Introduction of Chemical Injector

In industrial settings, a chemical injector typically functions as a vital mechanism for introducing chemicals, such as biocides, scale, or corrosion inhibitors, into a vessel or pipeline. Strategically positioned within a tank or pipe, it effectively facilitates the precise and secure distribution of chemicals, thereby ensuring they are evenly dispersed throughout the system for optimal performance.

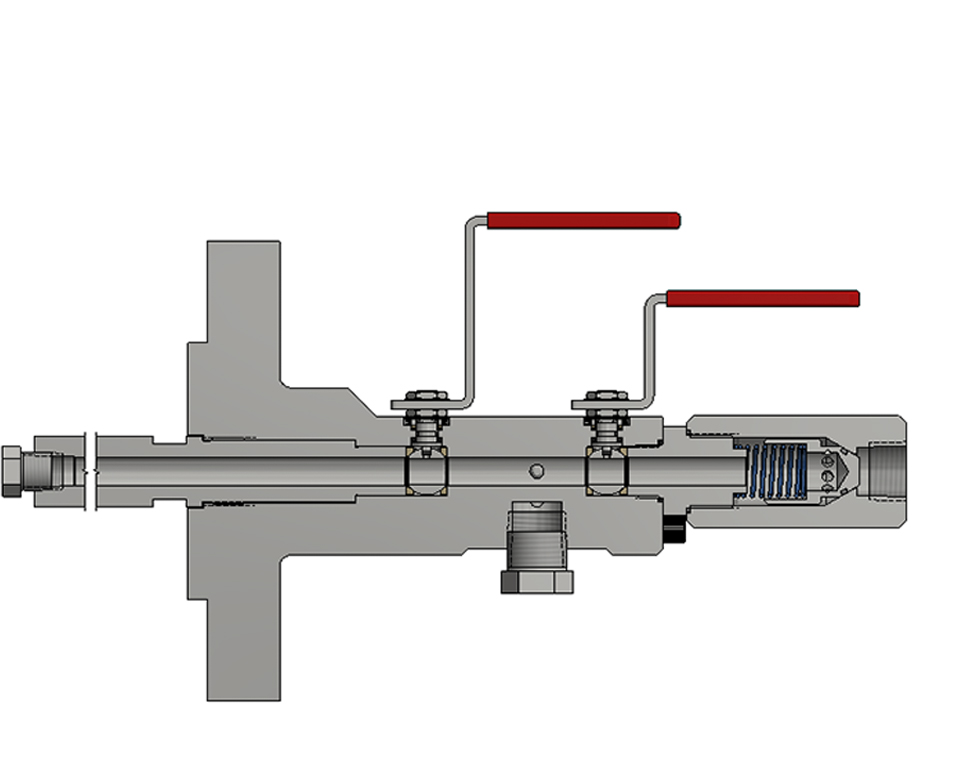

The following is the chemical injector with a DBB valve.

Introduction of DBB Valve

The working principle of the DBB valve is the action of the two sealing slides installed on the plug.

Close the valve

When the valve is closed, first rotate the handwheel, then rotate the plug and seal slide 90°. And then move the cock down and push the seal slide toward the body cavity cover with the movement of the plug. Until the elastic seal ring is evenly squeezed to the upper and lower ends of the valve hole to form a seal.

Open the valve

When the valve is opened, first rotate the hand wheel to lift the cock and pull the sealing slide back from the sealing surface on both sides of the valve body. When the slide plate is completely withdrawn from the sealing surface of the valve body, continue to turn the handwheel. So that the cock and seal slide plate rotate 90° and the valve is in the open position.

Features of DBB Valve

(1) During the valve switching process, the valve body sealing surface avoids contact with the sliding plate sealing surface; consequently, the sealing surface undergoes no friction or wear. This absence of abrasion ensures a prolonged service life for the valve and necessitates only minimal switching torque.

(2) Regarding valve repair, there’s no need to detach the valve from the pipeline. Rather, just disassemble the bottom cover of the valve and substitute a pair of slides.

(3) The valve body and cock are reduced in size, which can help to cut costs.

(4) The inner cavity of the valve body is plated with hard chromium, making the sealing area both hard and smooth.

(5) The elastic seal on the slide is made of fluorine rubber and is molded into the groove on the slide’s surface. A metal-to-metal seal with a fire protection function backs the elastic seal.

(6) The valve has an optional automatic discharge device that, after the valve is completely closed, prevents abnormal pressure increases in the valve chamber and checks the valve’s effectiveness.

(7) The valve switch indicator is synchronized with the switch position to accurately display the valve’s status.

Selecting the Right Chemical Injector with the DBB Valve

A. Factors to Consider When Choosing a System

- Assess the chemical compatibility; ensure materials can handle specific chemicals.

- Determine the required injection pressure and flow rate.

- Consider the viscosity and temperature of the injecting chemical.

- Evaluate the system’s resistance to corrosion and wear.

- Check for precision in the injector’s dosing capabilities.

- Ensure the DBB valve meets industry safety standards.

- Account for the operational environment; it influences material selection.

- Look for ease of maintenance and the availability of spare parts.

- Factor in the injector’s compatibility with existing systems.

- Prioritize systems with reliable customer support and warranties.

The Design and Structure of a Chemical Injection Quill

The Chemical Injection Quill, featuring an RF flange for strong connectivity, ensures efficient and safe chemical injection. Its retrievability simplifies maintenance, enhancing process efficiency. The ‘sampling type’ nozzle enables controlled chemical distribution, with other designs available for varied needs. With an IP66 rating and Exd II BT4 classification, it’s fit for harsh, explosive areas. Materials like stainless steel and Inconel offer chemical and environmental resistance, ensuring durability.

Key Components of a Chemical Injector

Injection Nozzle

The injection nozzle delivers chemicals into the stream.

It ensures the distribution of chemicals in the process.

Nozzles vary in size for different flow rates.

Check Valves

Check valves to prevent backflow, protecting the injector.

They ensure a one-way flow of chemicals.

Materials must resist the chemicals used.

Control System

Control systems regulate the injection rate.

They can be manual or automated for precision.

Systems often include sensors for real-time adjustments.

Common Chemicals Used in Injection Systems

Corrosion Inhibitors

Corrosion inhibitors extend the pipeline’s life.

They form a protective layer inside the pipes.

Scale Inhibitors

Scale inhibitors prevent mineral deposits.

They keep the flow consistent and unobstructed.

Biocides

Biocides control microbial growth in the system.

They are essential for maintaining system hygiene.

In summary, various chemicals are integral to the maintenance of injection systems. Corrosion inhibitors play a pivotal role in prolonging pipeline life by forming a protective layer within. Furthermore, scale inhibitors are crucial for preventing mineral buildup, thus ensuring a steady and clear flow. Lastly, biocides effectively manage microbial growth, proving indispensable for preserving system hygiene.

Conclusion

In conclusion, choosing the right chemical injector with a DBB valve hinges on careful evaluation of compatibility, pressure, flow, and environmental factors. Vendor selection demands diligence, seeking those with proven quality and strong support. The components of the injection system are crucial for effective chemical delivery and system longevity. By prioritizing these elements, industries can ensure efficient and reliable operations, safeguard their investments, and maintain high operational standards.

There are no reviews yet.