Introduction to Injection Quill in Piping

Introduction to Injection Quill in Piping

Injection quills play a crucial role in modern industry by ensuring precise chemical dosing into pipelines. These devices facilitate the uniform distribution of chemicals, preventing local concentrations that could corrode or damage the system. Typically, industries use them to inject additives that enhance process efficiency or protect the integrity of the fluid transport system.

Overview of Injection Quill Usage in Various Industries

Various industries rely heavily on injection quills for their operations. In the oil and gas sector, they prevent corrosion and scaling inside pipelines. Water treatment facilities use them to add disinfectants and other treatment chemicals efficiently. Pharmaceutical companies also utilize injection quills to maintain the purity and exact composition of their products. This wide-ranging applicability underscores their importance across sectors.

Importance of Injection Quills in Piping Systems

Injection quills are vital for maintaining the longevity and efficiency of piping systems. They ensure that chemicals mix thoroughly with the process stream before they reach critical components, reducing wear and tear. Moreover, their ability to deliver precise chemical doses minimizes waste and enhances the overall safety of the system. By safeguarding against chemical imbalances, injection quills contribute significantly to operational stability and safety.

Modèle de sélection

| Modèle | ||||||||||||||||||||||||||||

| SI | Plume d’injecteur chimique | |||||||||||||||||||||||||||

| -Code | Bouchon | |||||||||||||||||||||||||||

| Pxxx | Type | Matériel | Scellement Matériel | |||||||||||||||||||||||||

| 0 | Aucune demande | 0 | CS | 0 | Aucune demande | |||||||||||||||||||||||

| 1 | Creux Corps de la prise | 1 | 316SS | 3 | DSS | 1 | Joint torique Viton / Garniture primaire en PTFE | |||||||||||||||||||||

| 2 | Corps de prise solide | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| –Code | Écrou d’injection | |||||||||||||||||||||||||||

| Nxx | Taille de la connexion | Matériel | ||||||||||||||||||||||||||

| 0 | c’est-à-dire aucune demande | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | c’est-à-dire 1/4" | 1 | c’est-à-dire 316SS | 3 | c’est-à-dire le DSS | |||||||||||||||||||||||

| 2 | c’est-à-dire 1/2" | 2 | c’est-à-dire 316LSS | 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||

| –Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx" | Taille de la connexion | Matériel | Buse | Taille de ligne (x") | ||||||||||||||||||||||||

| 0 | Aucune demande | 0 | CS | 0 | c’est-à-dire aucune demande | La position la plus efficace pour l’injection se situe généralement au centre du tuyau | ||||||||||||||||||||||

| 1 | c’est-à-dire 1/4" | 1 | c’est-à-dire 316SS | 1 | c’est-à-dire ouvert | |||||||||||||||||||||||

| 2 | c’est-à-dire 1/2" | 2 | c’est-à-dire 316LSS | 2 | c’est-à-dire Quill | |||||||||||||||||||||||

| 3 | c’est-à-dire le DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||||||

| –Code | Mamelon et valve (ou extrémité bride) du té | |||||||||||||||||||||||||||

| Txx | Taille de la connexion | Matériel | ||||||||||||||||||||||||||

| 0 | c’est-à-dire aucune demande | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | c’est-à-dire mamelon de 1/4 po | un | c’est-à-dire mamelon et valve de 1/4 po | 1 | c’est-à-dire 316SS | |||||||||||||||||||||||

| 2 | c’est-à-dire mamelon de 1/2 po | b | c’est-à-dire mamelon et valve de 1/2 po | 2 | c’est-à-dire 316LSS | |||||||||||||||||||||||

| 3 | c’est-à-dire mamelon 3/4" | c | c’est-à-dire mamelon et valve 3/4" | 3 | c’est-à-dire D SS | |||||||||||||||||||||||

| 4 | c’est-à-dire 1" Mamelon | d | c’est-à-dire mamelon et valve de 1 po | 4 | c’est-à-dire INCONEL | |||||||||||||||||||||||

| 5 | c’est-à-dire bride 1/4" | e | c’est-à-dire 1/4" Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 6 | c’est-à-dire 1/2" Bride | f | c’est-à-dire 1/2 "Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 7 | c’est-à-dire bride 3/4" | g | c’est-à-dire 3/4 "Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| 8 | c’est-à-dire bride de 1 " | h | c’est-à-dire 1" Bride d’extrémité de mamelon | |||||||||||||||||||||||||

| Par exemple, SI-P221-N12-S122-L4"-T22 | ||||||||||||||||||||||||||||

| SI:e.g. Sampling & Injection Assembly, | ||||||||||||||||||||||||||||

| P221 : par exemple corps de connecteur solide en joint torique Viton 316LSS et garniture primaire en PTFE, | ||||||||||||||||||||||||||||

| N12 : par exemple, la taille de la connexion de l’écrou d’injection est de 1/4 "et Le matériau est 316LSS, | ||||||||||||||||||||||||||||

| S122 :p. ex. injection Tube La taille de la connexion est de 1/4" et Le matériau est 316LSS. Le type de buse est des piquants | ||||||||||||||||||||||||||||

| L4 » :Pour tuyau de 4 ». | ||||||||||||||||||||||||||||

| T22 : Mamelon de la taille de la connexion en T est de 1/2", Le matériau de l’écrou est 316LSS | ||||||||||||||||||||||||||||

Understanding Injection Quills in Piping

What is an Injection Quill?

Definition and Basic Function

An injection quill is a device designed to safely and efficiently introduce chemicals into a pipeline. It ensures that chemicals disperse evenly within the flow of the fluid, preventing localized concentrations that could damage the system or degrade the process quality.

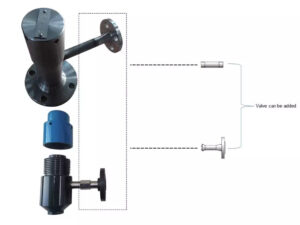

Components of an Injection Quill

Typically, an injection quill consists of a body, a check valve to prevent backflow, a nozzle for dispersing chemicals, and a connection port. These components work together to facilitate the smooth injection of chemicals into a pipeline.

How Injection Quills Work

Process of Injecting Chemicals into a Pipeline

Injection quills extend into the pipeline, allowing chemicals to enter the stream away from the pipe walls. This placement ensures thorough mixing and prevents the chemicals from concentrating in one area, which could lead to pipe damage or inefficient chemical use.

Role in Maintaining Fluid Flow and Pressure

By design, injection quills also help maintain consistent fluid flow and pressure within the pipeline. They introduce chemicals without disrupting the flow or causing pressure drops, which is crucial for maintaining the efficiency and safety of the pipeline operation. This feature is particularly important in high-pressure environments common in many industrial applications.

Spécifications

| Nom | Plume d’injection dans la tuyauterie |

| Matériel | Stainless Steel 304, Stainless Steel 316、DSS F51、Carbon Steel A105N、Inconel 625 |

| Température de fonctionnement | -20±120 |

| Caractéristique | 1. Utilisation facile |

| 2. Haute précision, longue durée de vie | |

| 3. Haute efficacité, faible coût | |

| Paiement | TT/LC |

| Avantage | Tout d’abord, ils sont légers et flexibles. |

| Deuxièmement, une belle efficacité d’injection. | |

| Enfin un suivi précis de la localisation. |

Applications of Injection Quills

Injection quills serve as integral components in various industries, optimizing the delivery and effectiveness of chemical treatments within piping systems.

Industries that Utilize Injection Quills

Pétrole et gaz

In the oil and gas industry, operators use injection quills to inject corrosion inhibitors directly into pipelines. This practice helps maintain pipeline integrity and prolongs their operational life, which is crucial for preventing costly downtime and accidents.

Traitement de l’eau

Water treatment plants rely on injection quills to add chlorine and other disinfectants safely. These quills ensure that chemicals disperse evenly, effectively neutralizing pathogens and ensuring water safety for communities.

Pharmaceutical Manufacturing

Pharmaceutical manufacturers use injection quills to introduce precise amounts of chemicals into their processes. This precision is essential for maintaining strict quality control and ensuring the efficacy and safety of pharmaceutical products.

Common Uses in Each Industry

Preventing Corrosion

Injection quills allow for the controlled release of corrosion inhibitors across industries, protecting vital components from chemical and oxidative damage.

Controlling Microbial Growth

In sectors like water treatment and pharmaceuticals, injection quills help manage microbial growth, ensuring compliance with health regulations and maintaining product integrity.

Facilitating Precise Chemical Dosing

Precision in chemical dosing is crucial across all sectors when using injection quills. Accurate dosing improves process efficiency, reduces waste, and minimizes environmental impact.

Il n’y a pas encore d’avis.