFE | |||||||||||||||||||||

| 2 | Corps de prise solide | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| Code | Écrou d’injection | |||||||||||||||||||||||||||

| Nxx | Taille de la connexion | Matériel | ||||||||||||||||||||||||||

| 0 | c’est-à-dire aucune demande | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | c’est-à-dire 1/4" | 1 | c’est-à-dire 316SS | 3 | c’est-à-dire le DSS | |||||||||||||||||||||||

| 2 | c’est-à-dire 1/2" | 2 | c’est-à-dire 316LSS | 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||

| –Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx" | Taille de la connexion | Matériel | Buse | Taille de ligne (x") | ||||||||||||||||||||||||

| 0 | Aucune demande | 0 | CS | 0 | c’est-à-dire aucune demande | La position la plus efficace pour l’injection se situe généralement au centre du tuyau | ||||||||||||||||||||||

| 1 | c’est-à-dire 1/4" | 1 | c’est-à-dire 316SS | 1 | c’est-à-dire ouvert | |||||||||||||||||||||||

| 2 | c’est-à-dire 1/2" | 2 | c’est-à-dire 316LSS | 2 | c’est-à-dire Quill | |||||||||||||||||||||||

| 3 | c’est-à-dire le DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||||||

| –Code | Nipple and Valve (or End Flange) of the Tee | |||||||||||||||||||||||||||

| Txx | Taille de la connexion | Matériel | ||||||||||||||||||||||||||

| 0 | c’est-à-dire aucune demande | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | c’est-à-dire mamelon de 1/4 po | un | c’est-à-dire mamelon et valve de 1/4 po | 1 | c’est-à-dire 316SS | |||||||||||||||||||||||

| 2 | c’est-à-dire mamelon de 1/2 po | b | c’est-à-dire mamelon et valve de 1/2 po | 2 | c’est-à-dire 316LSS | |||||||||||||||||||||||

| 3 | c’est-à-dire mamelon 3/4" | c | c’est-à-dire mamelon et valve 3/4" | 3 | c’est-à-dire D SS | |||||||||||||||||||||||

| 4 | c’est-à-dire 1" Mamelon | d | c’est-à-dire mamelon et valve de 1 po | 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||

| 5 | c’est-à-dire bride 1/4" | e | c’est-à-dire 1/4" Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 6 | c’est-à-dire 1/2" Bride | f | c’est-à-dire 1/2 "Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 7 | c’est-à-dire bride 3/4" | g | c’est-à-dire 3/4 "Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 8 | c’est-à-dire bride de 1 " | h | c’est-à-dire 1" Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| P221 : par exemple corps de bouchon solide en joint torique en Viton 316LSS et garniture primaire en PTFE N12: e.g., injection Nut Connection Size is 1/4″and Material is316LSS, S122:e.g. injection The tube connection size is 1/4 ″ and the material is 316LSS. The type of nozzle is quills L4 » :Pour tuyau de 4 ». T22:Nippleof Tee Connection Size is 1/2″,Nipple material is316LSS | ||||||||||||||||||||||||||||

1. Key Features and Benefits:

Materials:

Crafted from robust materials such as Stainless Steel 304, 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625, these quills are built to withstand harsh conditions and ensure lasting durability.

Operating Temperature:

Functioning across a broad temperature spectrum from -20 to +120 degrees Celsius, the quills accommodate a variety of industrial applications and diverse thermal environments.

Design Efficiency:

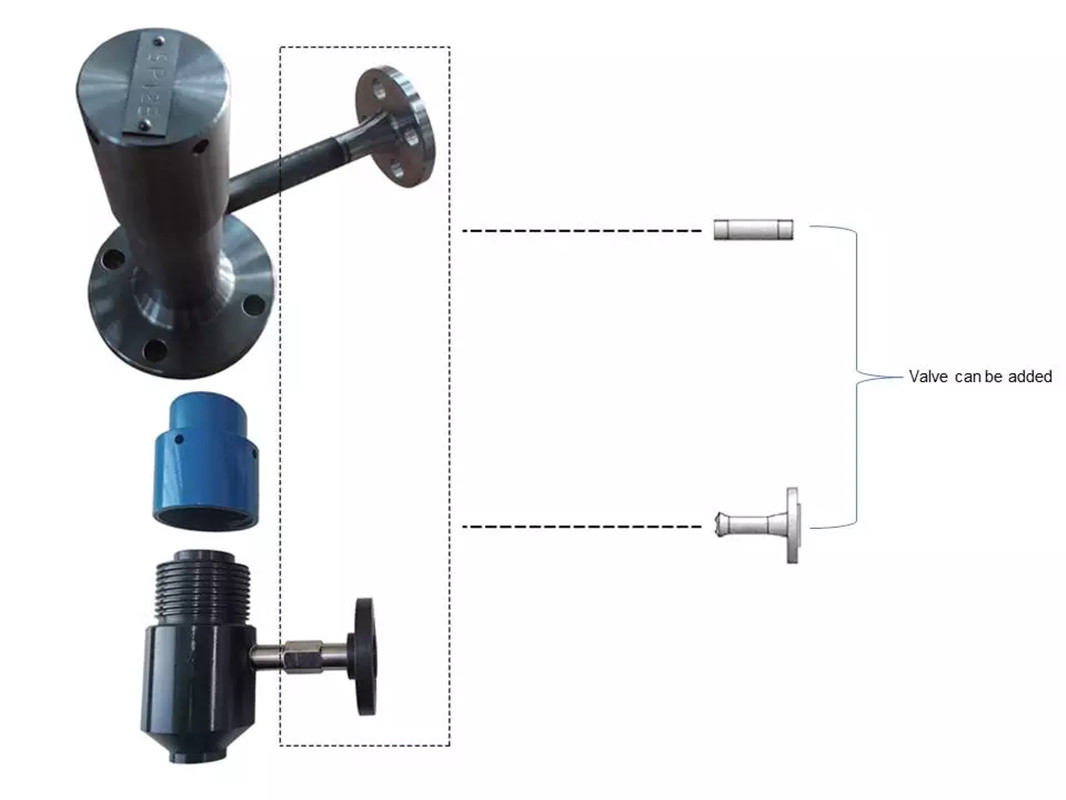

Featuring ease of operation, high precision, and extended lifespan, the quills not only achieve high efficiency but also keep operational costs low. Their design includes versatile mounting options—like 2″ flange, 2″ Flareweld access fitting, and 1″ Nipple to NPT ball valve—to adapt to different pipeline configurations.

Avantages:

Their lightweight and flexible construction stands out, enhancing injection efficiency and ensuring precise location tracking for consistent chemical distribution.

Part of the EMT Injection System, these Chemical Injections in Oil and Gas are indispensable for the safe and reliable injection of inhibitors and other chemicals under live operating pressures. This system is crucial for preventing corrosion and maintaining smooth pipeline operations.

With various nozzle types available, the quills demonstrate versatility to meet specific injection needs. The samplers, running parallel to the injectors, provide consistent and reliable sampling for ongoing monitoring and maintenance.

2. Customer Service Commitment:

Selection:

We provide a wide array of chemical injection quills, ensuring a fit for every unique application.

Quality Assurance:

Sample availability allows you to verify quality and efficiency, guaranteeing satisfaction before any purchase.

Responsiveness:

We take pride in our rapid response to client inquiries and concerns.

Delivery:

Committed to promptness, we assure the fastest delivery times to minimize disruption to your operations.

Support:

With 24/7 customer service, we offer uninterrupted assistance and support.

3. Necessity of Retractable Injection Quills:

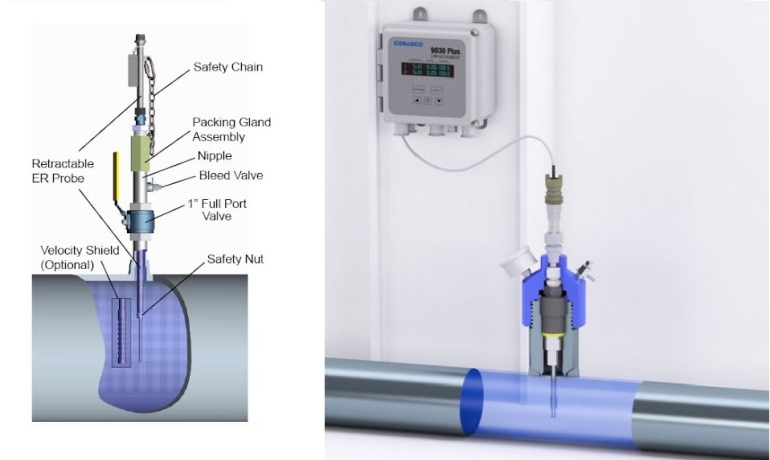

Retractable Injection Quills are essential for the effective maintenance and functioning of industrial piping systems. They play a critical role by injecting chemicals precisely into the pipeline’s center, promoting the efficient mixing of chemicals with the process fluid—a crucial aspect for the efficacy of the treatments applied.

- Precise Chemical Delivery: They enable accurate placement of chemicals, minimizing risks associated with dosing inaccuracies.

- Protection of Piping Walls: The central injection approach safeguards pipe walls from concentrated chemical contact, averting corrosion or degradation.

- Enhanced Safety: The retractability feature allows for maintenance and inspection without system shutdowns or process interruptions, improving safety protocols.

- Versatility: Suitable for various applications, the quills are compatible with an array of chemicals and conditions due to their material diversity and temperature range.

- Maintenance Efficiency: Easy removal for cleaning or replacement streamlines maintenance procedures and trims downtime.

4. Application of Retractable Injection Quills:

- Corrosion Inhibition: For pipelines transporting corrosive fluids, quills administer corrosion inhibitors to preserve the pipeline material.

- Scale Prevention: In water treatment, they inject scale inhibitors to prevent mineral build-ups that could impair the system.

- Biocide Addition: Biocides are introduced to curb bacterial growth that can lead to fouling and corrosion.

- pH Control: They facilitate pH adjustments by injecting acids or bases as required by the process.

- Foam Control: Anti-foaming agents dispensed via quills manage foam in specific industrial operations.

- Dispersant Injection: The quills administer dispersants to manage sludge formation and maintenance.

- Sampling: They can also serve in sampling process fluids, allowing for regular fluid characteristic assessments.

In conclusion, retractable injection quills are crucial for the adept, secure, and accurate management of chemicals within industrial piping systems. They ensure the integrity of the pipeline, maintain process fluid quality, and enhance the operational efficiency of industrial processes.

Il n’y a pas encore d’avis.