Selection Model of Corrosion Coupon In Piping

| Modèle | |||||||||||||

| CC | Corrosion Coupons | ||||||||||||

| -Code | Assemblage du corps de la prise | ||||||||||||

| Pxxx | Type | Matériel | Scellement Matériel | ||||||||||

| 0 | Aucune demande | 0 | CS | 0 | Aucune demande | ||||||||

| 1 | Creux Corps de la prise | 1 | 316SS | 1 | Joint torique Viton / Garniture primaire en PTFE | ||||||||

| 2 | Corps de prise solide | 2 | 316LSS | 2 | HNBR | ||||||||

| 3 | DUPLEX SS | ||||||||||||

| 4 | INCONEL | ||||||||||||

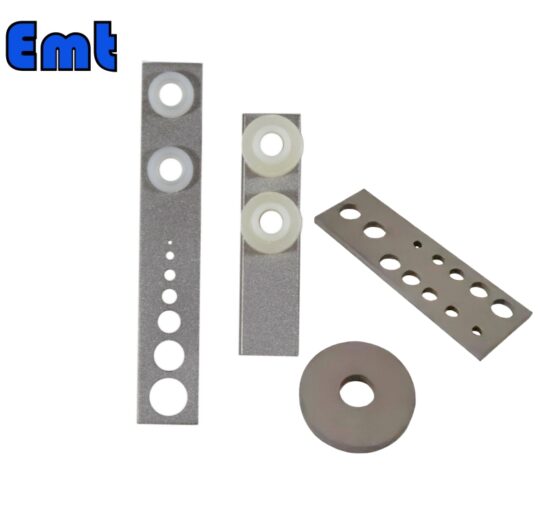

| Type de Détenteur du coupon | |||||||||||||

| SR | Fixe Détenteur du coupon pour l’assemblage de coupon | ||||||||||||

| AR | Réglable Détenteur du coupon pour l’assemblage de coupon | ||||||||||||

| LR | Porte-coupon d’échelle pour l’assemblage de coupons rectangulaires | ||||||||||||

| SC | Fixe Détenteur du coupon pour l’assemblage circulaire coupon | ||||||||||||

| Courant alternatif | Réglable Détenteur du coupon pour l’assemblage circulaire coupon | ||||||||||||

| -Taille du tuyau | |||||||||||||

| x | Taille du tuyau en pouce | ||||||||||||

| – Coupon Taille | |||||||||||||

| A×B×C | Coupon Taille en pouce ou mm | ||||||||||||

| – Matériel du coupon | |||||||||||||

| x | Grade | ||||||||||||

| -Finition de Coupon | |||||||||||||

| 0 | Moulin | ||||||||||||

| 1 | Perle de verre | ||||||||||||

| – Joint d’isolation | |||||||||||||

| 0 | Pas de joint d’étanchéité | ||||||||||||

| 1 | Joint en nylon | ||||||||||||

| 2 | Joint FTFE | ||||||||||||

| Par exemple CC-P221-SR-6 »-3"×1/2"×1/8 »-MS1018-0-2 CC : Coupon de corrosion | |||||||||||||

| P221 : Corps de connecteur solide en joint torique Viton 316LSS et garniture primaire en PTFE | |||||||||||||

| SR-6 » :Porte-coupon fixe pour l’assemblage de coupons rectangulaires et pour tuyau de 6 » | |||||||||||||

| 3"×1/2"×1/8 » : Coupon Taille MS1018 : Matériel du coupon | |||||||||||||

| 0: Finition de Le coupon est Mill 2 : Le matériau du joint d’isolation est en PTFE | |||||||||||||

Different Corrosion Types

Corrosion in pipelines creates significant challenges. Understanding different types helps manage these effectively.

Uniform corrosion affects surfaces evenly. This leads to consistent material loss, making it predictable and manageable with coatings.

Pitting corrosion forms small pits in the metal. These can penetrate deeply, often causing leaks, especially in moist environments.

Crevice corrosion occurs in confined spaces. It thrives in gaps with limited oxygen, commonly found in flanges and gaskets.

Galvanic corrosion arises when dissimilar metals contact each other. One corrodes faster, requiring an electrolyte like water.

Erosion corrosion combines wear and chemical attack. High-velocity fluids intensify this, often in bends and elbows.

Microbial-induced corrosion results from bacterial activity. These microbes produce acids that degrade metal, affecting water or oil pipelines.

Stress corrosion cracking involves tensile stress and a corrosive environment. Cracks form over time, leading to sudden failures.

Intergranular corrosion occurs along grain boundaries. It weakens the structure, causing fractures, sometimes preventable with heat treatments.

Hydrogen-induced cracking happens from hydrogen atoms in the metal. This reduces ductility, impacting pipelines with hydrogen-rich fluids.

Effective prevention strategies are essential. Regular inspections and maintenance reduce corrosion impact. Choosing appropriate materials enhances pipeline longevity. Coatings, inhibitors, and cathodic protection offer additional safeguards. Understanding these types allows for targeted solutions, ensuring pipeline integrity and safety.

Steps of Using Corrosion Coupon In Piping

To use a corrosion coupon effectively, follow these steps:

First, select the right coupon material for your pipeline. Consider the environment and corrosion type. Please thoroughly read and understand the coupon terms and conditions before using in order to ensure accurate results. Use a suitable solvent to remove any contaminants.

Next, weigh the coupon precisely and record its initial weight. Install the coupon in a designated holder within the pipeline. Ensure it faces the fluid flow for accurate exposure. Secure the holder to prevent movement during operation.

Monitor the coupon over a specified period, usually several months. After ensuring the pipeline is clear and the area is safe, carefully lift the coupon from the pipeline using the provided equipment. Clean it again to eliminate any deposits. Weigh the coupon again and record the final weight.

Calculate the weight loss to determine the corrosion rate. Analyze this data to assess the pipeline’s condition. The use of the provided information enables the maintenance and repair decisions to be made with greater certainty, as it provides specific facts and details about the workings of the machine or system. Regularly repeat this process for continuous monitoring.

Corrosion coupons provide valuable insights into corrosion rates and types. They help in implementing preventive maintenance strategies. Early detection of corrosion minimizes potential failures. This systematic approach ensures pipeline integrity and safety.

Spécifications

| Matériel | Acier inoxydable 304, acier inoxydable 316, DSS F51, acier au carbone A105N, Inconel 625 |

| Température de fonctionnement | -20±120 |

| Caractéristique | Tout d’abord, facile à utiliser |

| Deuxièmement, haute précision et longue durée de vie | |

| Enfin, haute efficacité, faible coût | |

| Paiement | TT/LC |

| Avantage | Tout d’abord, ils sont légers et flexibles. |

| Deuxièmement, une belle efficacité d’injection. | |

| Enfin, un suivi précis de la localisation. |

Importance of Corrosion Coupon In Piping

First, corrosion coupons offer a simple and cost-effective monitoring method. They require minimal equipment and are easy to use. By installing them in various locations, operators can pinpoint specific corrosion issues.

Additionally, corrosion coupons help identify different corrosion types. This data guides targeted prevention strategies. Operators can adjust maintenance plans based on real-time information.

Furthermore, regular monitoring with coupons ensures early detection of corrosion. Early intervention minimizes potential pipeline failures. This proactive approach enhances safety and extends pipeline lifespan.

Corrosion coupons also complement other inspection techniques. They provide tangible evidence of material degradation. Combining data from multiple sources improves overall corrosion management.

Finally, using corrosion coupons supports regulatory compliance. Many industries require regular corrosion monitoring. Coupons help meet these standards efficiently.

In summary, corrosion coupons are essential for effective pipeline management. They offer valuable insights into corrosion processes. This knowledge ensures pipeline integrity and operational safety.

Il n’y a pas encore d’avis.