Introduction

Bref aperçu des indicateurs de passage de racleur

Les indicateurs de passage de racleurs, souvent appelés détecteurs de racleurs, jouent un rôle crucial dans l’entretien des pipelines. Ces appareils alertent les opérateurs lorsqu’un racleur de nettoyage a franchi un certain point de la canalisation. Ils veillent au bon déroulement du processus de raclage, essentiel pour le nettoyage et l’inspection des tuyaux.

Importance des indicateurs de passage des racleurs dans l’entretien et la sécurité des pipelines

Dans le domaine de l’entretien des pipelines, la sécurité est une priorité absolue. Les indicateurs de passage du racleur y contribuent de manière significative en fournissant des mises à jour en temps réel sur l’emplacement des racleurs. Ces informations permettent d’éviter les accidents et d’assurer l’intégrité du pipeline. De plus, une détection rapide permet d’éviter les blocages coûteux des pipelines et les déversements potentiels.

Différents types d’indicateurs de passage de racleur

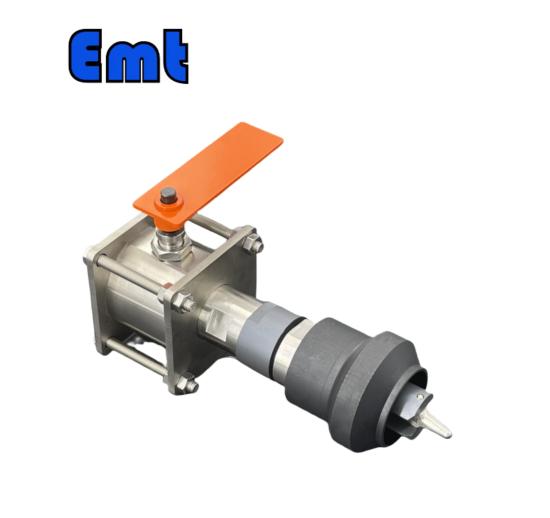

Plusieurs indicateurs de passage de racleur s’adaptent à diverses conditions de conduite. Des indicateurs magnétiques détectent le passage du porc avec un décalage du champ magnétique. Pendant ce temps, des indicateurs à ultrasons captent les sons à haute fréquence lorsque le porc se déplace. De plus, des indicateurs mécaniques signalent physiquement le passage des porcs à l’aide d’un panneau contextuel. Chaque type offre des avantages uniques, permettant des solutions sur mesure dans des systèmes de pipelines complexes.

Installation et placement

Meilleures pratiques pour l’installation d’indicateurs de passage de racleur

Consultez toujours le manuel du fabricant avant l’installation. Assurez-vous que la zone de montage est propre et accessible. Alignez les indicateurs avec le diamètre de la canalisation pour une détection précise. Fixez solidement l’indicateur pour résister aux forces de pression et d’écoulement. Testez la fonctionnalité après l’installation pour confirmer l’état de préparation opérationnelle.

Déterminer l’emplacement optimal dans un système de canalisations

Placez les indicateurs à des points stratégiques où la détection des porcs est critique. En amont et en aval des virages et des jonctions sont des points privilégiés. Tenez compte de la proximité du récepteur et du lanceur pour une communication efficace. Tenez compte de la facilité d’accès à des fins de maintenance et de surveillance. Équilibrez l’emplacement avec le flux de travail opérationnel pour améliorer la sécurité des pipelines.

Défis et solutions d’installation courants

Le traitement de matériaux de canalisations variés nécessite souvent du matériel de montage adaptable. Les conditions environnementales difficiles exigent des indicateurs robustes et résistants aux intempéries. Les contraintes d’espace peuvent nécessiter des modèles d’indicateurs compacts. Pour les interférences électromagnétiques, optez pour des indicateurs avec des composants blindés. Surmontez ces obstacles grâce à une planification minutieuse et à la sélection de modèles d’indicateurs appropriés.

Types d’indicateur de passage de racleur

| Types d’indicateurs | Un | B | C | D |

| Type intrusif | Intrusif | Intrusif | Intrusif | Non intrusif |

| Caractéristiques de l’indicateur | Type de bouton-pression | Drapeau de réinitialisation manuelle | Drapeau de réinitialisation manuelle combiné à des signaux électriques | Affichage de la date et de l’heure combiné à des signaux électriques |

Paramètres de l’indicateur de passage du racleur

| Nom | Indicateur de passage du racleur |

| Connexion | Raccord à bride/raccord à souder |

| Longueur du corps de la prise | 200 millimètres |

| Température de fonctionnement | -20 ~ 120 °C / Répondre aux exigences du client |

| NACE MR 01-75 | Oui |

| Protection contre les infiltrations | IP65/IP66 |

| Classe antidéflagrante | ExdII. BT4 |

| Retirer sous pression | Non |

| Type de déclencheur | Bidirectionnel/Unidirectionnel |

| Longueur ajustable | 0 |

| Matériau de la pièce interne | 316SS/DSS/INCONEL |

| Profondeur de l’insert | 21 mm (Bi)/13 mm (Uni) |

| Matériau de la bride/du corps | Revêtement PTFE A105N/304SS/316SS/DSS/INCONEL (selon MR) |

Entretien

Procédures d’entretien de routine

Tout d’abord, planifiez des inspections régulières pour assurer la fiabilité de l’indicateur### Maintenance

Procédures d’entretien de routine

Tout d’abord, planifiez des inspections régulières pour garantir la fiabilité de l’indicateur. Vérifiez s’il y a des signes d’usure, de corrosion ou de dommages lors de chaque évaluation. Nettoyez les surfaces et les composants de l’indicateur pour enlever les débris et les accumulations. Testez les pièces mécaniques pour qu’elles se déplacent correctement et remplacez-les si nécessaire. Vérifiez le fonctionnement des composants électroniques et recalibrez-les pour maintenir la précision. Documentez toutes les activités d’entretien pour référence et conformité futures.

Avantages de l’utilisation des indicateurs de passage de racleur

Maintenance préventive et réduction des temps d’arrêt des pipelines

Les indicateurs de passage de racleur permettent de détecter rapidement les problèmes de canalisation, évitant ainsi des défaillances majeures. Ils rationalisent les calendriers de maintenance, réduisant ainsi considérablement les temps d’arrêt imprévus. Une surveillance constante permet d’intervenir en temps opportun, ce qui permet de maintenir les pipelines opérationnels avec un minimum d’interruptions.

Amélioration de la sécurité et de la protection de l’environnement

Ces indicateurs renforcent la sécurité en prévenant les incidents qui pourraient nuire aux travailleurs et à l’environnement. Ils alertent les opérateurs des fuites ou des blocages potentiels, atténuant ainsi le risque de déversement. L’amélioration de l’intégrité des pipelines signifie également une réduction des risques de contamination de l’environnement.

Économies de coûts et amélioration de l’efficacité

L’utilisation d’indicateurs de passage de racleur permet d’améliorer l’efficacité des opérations de raclage. Ils réduisent le besoin de réparations et de nettoyages importants. De plus, ils maximisent le débit en gardant les pipelines dégagés et entièrement fonctionnels. À long terme, ces économies peuvent être substantielles, ce qui profite aux résultats de l’entreprise.

Il n’y a pas encore d’avis.