Introduction

Chemical Injection Quills are crucial for adding chemicals to high-pressure pipelines in the oil and gas industry. They help keep equipment running smoothly and last longer. Operators use these quills to put important chemicals, like methanol, into the oil flow. This stops ice-like hydrates from forming and keeps the oil wells working well.

These quills fit into pipelines tightly to avoid leaks, even when pressures are high. They have a special pump for adding chemicals accurately or taking samples. Our expert team is always here to help you understand and choose the right quills for your needs.

Mode Selection of EMT Chemical Injection Quills

| Model | ||||||||||||||||||||||||||||

| SI | Chemical Injection Quills Access Fitting | |||||||||||||||||||||||||||

| -Code | Plug | |||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | |||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | |||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | |||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| Code | Injection Nut | |||||||||||||||||||||||||||

| Nxx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | |||||||||||||||||||||||

| – Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | ||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | |||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | i.e. INCONEL | |||||||||||||||||||||||||||

| – Code | Nipple and Valve (or End Flange) of the Tee | |||||||||||||||||||||||||||

| Txx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | |||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | |||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | |||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | |||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | |||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | |||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | |||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | |||||||||||||||||||||||||

| P221: e.g. Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary packing N12: e.g., injection Nut Connection Size is 1/4″and Material is316LSS, S122:e.g. injection The tube connection size is 1/4 ″ and the material is 316LSS. The type of nozzle is quills L4″:For 4″pipe. T22:Nippleof Tee Connection Size is 1/2″,Nipple material is316LSS | ||||||||||||||||||||||||||||

Parameters of EMT Chemical Injection Quills

Name | Chemical Injection Quills Access Fitting | |

| Material | Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, and also Inconel 625 | |

| Operating Temperature | -20~+120℃ | |

| Features | First, it is easy to operate | |

| Second, long life and high accuracy | ||

| Lastly, low-cost and high efficiency | ||

| Payment | TT/LC | |

| Advantages | First, lightweight and flexible | |

| Second, excellent injection efficiency | ||

| At last, accurate location tracking |

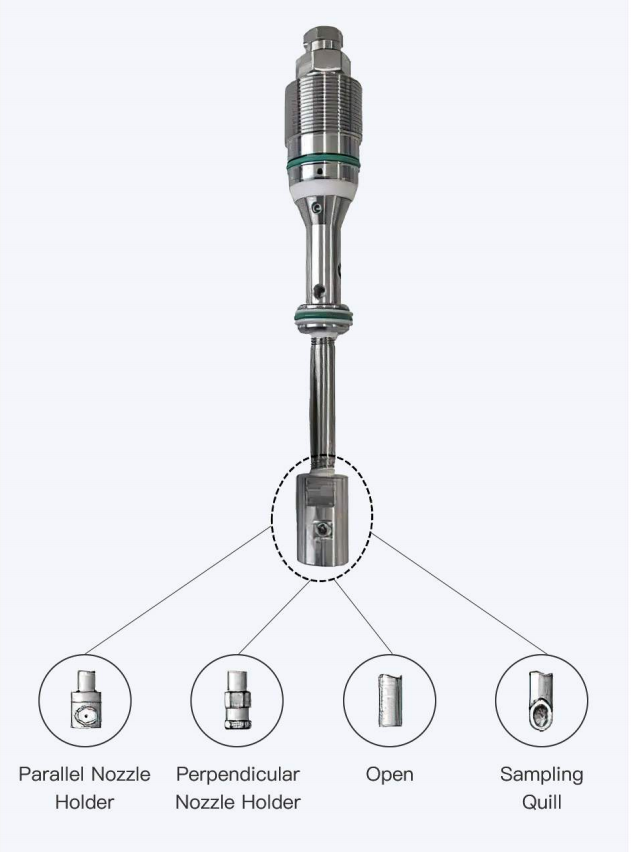

Nozzle Types of Chemical Injection Quills

Chemical Injection Quills feature four nozzles tailored for different tasks. The parallel nozzle injects chemicals directly in line with the flow, blending them instantly. In contrast, the perpendicular nozzle sprays chemicals across the flow for better mixing. The open nozzle allows chemicals to pour freely into the stream, suiting high-volume needs. Lastly, the sampling quill takes pipeline samples, essential for quality checks.

Applications of Chemical Injection Quills

Chemical injection quills inject chemicals into pipelines to prevent corrosion. They help stop blockages by keeping pipes clean. Quills evenly mix chemicals into flowing substances in the pipes. They also protect pipeline walls from harsh chemicals. You can use quills to add freeze protection chemicals like methanol. They ensure smooth operation in oil and gas pipelines. Quills assist in the controlled dosing of chemicals for process optimization. They are crucial for maintaining the quality and safety of pipeline systems.

Corrosion Prevention

Oil and Gas Industry: Quills deliver corrosion inhibitors directly into pipelines, preventing rust and ensuring the longevity of the infrastructure.

Water Treatment: In water transport lines, quills add anti-corrosive agents to guard against pipe degradation.

Pipeline Cleaning

Petrochemical Plants: By injecting solvents and detergents, quills help to dissolve and dislodge build-up, maintaining clear lines for product transport.

Sewage Treatment: Quills introduce cleaning agents to prevent blockages and maintain flow efficiency in waste management systems.

Chemical Mixing

Chemical Manufacturing: Quills are used for precise dosing and thorough mixing of reactants in process streams.

Food and Beverage: They ensure the homogeneous distribution of preservatives or additives in product lines.

Equipment Protection

Refineries: Quills inject neutralizing chemicals to protect equipment from acidic or caustic substances.

Pharmaceuticals: They add buffering agents to process lines to maintain the integrity of the equipment and the purity of the products.

Freeze Protection

Natural Gas Lines: Methanol or ethylene glycol is injected to prevent hydrate formation in cold climates, ensuring gas flows freely.

Marine Industry: Antifreeze chemicals are introduced to systems that are exposed to sub-zero temperatures to prevent icing.

Process Optimization

Oil Extraction: Accurate chemical dosing helps in separating oil from other substances, enhancing the extraction process.

Water Purification: Quills add precise amounts of disinfectants for potable water treatment, optimizing purification.

Quality and Safety Maintenance

Power Generation: They maintain water chemistry in boilers, ensuring safety and efficiency.

Aerospace and Automotive: Quills inject specific chemicals into fuel or lubricant lines to maintain quality and performance of engines.

There are no reviews yet.