Applications of Quick Opening Closure

Quick Opening Closures in the Oil and Gas Industry

Quick opening closures revolutionize pressure vessel inspection in the oil and gas sector. These devices allow workers to perform maintenance on pipelines swiftly, ensuring minimal downtime. Their design is crucial for rapid response in emergencies and for routine safety checks. High-pressure conditions are no match for the secure sealing capabilities of quick opening closures. They are instrumental during shutdowns, facilitating faster turnaround times and significantly cutting labor costs by simplifying the operation process.

The Role in Chemical Processing Plants

In chemical processing plants, quick opening closures are a safety cornerstone. They provide a reliable means to contain dangerous substances and grant operators quick access to process monitoring and sampling. The reduced downtime during product changeovers is a significant advantage. Made to withstand the harshness of chemicals, these closures ensure durability and long-term use. They are a key part of meeting safety inspection standards and help to keep maintenance schedules on track, enhancing the overall efficiency of plant operations.

Utilities and Water Treatment Facilities

At utilities and water treatment facilities, quick opening closures are essential for the maintenance of filtration systems. They allow for the rapid removal of accumulated sediment and other debris, facilitating uninterrupted service during routine inspections. In the face of urgent maintenance needs, these closures are invaluable, helping to sustain a clean water supply. Their contribution to public health is significant, as they aid in maintaining water quality standards. The corrosion-resistant materials of quick opening closures make them well-suited for the challenging environments typical of water treatment operations.

Types of Quick Opening Closure

Fermetures filetées

Threaded closures are precision-engineered to provide a secure seal through a threaded connection. The technical features include:

- Thread Profile: The threads are typically trapezoidal or square-cut to handle the axial forces and provide a leak-proof seal.

- Matériaux: Commonly constructed from carbon steel, stainless steel, or alloy materials to match the strength and corrosion resistance required by the vessel.

- Pressure Ratings: Designed to withstand a wide range of operating pressures, often suitable for both low-pressure and high-pressure applications.

- Sealing Elements: They incorporate gaskets or O-rings made from elastomers or metal seals for temperature and chemical compatibility.

- Endurance: Engineered for repeated opening and closing cycles without significant wear on the threads.

- Gamme de tailles: Generally used for small to medium-sized openings due to the manual effort required to operate larger threads.

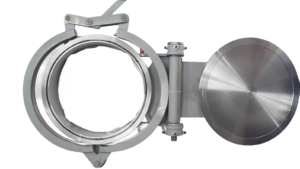

Fermetures à pince

Clamp closures are designed for quick operation, and their technical specifications include:

- Mechanism: Utilize a hinged or segmented clamp that can quickly engage with a lip on the vessel or pipe flange.

- Lever Operation: Many feature a lever that tightens the clamp, reducing manual effort and eliminating the need for tools.

- Seal Integrity: Equipped with pressure-responsive seals that ensure tightness under varying pressure conditions.

- Safety Features: Some models include safety interlocks to prevent opening under pressure.

- Construction: Made from durable materials such as stainless steel or anodized aluminum for corrosion resistance.

- Application: Ideal for frequent access points, such as sample ports or sight glasses, in chemical processing or pharmaceutical industries.

Lock Ring Closures

Lock ring closures are complex systems designed for high-performance sealing, with technical characteristics including:

- Locking Mechanism: They use a segmented or single-piece lock ring that mates with a hub on the vessel, secured by bolting or a bayonet mechanism.

- Pressure Engagement: The lock ring provides a mechanical advantage, tightening under pressure to improve the seal.

- Heavy-Duty Design: Engineered for large-diameter access points and able to handle extreme pressure and temperature fluctuations.

- Safety Mechanisms: Often equipped with pressure warning devices and interlocks to prevent opening when the vessel is pressurized.

- Facilité d’utilisation: Despite their robustness, modern designs allow for single-person operation without special tools.

- Material Compatibility: They are typically made of high-strength materials such as carbon steel or stainless steel and can be coated or lined for additional corrosion protection.

Foire aux questions (FAQ)

Can Quick Opening Closures Withstand High Pressure?

Yes, quick opening closures are engineered to withstand high pressure. They are constructed from high-strength materials and are designed with robust sealing mechanisms to maintain integrity under extreme pressure conditions. The components are tested to ensure they meet the specific pressure requirements of their intended application. The design of the closure system, including the shape and characteristics of the seal, is optimized to ensure that the closure can handle the operational pressures it will encounter in industrial environments.

What Maintenance Do Quick Opening Closures Require?

Quick opening closures require regular maintenance to ensure their safety and functionality. Maintenance activities typically include:

- Inspecting and cleaning the sealing surfaces to prevent leaks and ensure a proper seal.

- Checking the condition of gaskets or O-rings and replacing them if they show signs of wear or damage.

- Verifying the proper function of safety interlocks and pressure warning devices.

- Lubricating moving parts, such as hinges or threads, to ensure smooth operation.

- Ensuring that all closure components are free from corrosion or other damage that could compromise their performance.

- Following the manufacturer’s maintenance schedule and guidelines for periodic inspection and service.

How Do I Know If My Closure Meets Industry Standards?

How Do I Know If My Closure Meets Industry Standards?

To verify that your quick opening closure meets industry standards, you should:

- Check if the closure has certifications from recognized industry bodies, such as the American Society of Mechanical Engineers (ASME), which may indicate compliance with standards like ASME VIII for pressure vessels.

- Review documentation from the manufacturer that includes test reports, quality certificates, and compliance statements.

- Ensure the closure is used in accordance with its design specifications, including pressure ratings, temperature ranges, and material compatibility.

- Consult with the manufacturer or a qualified engineer if there are any doubts about the suitability of the closure for its intended use or its compliance with current industry regulations and standards.

Il n’y a pas encore d’avis.