Meet the EMT ECP Series ER Probe Assembly, the cutting-edge tool for keeping an eye on corrosion in real-time. Designed to tackle the harsh realities of industrial settings, this probe is your go-to for checking how equipment pipelines stand up against corrosion. It’s like having a health monitor for your machinery – the probe spots resistance changes as they happen, giving you the lowdown on the state of your pipes pronto. It’s all about catching those sneaky corrosion issues early, so you can nip them in the bud before they turn into full-blown safety nightmares.

Parameters Table

Nom | EMT High Pressure Corrosion Probe Electrical Resistance Probe Corrosion Monitoring | ||||

Matériel | Acier inoxydable 316、L DUPLEX SS | ||||

Température de fonctionnement | -20 ~ 200 °C | ||||

Caractéristique | 1. Utilisation facile | ||||

2. Haute précision Longue durée de vie | |||||

3. Haute efficacité, faible coût | |||||

Paiement | TT/LC | ||||

Avantage | 1. Ils sont légers et flexibles. | ||||

2. Belle efficacité d’injection. | |||||

3. Suivi précis de la localisation. | |||||

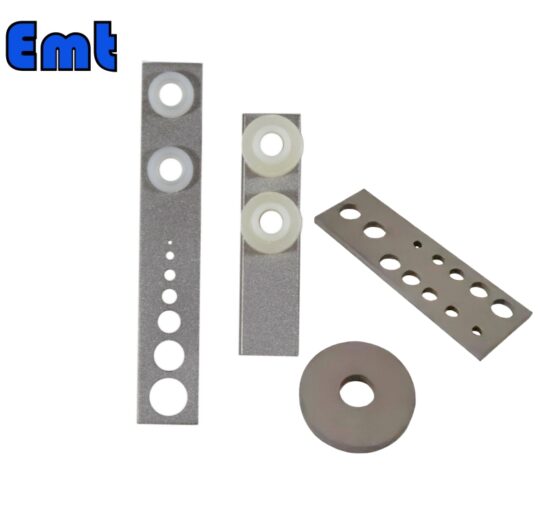

Meticulously engineering the assembly, comprising several key components: an installation body, a resilient protective cover, the resistance probe itself, a hollow plug body, and an integrated temperature and pressure gauge. Such a comprehensive setup ensures both protection and functionality.

As for the probe variants, they are available in two forms: the cylindrical resistance probe and the sheet resistance probe. Each type is suited for different applications, offering flexibility in monitoring.

1.Installation

Installation is versatile; depending on the specific requirements, the installation body can be affixed via welding or flange—options that accommodate a range of operational contexts. Whether it’s a Welding Base or Flange Base, the installation process is straightforward, enhancing adaptability and ease of use.

2.Technical specification

Focusing on the technical specifications, the internal components boast robust construction. Metal materials like 316L and F51 duplex stainless steel provide durability, while sealing materials such as Teflon or fluororubber ensure a tight and reliable seal. The probes operate effectively within a wide temperature range of -20 to 200 °C and can withstand pressures up to 26MPa.

3.Assembly

The main body and protective cover of the probe are equally remarkable. Adhering to ANSI 2″ RF (or RJ) standards, the flange size offers material options that include CS, 316L, and duplex stainless steel. Moreover, these components are designed to manage the same pressure and temperature ranges as the internal components, which ensures uniformity and dependability across the entire assembly.

In summation, the EMT ECP Series Resistance Probe Assembly stands as a testament to precision engineering and versatility. It serves as a critical tool for upholding the safety and extending the life of industrial equipment, thereby reaffirming EMT’s dedication to innovation and excellence in the realm of corrosion monitoring technology.

EMT ER Probe

A state-of-the-art instrument engineered for the meticulous task of corrosion monitoring. This probe stands out for its ability to deliver real-time insights into the corrosive conditions within your industrial systems. By actively detecting variations in electrical resistance, it offers a clear picture of the corrosion status, ensuring that you’re always a step ahead in maintaining the integrity of your pipelines.

Equipped with a robust installation assembly, the EMT ER Probe includes a durable installation body, a protective cover to withstand harsh conditions, a precise resistance probe, a hollow plug body, and a combined temperature and pressure gauge component. This comprehensive configuration is designed to function seamlessly, providing reliable data with exceptional accuracy.

Transitioning to the probe’s design, we find two distinct types

Two distinct types:

the cylindrical and the sheet resistance probes, each tailored for specific monitoring scenarios. The cylindrical probe excels in general-purpose applications, while the sheet resistance probe is ideal for areas requiring a larger surface contact.

Moreover, the installation process is highly adaptable. We can secure the probe in place either by welding or by using a flange connection, depending on what the particular situation demands. This flexibility ensures that the probe can be integrated into a variety of pipeline systems with relative ease.

Delving into the technical aspects, the internal components are crafted from high-quality materials such as 316L and F51 duplex stainless steel, promising longevity and resistance to corrosion. Sealing materials like Teflon and fluororubber are selected for their reliability and ability to maintain a seal in a range of conditions, with operational temperatures spanning from -20 to 200 °C and pressures up to 26MPa.

In conclusion, the EMT ER Probe represents the pinnacle of corrosion monitoring technology. Its sophisticated design, combined with versatile installation options and durable materials. Which make it an indispensable ally for safeguarding the health of your industrial pipelines and equipment.

Notre service

1.Many kinds of coupon de corrosion and probe with different type to meet difference requirements.

2. Des échantillons seront proposés pour attester de la qualité et de nos services.

3. Le retour d’information le plus rapide !

4. Le délai de livraison le plus rapide.

5,24 heures, 7 jours en ligne.

Il n’y a pas encore d’avis.