Introduction to Indicateur de passage des racleurs

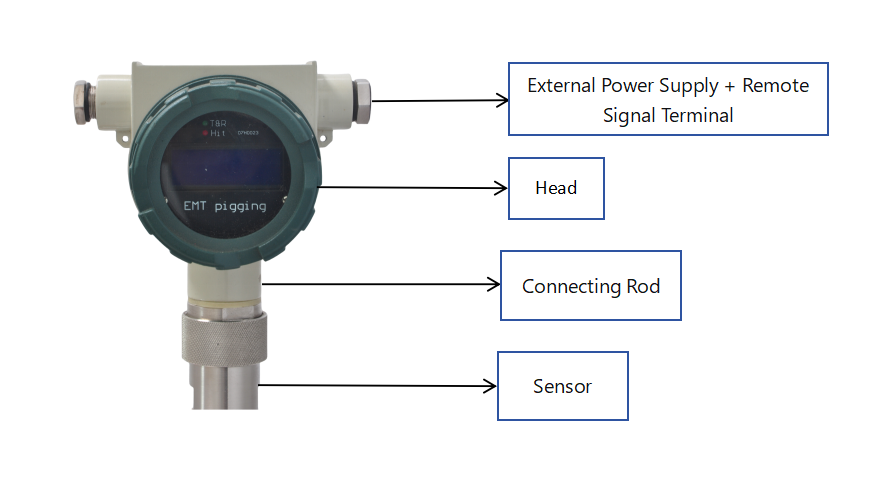

The Pig Passage Indicator is an important tool to monitor and manage the pipeline maintenance process. As a two-way intrusion device, it can be attached to a pipe via a welded base or flange and is capable of withstanding pressures up to ANSI 2,500 (6,170 psi). The device has a trigger that can be minimally extended into the pipe, ensuring contact with a passing pig or sphere while having a negligible impact on fluid flow. Any pipe diameter can be customized to specific requirements, and the trigger length can be adjusted on-site to accommodate different pipe thicknesses. When the pig or ball comes into contact with the trigger, the indicator is activated to signal the channel via a mechanically operated signal marker, an electronic automatic reset switch, or both. This feature ensures reliable, real-time monitoring of pig movement in the pipeline, which is critical to operational efficiency and safety.

Types of EMT Pig Passage Indicators

Specifications of Pig Passage Indicator

| Nom | Indicateur de passage des racleurs |

| Connexion | Raccord à bride |

| Longueur du corps de la prise | 200 millimètres |

| Température de fonctionnement | -20 ~ 120 °C / Répondre aux exigences du client |

| NACE MR 01-75 | Oui |

| Protection contre les infiltrations | IP65/IP66 |

| Classe antidéflagrante | ExdII. BT4 |

| Retirer sous pression | Non |

| Type de déclencheur | Bidirectionnel/Unidirectionnel |

| Longueur ajustable | 20 millimètres |

| Matériau de la pièce interne | 316SS/DSS/INCONEL |

| Profondeur de l’insert | 21 mm (Bi)/13 mm (Uni) |

| Matériau de la bride/du corps | Revêtement PTFE A105N / 304SS / 316SS / DSS / INCONEL(Selon MR) |

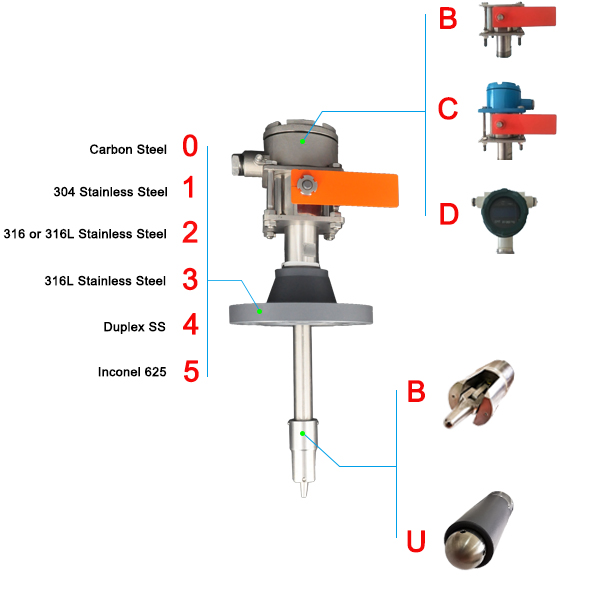

Trigger Types

| Types d’indicateurs | Un | B | C | D |

| Type intrusif | Intrusif | Intrusif | Intrusif | Non intrusif |

| Caractéristiques de l’indicateur | Type de bouton-pression | Drapeau de réinitialisation manuelle | Drapeau de réinitialisation manuelle combiné à des signaux électriques | Affichage de la date et de l’heure combiné à des signaux électriques |

Options Available

Options Available: Custom Seal extensions can be attached to enable detection of the pig’s passage on buried pipelines.

All pressure-sealing components remain below the extension module.

Available in lengths 2′ to 8′.

Flange Mount models are designed to connect to existing flanged connections and are available in ANSI Class 150, 300, 600, or 900/1500 flanges.

Conversion kits are also available, which enable installation onto the mountings of other manufacturers.

Material and Design Considerations

When selecting materials for Pig Passage Indicators, manufacturers often choose stainless steel or carbon steel. These materials offer durability and corrosion resistance, critical in harsh pipeline environments. High-density polyethylene also features prominently, especially for its resilience and flexibility. Designers focus on robust construction to withstand pressures up to ANSI 2500. This ensures that devices can handle up to 6170 psi, a common requirement in high-pressure scenarios.

For varying pipeline diameters, manufacturers provide customizable trigger lengths. They design these triggers to adjust easily on-site, which allows for seamless integration into existing pipelines. This flexibility is crucial for maintaining consistent performance across different pipeline specifications.

Applications of Pig Passage Indicators

Pig Passage Indicators find extensive use across multiple industries. The oil and gas sector, in particular, relies heavily on these devices. They also play a significant role in the petrochemical and water treatment industries. In oil and gas, operators use them primarily to ensure the efficient cleaning and inspection of pipelines. They signal the presence of a pig, helping maintain the flow and integrity of the pipeline system.

In pipeline cleaning, these indicators are indispensable. They provide real-time, accurate detection of the pig’s location, which is crucial for scheduling maintenance and avoiding costly downtime. This capability significantly enhances operational efficiency and safety. Maintenance teams can respond promptly, ensuring that pipelines remain free from blockages and operate at optimal levels.

Thus, the versatile and robust design of Pig Passage Indicators, coupled with their critical role in various industrial applications, underscores their importance in modern pipeline management. Their ability to adapt to different environments and pressures makes them a key asset in the maintenance and safety of pipeline systems across industries.

Conclusion

In summary, pig indicator is an important tool for the effective management and maintenance of the pipeline system. These devices ensure the smooth operation of the pipeline by providing critical real-time information on pig movement. As a result, the industry, particularly oil and gas, has benefited greatly from improved operational efficiency and safety standards. With models ranging from removable indicators to non-invasive indicators, solutions can be customized to meet specific operational needs and environmental conditions.

In addition, the adaptability of the pig channel indicator in terms of material selection and design customization supports its reliability under various pressures and pipe diameters. This versatility makes it indispensable in different industries, not only in the oil and gas industry but also in the petrochemical and water treatment industries. Manufacturers are constantly innovating to ensure that these metrics not only meet current needs but also adapt to future challenges.

As such, the adoption of pig channel indicators is more than just a practical option, it is a step towards optimizing pipeline integrity and efficiency, ensuring the industry keeps pace with technological advances while maintaining high safety and operating standards. This commitment to continuous improvement of pipeline management tools such as pig channel indicators underscores their critical role in the future of the industry.

Il n’y a pas encore d’avis.