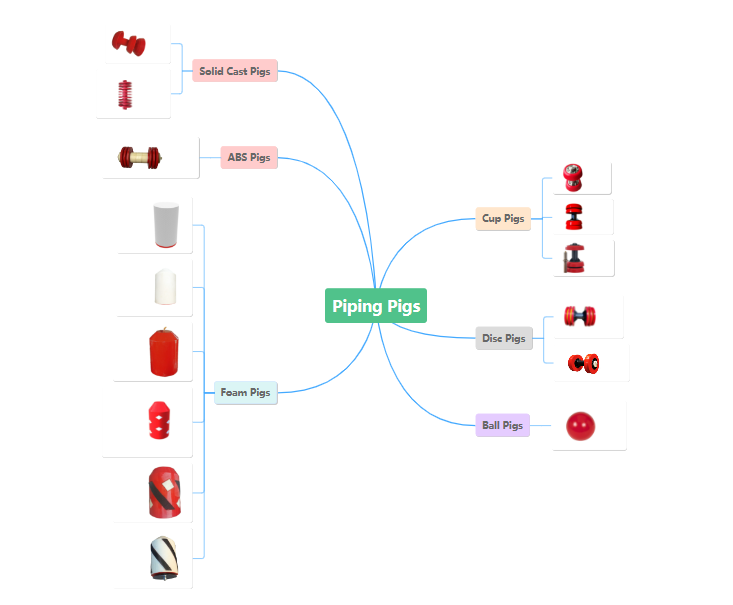

Types de racleurs de pipeline

racleur de pipeline à billes

Le matériau commun des cochons de balles est nCaoutchouc éoprène. Ils sont creux au milieu. L’épaisseur d’eux est généralement de 10% du diamètre du tuyau (30 ~ 95 mm). Il y a un clapet anti-retour à l’intérieur, qui peut contrôler le volume d’eau injectée à travers un trou d’injection d’eau ou de ventilation de gaz. Par conséquent, il peut contrôler l’interférence des cochons de balle. Les racleurs à balles nettoient principalement les fluides liquides dans le tuyau et les séparent. Il comprend la séparation de différents types d’huiles et l’élimination de l’air dans le test hydraulique d’eau du tuyau. L’inconvénient de celui-ci est sa faible capacité à éliminer les grumeaux et la poussière. Si le diamètre du tuyau de dérivation est supérieur au diamètre du tuyau principal 1/2 té, ou l’utilisation d’un té de diamètre égal, alors qu’il n’y a pas de barre de protection, il est facile de provoquer le défaut de bille coincée.

racleur de pipeline racleur en mousse de polyuréthane

La longueur des racleurs en mousse de polyuréthane est généralement de 1,75 ~ 2 fois le diamètre du tuyau. L’interférence est généralement de 25 mm ou 5% ~ 10% du tuyau. Les porcs en polyuréthane ont une élasticité élevée, ténacité et une certaine résistance à l’usure, et la déformation est supérieure à 50%. Le racleur à mousse a une forte capacité d’écoulement et est facile à passer à travers le coude du tuyau. Même en cas de blocage, il peut compter sur ses performances de déformation élevées. Ou augmentez la pression pour le faire casser, retirez le tuyau bloqué par lui-même, et il n’y aura pas d’accident de pression. Les débris de mousse du racleur de mousse n’ont aucun dommage à la paroi intérieure de la canalisation. Il convient au nettoyage des tuyaux avec revêtement de paroi intérieure. L’inconvénient est que la capacité d’enlever les débris est générale. Principalement utilisé pour l’absorption d’eau de tuyau et le nettoyage, ne peut être utilisé qu’une seule fois, car la distance de course est courte.

Mécanique racleurs de pipeline

Les racleurs de canalisation racleurs mécaniques peuvent nettoyer non seulement les accumulations de liquides, mais aussi les débris solides. Vous pouvez ajouter différentes brosses ou grattoirs pour répondre à des exigences de nettoyage spécifiques, améliorant ainsi l’effet de nettoyage. L’un de leurs avantages est une longue durée de vie ; En règle générale, les porcs mécaniques peuvent parcourir des distances de 800 à 1000 kilomètres. Les opérateurs peuvent les équiper d’équipements de traçage, de plaques de mesure, d’aimants, etc. Cependant, leur faible passivité constitue un inconvénient. Ils ne conviennent pas aux canalisations fortement déformées ou aux tuyaux avec plusieurs coudes et vannes. Dans les canalisations domestiques, les opérateurs utilisent principalement des racleurs mécaniques à coupelles et des racleurs bidirectionnels à disques.

L’interférence des racleurs à godets est généralement de 3 % à 5 % du diamètre du tuyau, ce qui leur donne une meilleure capacité de passage que les racleurs de pipeline à disques. Les racleurs à godet travaillent dans une seule direction et sont principalement destinés au nettoyage des liquides, de la poussière et d’autres saletés dans les canalisations. Les racleurs à disques ont une capacité de nettoyage plus forte que les racleurs à godets, particulièrement efficaces pour éliminer la saleté en suspension dans le tuyau. Cependant, les bonnets en cuir des cochons à disque s’usent plus rapidement et leur distance de course est plus courte par rapport aux autres options. Les racleurs à disques sont bidirectionnels, ce qui les rend utiles pour dégager les blocages lors de la mise en service du pipeline ou après de longues périodes sans nettoyage, car les opérateurs peuvent inverser le blocage.

Racleur d’étrier Racleur de pipeline Pigs

Les racleurs de pipeline à étrier peuvent mesurer des spécifications telles que la géométrie du tuyau, l’ellipticité, la rugosité et la perméabilité des soudures. Ils peuvent fournir des données de base originales, qui constituent la base de l’entretien et du nettoyage des pipelines. Le diamètre des racleurs d’étrier est généralement de 60% du tuyau. Les tasses d’entre eux ont une grande flexibilité et peuvent passer à travers 15% du trou de retrait. Les technologies clés de l’étrier racleur sont le contrôle de la vitesse, la précision de détection, la fiabilité et le traitement et l’analyse ultérieurs des données. Avant le raclage intelligent (détection dans le pipeline), le racleur d’étrier doit être lancé pour déterminer l’état interne du pipeline et tester la capacité de passage du pipeline.

Intelligent racleurs de pipeline

Le racleur intelligent comprend un capteur d’acquisition de données, un système de support, un système d’entraînement, un bol en cuir (brosse en acier), une sonde, un système d’alimentation et un système de traitement du signal. Sa longueur est de 4 à 5 fois celle du porc ordinaire. Pour inspecter le pipeline en douceur, avant de lancer le racleur intelligent, le racleur ordinaire est tiré pour nettoyer le pipeline. Le racleur d’étrier est ensuite lancé pour déterminer l’état interne du tuyau et sa capacité de passage. Les informations sur les tuyaux collectées et déterminées par le racleur intelligent comprennent la mesure de la déformation géométrique du tuyau, la bosse du tuyau, le pli, l’ellipticité, le rayon de courbure, etc. Perte de métal du tuyau, dépôt de cire et degré de corrosion ; L’emplacement, la zone et la gravité des fissures dans les pipelines.

Base de sélection des porcs

La sélection du racleur est un problème de prise de décision multi-objectifs et multifactoriel, principalement pour déterminer la résistance mécanique du racleur, la résistance à l’usure, l’adsorption, la réactivité du fluide de transport dans le pipeline et la capacité de passage, comme suit :

1) Cible de raclage. Que le tuyau soit nettoyé des impuretés liquides ou solides, prédisez la quantité d’impureté. Si l’on s’attend à plus d’impuretés de sédiments, le gazoduc peut choisir un racleur avec un trou de décharge, et le sable peut être soufflé à travers le corps de gaz du trou de décharge pour éviter le blocage.

2) Étape du cycle de vie du pipeline. Le nouveau pipeline est un résidu propre, une mesure préliminaire, un test de pression, un séchage et un fonctionnement d’essai. Le tuyau de coulée doit nettoyer les dépôts de cire et la saleté, isoler le fluide et inhiber la corrosion. La mise hors service des pipelines est le processus d’enlèvement du milieu et de remplissage de gaz inerte.

3) Déterminer les caractéristiques du fluide d’entraînement (huile, eau, gaz) du raclage.

4) Quantité d’interférence entre les porcs. Tenez compte du rayon de courbure minimum et de l’angle de courbure du tuyau, du diamètre intérieur minimum et maximum, du raccordement du tuyau de dérivation, du changement d’élévation le long de la ligne et du type, de la position et de la taille de la vanne, du té ou du coude le long de la ligne.

5) Processus de raclage. La plage des valeurs de pression motrice fournies par le tuyau (pression de service maximale admissible du tuyau, pression de fonctionnement du tuyau, changement des paramètres de température), ainsi que la plage des valeurs de vitesse possibles pour le fonctionnement du racleur et la distance maximale dont le racleur a besoin pour courir.

6) Taille de la brosse en acier et du grattoir pour l’installation du porc. Selon l’épaisseur des dépôts de cire dans le pipeline et la plage de force motrice, une considération complète.

7) La résistance mécanique, la résistance à l’usure et la réactivité du racleur en contact avec le fluide dans le pipeline.

Tendance de développement de racleurs de pipeline

La tendance de développement des porcs est de s’adapter aux exigences de l’espacement des stations sur de longues distances. Par conséquent, des exigences plus élevées seront nécessaires pour la configuration du bol du porc, la résistance du bol et la qualité de l’émetteur.

Caractéristiques principales

Les bols en cuir de support et de type plat sont fabriqués en polyuréthane avec une dureté Shore de 85HA et 80HA, respectivement.

La pression de travail du racleur est supérieure à 12 MPa,

Plage de température -30 ~ 100 °C,

Volume d’interférence 3% ;

Masse porcine 0,6t,

La différence de pression la plus faible dans la canalisation est de 0,2 MPa,

La plus longue distance d’exploitation durable est supérieure à 300 km ;

Le rayon de courbure minimum à travers le coude est de 3D (D est le diamètre extérieur du tuyau)

Et les tuyaux dont la déformation maximale ne dépasse pas 25% du diamètre du tuyau ;

Vous pouvez installer le dispositif de suivi, et il peut trouver et localiser la position de blocage à temps si un blocage se produit.

Applications

Pour la porcherie du produit, en principe : si vous pouvez le pomper, vous pouvez le pomper. Les gazoducs doivent évacuer la condensation qui s’accumule dans les zones basses. Les dépôts de paraffine dans les oléoducs de pétrole brut et d’huile minérale doivent être enlevés. En plus de nettoyer les tuyaux, il est également important de les inspecter. Utilisez un racleur pour vérifier l’état intérieur du tuyau, la soudure, l’épaisseur de la paroi et la qualité de surface. Dans de nombreux cas, le nettoyage des tuyaux peut être effectué par un porc. Les applications les plus importantes du raclage sont les suivantes : Élimination du liquide des tuyaux pour éliminer la rouille et les sédiments. En utilisant Signaleurs de porcs, l’exploitant peut connaître la situation passive des porcs.

L’application d’équipements de raclage industriels se compose de quatre tâches principales :

Plusieurs produits sont pompés à travers un seul tuyau. Utilisez une ligne de raclage pour remplacer plusieurs lignes de produits indépendantes, et le raclage est nécessaire pour chaque remplacement de produit.

Le racleur pousse le produit hors du tuyau, le nettoyant en éjectant presque complètement le produit, et peut également pousser le produit hors d’un tuyau sans aucune pente ni siphon.

Rincer le tuyau (p. ex., de l’eau) avec un nettoyant et/ou un solvant enfermé entre deux racleurs qui courent dans la même direction (raclage en tandem).

Placer un porc devant le produit peut prévenir ou réduire la formation de mousse. Pour les tuyaux initialement vides ou en pente descendante, le racleur entraîné par le produit peut être utilisé pour les transporter, en évitant de les mélanger avec l’air et de causer des problèmes de qualité du produit.

Conclusion

En conclusion, les racleurs de pipeline remplissent diverses fonctions. Chaque type offre des avantages uniques. La sélection dépend des besoins du pipeline et des capacités du racleur. Le développement se concentre sur l’efficacité à longue distance. Un raclage adéquat assure l’intégrité et la propreté des pipelines. L’adoption de porcs adaptés permet d’optimiser l’entretien et le fonctionnement. Les tendances futures pointent vers des conceptions plus résilientes. Un raclage efficace se traduit par une durée de vie prolongée des pipelines et la sécurité.

Il n’y a pas encore d’avis.