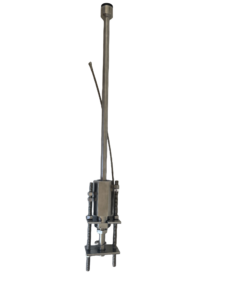

Brief Introduction of EMT Corrosion Probes

EMT Corrosion Probes can be used in many environmental conditions. The continuous change of the resistance value of the probe determines the metal loss. Our corrosion probes’ sensitive element forms include ring type, tube type, ring tube type, flat head type, and strip type. The main material is 316 stainless steel, and the material of the sensitive element can be customized to suit different monitoring environments.

Materials Introduction

EMT Corrosion Probes consist of tough materials fit for tough jobs. Stainless steel forms the probe’s main body, resisting corrosion and heat like a champ. This makes it a top pick for extreme conditions. Carbon steel, strong and reliable, makes up the probe’s cover. Yet, to make it not rust, we coat it with PTFE.

PTFE, also known as Teflon, is a plastic with superpowers. It laughs in the face of heat and harsh chemicals and doesn’t conduct electricity. This coating gives the carbon steel cover a superhero shield against damage.

Now, the flange is the probe’s muscle, adding strength. It can be either stainless steel or carbon steel, depending on what the job demands. Stainless steel steps in when the going gets tough, withstanding corrosive and hot environments. Carbon steel might come into play in milder settings, especially when it gets a boost from a PTFE coat.

Choosing the right material matters a lot. You’ve got to consider the conditions, the job, and the substances the probe will meet. Stainless steel usually wins for its anti-rust and anti-heat qualities. But if the environment is less demanding, carbon steel with a PTFE coat will do just fine.

Flexibility is key with EMT. They can switch up materials to meet customer needs, customizing probes for any situation. This adaptability ensures EMT Corrosion Probes can tackle various industry challenges.

Main Parameters of EMT Corrosion Probes

- Matériau métallique : 316、L DUPLEX SS

- Sealing Material: Teflon or Fluororubber

- Température de fonctionnement : -20 ~ 200 °C

- Working Pressure: 0~26 MPa

- Access Fitting Body and Protective Cover:

- Size of Flange: ANSI 2″ RF (or RJ)

- Material: CS, 316L, DUPLEX SS

- Working Pressure: 0~26 MPa

- Température de fonctionnement : -20 ~ 200 °C

Nom | EMT-ER Corrosion Probe | |

| Matériel | Acier inoxydable 316、L DUPLEX SS | |

| Température de fonctionnement | -20 ~ 200 °C | |

| Fonctionnalités | Tout d’abord, il est facile à utiliser | |

| Deuxièmement, haute précision et longue durée de vie | ||

| At last, high-efficiency Low cost | ||

| Paiement | TT/LC | |

| Avantages | Tout d’abord, ils sont légers et flexibles. | |

| Et puis belle efficacité d’injection. | ||

| Enfin un suivi précis de la localisation. |

Compete with Online Corrosion Monitoring Remote Data Collection

The EMT-CP-0 system excels in online corrosion monitoring by measuring resistance changes in the probe’s sensitive elements to track corrosion thinning. Essentially, it calculates the sensitive elements’ corrosion rate, reflecting the pipeline or equipment’s wear when materials match. Over time, this accumulation pinpoints the corrosion pace. Notably, the collector boasts an explosion-proof seal, perfect for the petrochemical industry’s demanding environments. Thus, it enables real-time monitoring, safeguarding vital infrastructure from corrosion’s subtle yet relentless advance.

Principaux paramètres de performance

Plage : 0 ~ 261144 unités de durée de vie de la sonde ;

Plage d’impédance de l’élément sensible à la sonde : 1 ~ 50 mΩ.

Resolution: Typical value 1nm; (The total thickness of a typical probe-sensitive element is 20mil, with a lifespan of 10mil.)

Repeatability: ±?% of full scale;

Alimentation : alimentation 24VDC / batterie au lithium ;

Consommation de courant : 12mA@24VDC/1~12mA@8.4V ;

Communications : RS485 à deux fils, débit de 2400 bauds/2,4G, LORA, 4G/5G ou 4-20 mA

Adresse RS485 : 0 ~ 31

Température ambiante : -40°C~ +70°C

Niveau de protection du boîtier : IP 65

Taux de collecte maximum : Une fois par minute

Taux de collecte minimum : Une fois à n’importe quel intervalle

Certification des zones dangereuses : Ex d IICT4 Gb

Applications des sondes de corrosion

Corrosion probes serve a variety of applications across different industries by monitoring and measuring the rate of material degradation due to corrosion. Here are some of their key applications:

- Pétrole et gaz: Corrosion probes are critical in monitoring the integrity of pipelines, tanks, and other equipment used in the extraction, transportation, and processing of oil and gas.

- Chemical Manufacturing: They help ensure the safety and longevity of reactors, vessels, and piping that handle corrosive substances.

- Power Generation: Corrosion probes monitor the condition of boilers, cooling systems, and water-steam circuits in power plants.

- Traitement de l’eau: They are used in water and wastewater treatment facilities to track corrosion in pipes and storage tanks.

- Marine: Probes monitor corrosion in ship hulls, ballast tanks, and offshore structures, which are constantly exposed to corrosive marine environments.

- Infrastructure: Bridges, tunnels, and other structures benefit from corrosion monitoring to prevent structural failures.

- Automotive and Aerospace: They are used to test corrosion in vehicles and aircraft under varying environmental conditions.

- Produits pharmaceutiques: In pharmaceutical manufacturing, probes ensure that vessels and pipes remain free from corrosion that could contaminate products.

By using corrosion probes, these industries can plan maintenance, predict equipment failures, and extend the life of their assets, ultimately saving money and ensuring safety.

Conclusion

In conclusion, EMT Corrosion Probes deliver reliability. They offer precise, real-time corrosion monitoring. Industries trust them for safety and maintenance planning. Their robust design ensures durability. This technology represents a smart investment. It’s essential for modern industry health.

Il n’y a pas encore d’avis.