Name | Chemical Injection Quill assembly | |

| Material | Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, and also Inconel 625 | |

| Operating Temperature | -20±120 | |

| Feature | Firstly, easy Operating | |

| Secondly, high Accuracy Long Life | ||

| At last, high Efficiency, Low cost | ||

| Payment | TT/LC | |

| Advantage | Firstly, they are lightweight and flexible. | |

| Secondly, excellent Injection efficiency. | ||

| At last, accurate location tracking. |

| Model | ||||||||||||||||||||||||||||

SI | Chemical Injector Quill | |||||||||||||||||||||||||||

| -Code | Plug | |||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | |||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | |||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | |||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| – Code | Injection Nut | |||||||||||||||||||||||||||

| Nxx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | |||||||||||||||||||||||

| – Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | ||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | |||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | i.e. INCONEL | |||||||||||||||||||||||||||

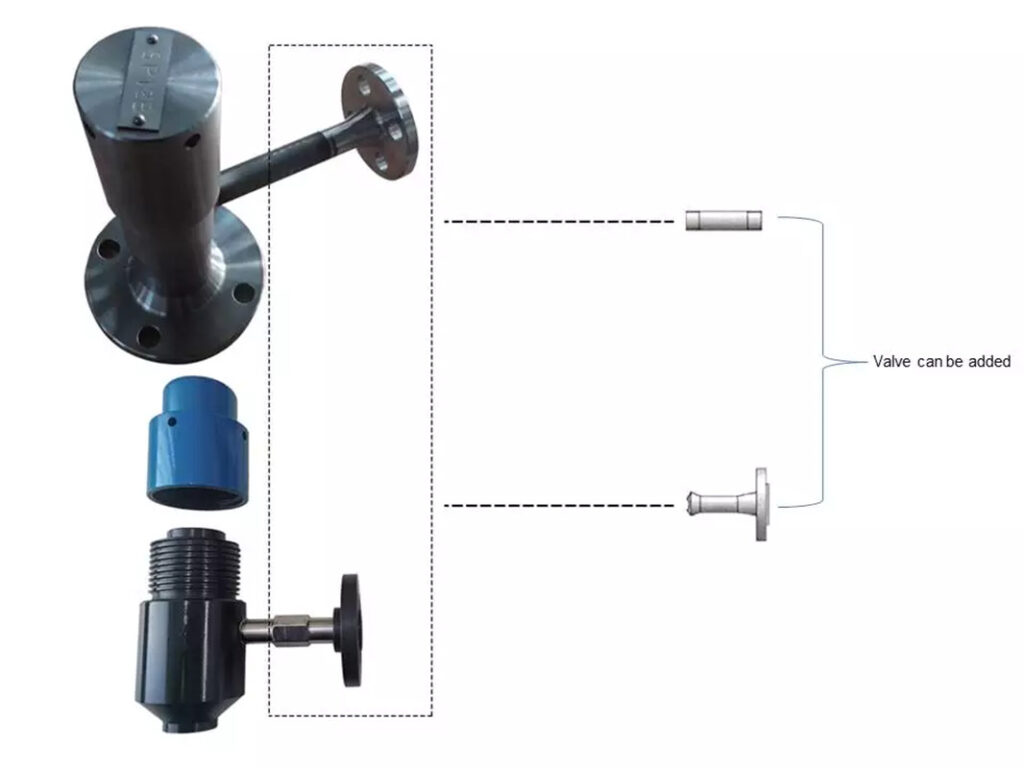

| – Code | Nipple and Valve(or end Flange)of Tee | |||||||||||||||||||||||||||

| Txx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | |||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | |||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | |||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | |||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | |||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | |||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | |||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | |||||||||||||||||||||||||

| For Example, SI-P221-N12-S122-L4″-T22SI:e.g. Sampling & Injection Assembly, P221: e.g. Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing, N12:e.g. injection Nut Connection Size is 1/4″and Material is 316LSS, S122:e.g. injection Tube Connection Size is 1/4″ and Material is 316LSS.Type of nozzle is quills L4″:For 4″pipe. T22: Nipple of Tee Connection Size is 1/2″, Nipple material is 316LSS | ||||||||||||||||||||||||||||

1. Introduction of Chemical Injection Quill

The Chemical Injection Quill is a meticulously engineered device designed for the precise dosing of chemicals into pressurized systems. Its primary function is to facilitate the direct injection of chemicals into the core of a process stream, ensuring thorough mixing and optimal dispersion. This precise control is crucial for maintaining the integrity and efficiency of diverse industrial operations.

Purpose and Definition

The quill serves as a critical component in various industrial applications, enabling exact chemical dosing with precision. Its design allows for a consistent and controlled chemical delivery. Which is essential for the processes it supports.

Significance in Industry

The importance of the Chemical Injection Quill cannot be overstated. It plays a pivotal role in safeguarding the operational integrity of systems across multiple sectors. Industries such as oil and gas, chemical manufacturing, water treatment, and pharmaceuticals rely on the precision and reliability of this device. By ensuring an even and efficient chemical mix, the quill helps maintain process consistency. Which is vital for the production of high-quality products and the safe handling of chemicals.

2. Key Features of the Chemical Injection Quill

Optimal Chemical Dispersion

The design and strategic placement of the quill guarantee that it injects chemicals directly into the heart of the fluid stream. This placement is crucial for achieving uniform chemical dispersion across the entire system. Uniform distribution is essential for ensuring consistent process results. Which is particularly critical in industries like oil and gas, chemical manufacturing, water treatment, and pharmaceuticals.

Durable Materials and Construction

Constructed from high-grade materials such as Stainless Steel 304, Stainless Steel 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625. The quill is built to withstand the harsh environments often encountered in industrial settings. These materials ensure the quill’s resistance to corrosion and chemical wear, enhancing its durability and reducing the need for frequent maintenance.

Versatility and Customization

The Chemical Injection Quill offers extensive customization options. Including various lengths, connection types, and nozzle sizes, to perfectly align with specific system requirements. This adaptability allows the quill to be tailored to meet the precise needs of different applications, ensuring safe and effective chemical introduction without compromising system integrity.

Safety Features

A key safety feature of the quill is its built-in check valve, which prevents the backflow of chemicals into the injection system. This safety mechanism is critical for protecting both the process and the personnel involved, ensuring that operations remain safe and contamination-free.

Ease of Installation and Maintenance

The quill’s design prioritizes ease of integration into existing systems and simplifies maintenance requirements. This approach significantly reduces operational downtime and facilitates routine maintenance checks, further enhancing the efficiency and longevity of the system it serves.

By incorporating these sophisticated features, the Chemical Injection Quill stands out as an indispensable tool in the arsenal of modern industrial operations, providing unmatched precision, safety, and reliability in chemical dosing processes.

There are no reviews yet.