Nom | Sonde de corrosion haute pression EMT Sonde à résistance électrique | ||||

Matériel | Acier inoxydable 316、L DUPLEX SS | ||||

Température de fonctionnement | -20 ~ 200 °C | ||||

Caractéristique | 1. Utilisation facile | ||||

2. Haute précision Longue durée de vie | |||||

3. Haute efficacité, faible coût | |||||

Paiement | TT/LC | ||||

Avantage | 1. Ils sont légers et flexibles. | ||||

2. Belle efficacité d’injection. | |||||

3. Suivi précis de la localisation. | |||||

Matériau métal : 316、L DUPLEX SS

Matériau d’étanchéité : Téflon/ Caoutchouc fluoré

Température de fonctionnement : -20 ~ 200 °C

Pression de travail : 0 ~ 26MPa

Accès corps de raccord et couvercle de protection :

Taille de la bride : ANSI 2" RF (ou RJ)

Matériau : CS 、316L、 DUPLEX SS

Pression de travail : 0 ~ 26MPa

Température de fonctionnement : -20 ~ 200 °C

Introduction

La corrosion est une menace omniprésente pour les équipements et les infrastructures industrielles, capable de causer des dommages matériels et économiques importants. Pour gérer efficacement ce risque, l’industrie utilise diverses techniques de surveillance, parmi lesquelles la technique de la résistance électrique (RE) se distingue par sa polyvalence et ses capacités de surveillance en temps réel. La sonde de corrosion EMT (Electrical Resistance Monitoring Tool) exploite la méthode ER pour fournir une solution complète pour un large éventail d’environnements où la corrosion est une préoccupation.

La technique de la résistance électrique (ER)

La technique ER est une méthode sophistiquée de surveillance de la corrosion en ligne. Il mesure l’augmentation de la résistance électrique d’un élément métallique lorsqu’il se corrode, ce qui est directement lié à la perte de métal et, par conséquent, à la vitesse de corrosion. Cette technique tient compte à la fois des réactions électrochimiques et des effets mécaniques tels que l’érosion, ce qui en fait un outil complet pour évaluer la santé des structures métalliques.

La sonde de corrosion EMT

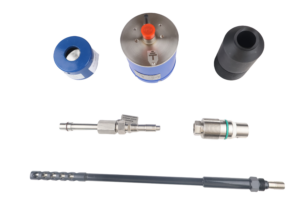

La sonde de corrosion EMT est un instrument de pointe conçu pour mettre en œuvre la technique RE sur le terrain. Il est composé de deux composantes principales :

1.L’instrument :

Il peut s’agir d’un appareil permanent pour la surveillance continue ou d’une unité portable pour les évaluations périodiques. Il est chargé de mesurer et d’enregistrer les changements de résistance au fil du temps, qui sont indicatifs des taux de corrosion.

2. La sonde :

La sonde est la partie du système qui est exposée à l’environnement corrosif. Il contient un élément de détection fabriqué à partir d’un matériau identique ou similaire à celui de l’équipement surveillé. Cela permet de s’assurer que le taux de corrosion mesuré par l’EMT est représentatif des conditions réelles affectant l’infrastructure.

Avantages de la sonde de corrosion EMT

L’EMT offre plusieurs avantages aux industries qui cherchent à protéger leurs actifs contre la corrosion :

1. Surveillance en temps réel :

Offre des informations en ligne et continues sur les taux de corrosion, ce qui permet d’intervenir en temps opportun.

2. Polyvalence :

Convient à une variété d’environnements, y compris ceux avec de faibles électrolytes tels que les gaz et les liquides non aqueux.

3. Sondes personnalisables :

Les éléments de détection peuvent être adaptés aux matériaux de l’infrastructure surveillée, ce qui permet d’obtenir des données plus précises et plus pertinentes.

4. Maintenance préventive :

Les données de l’EMT peuvent éclairer les calendriers de maintenance, prévenir les défaillances catastrophiques et prolonger la durée de vie de l’équipement.

Applications

En raison de son adaptabilité, la sonde de corrosion EMT est idéale pour un large éventail d’applications. Voici quelques-unes des industries et structures clés où l’EMT peut être particulièrement bénéfique :

1. Pétrole et gaz :

Pour la surveillance des systèmes de production et de transport, où la prévention des fuites et l’intégrité des pipelines sont essentielles.

2. Usines pétrochimiques :

Dans les flux de processus où la corrosion peut entraîner des inefficacités ou des conditions dangereuses.

3. Infrastructure :

Sur les surfaces externes des canalisations enterrées et dans les systèmes d’eau d’alimentation où la corrosion peut passer inaperçue jusqu’à la défaillance.

4. Contrôle de l’environnement :

Dans les cheminées de gaz de combustion et autres systèmes de contrôle des émissions où la corrosion peut entraver les performances.

Architecture : Pour l’entretien des éléments métalliques dans les bâtiments et les structures, assurant la longévité et la qualité esthétique.

Conclusion

La sonde de corrosion EMT représente une avancée significative dans la technologie de surveillance de la corrosion. En fournissant un système précis, en ligne et polyvalent, l’EMT garantit que les industries peuvent gérer efficacement le défi persistant de la corrosion, protégeant ainsi les actifs, l’environnement et la vie humaine.

Coupons pour Sondes anticorrosion Vs Corrosion

Les sondes de corrosion et les coupons de corrosion sont tous deux des outils utilisés pour surveiller les taux de corrosion dans divers systèmes industriels, mais ils fonctionnent sur des principes différents et offrent des avantages et des inconvénients distincts.

Corrosion Coupons:

Un coupon de corrosion est un petit morceau de métal normalisé qui correspond à la composition du matériau du système qu’il surveillera. Vous l’installez directement dans le flux du flux de processus, et il y reste pendant une période déterminée. Après l’enlèvement, le coupon est nettoyé et analysé pour déterminer la quantité de corrosion qui s’est produite, généralement en mesurant la perte de poids. Cette méthode fournit un moyen direct et tangible de mesurer les pertes de métal dues à la corrosion au fil du temps.

- Avantages des coupons anticorrosion :

Méthode simple et peu coûteuse.

Mesure directe des pertes métalliques.

Fournit une indication visuelle du type et de la gravité de la corrosion.

- Inconvénients des coupons Corrosion :

Fournit des données sur les taux de corrosion uniquement sur la période d’exposition, et non en temps réel.

Nécessite l’arrêt du système pour le retrait et l’installation.

L’analyse peut prendre du temps et être retardée.

Sondes de corrosion :

Les sondes de corrosion sont des appareils plus sophistiqués qui permettent de surveiller en temps réel les taux de corrosion. Ces sondes peuvent être installées de manière permanente dans un système et connectées à un compteur qui enregistre les taux de corrosion en continu. Ils fonctionnent en mesurant des paramètres électriques en corrélation avec l’activité de corrosion, tels que le bruit électrochimique, la résistance à la polarisation linéaire ou la résistance électrique.

- Avantages des sondes de corrosion :

Suivi en temps réel des taux de corrosion.

Pas besoin d’arrêter le système pour la collecte des données.

Peut fournir un retour d’information immédiat pour les ajustements de processus.

- Inconvénients des sondes de corrosion :

Plus complexe et plus coûteux que les coupons anticorrosion.

Nécessite un étalonnage et peut être sensible aux changements des conditions du processus.

L’interprétation des données peut nécessiter des connaissances spécialisées.

Il n’y a pas encore d’avis.