Introduction of Fluororubber Pipeline Cleaning Pigs

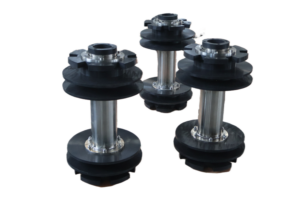

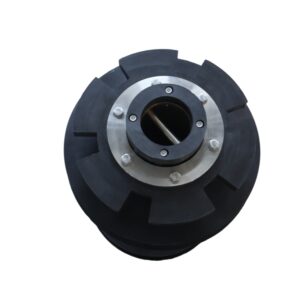

Due to its double-ended design, the EMT Fluororubber Pipeline Cleaning Pig can travel forward and backward in the pipe. It can be precisely adapted to the medium that needs to be moved using a prestressed adjustment to ensure the hygiene and cleanliness of the pipeline system. Save up to 80% of your regular water consumption!

Our pipe cleaners move smoothly through common DIN bends, tees and ball valves, two-seat valves that prevent mixing, and two-tube heat exchangers. Operators can know the location of the pig at all times in all equipment components. This is secured by a special magnet integrated into the pig.

Fluororubber Material

Compared with other synthetic rubbers, fluorine rubber has significant advantages in heat resistance, oil resistance, and chemical resistance.

Main Properties of Fluororubber

The properties of fluorine rubber are mainly shown as follows:

Fluorine rubber has good mechanical properties. It has good tensile strength and hardness but poor elasticity at room temperature. Fluorine rubber, in terms of heat and temperature resistance and aging resistance, can be comparable to silicone rubber, better than other rubber. For example, type 26· can work at 250 °C for a long time. It is very stable to sunlight, ozone, and climate aging. This is another non-fluorine rubber that cannot compare. The compressive deformation resistance of fluoro rubber can be enhanced by improvement, and its excellent wear resistance can be used in the production of static and dynamic seals. If the friction coefficient of fluorine rubber is about 0.80, that of butadiene rubber is 0.90~1.05. Fluororubber has good wear resistance. It has high chemical stability. Fluorine rubber is one of the most dielectric-resistant elastomers of all. This enables it to operate in a variety of harsh chemical environments. At the same time, fluorine rubber also has good vacuum resistance and self-extinguishing fire resistance.

Importance of Pipeline Cleaning

In the long-term use of natural gas pipelines, operators regularly pig the lines to gain a clear understanding of the internal conditions. If they detect defects, they can promptly repair and maintain the pipeline. This practice also helps reduce pipeline costs. Currently, our country employs pigging technology to accurately gather relevant data, facilitating baseline evaluations of gas transmission pipelines. These evaluations, in turn, inform the overall assessment and strengthen the gas pipelines’ protection levels, ensuring their long-term safe operation and preventing gas leaks due to corrosion and pipeline perforation.

Importance of Pipeline Cleaning Pigs

Pipeline cleaning is crucial for maintaining flow efficiency. It prevents blockages and minimizes wear. Enter Fluororubber Pipeline Cleaning Pigs. These tools excel at pipeline maintenance. Their durable material withstands harsh chemicals. They ensure pipelines stay in prime condition. With these pigs, operators can prevent costly downtime. They are instrumental in extending pipeline lifespans.

To ensure the efficiency of natural gas transmission pipelines in normal operation, it is necessary to carry out timely and effective pigging work on natural gas pipelines. In particular, hydrogen sulfide corrosion products gathered in the gas pipeline due to long-term use, condensate water, and debris brought into the pipeline. To prevent blocking the gas pipeline and equipment failure, it is necessary to carry out regular pigging work on the pipeline. To ensure the stability and safety of the pigging operation, it is necessary to ensure that the pig can be recovered after it is issued. Then, it is necessary to adjust the operation process of the pipeline in the working area according to the actual use of the pipe network. The reasonable running speed of the pig is controlled without affecting the user below.

Types of Pipeline Cleaning Pigs

Foam pigs offer flexibility and light cleaning. They navigate easily through bends and valves in pipelines.

Next up, cup pigs. These feature rubber cups for more thorough scraping and debris removal.

Disc pigs come equipped with discs. They provide aggressive cleaning and are ideal for removing tough deposits.

Moreover, ABS pigs boast a hard plastic construction. They excel at moderate cleaning and displacement tasks.

Solid-cast pigs, on the other hand, are dense and heavy-duty. They tackle severe wax and scale buildups effectively.

Finally, fluoro rubber pigs stand out for their chemical resistance. They maintain integrity in corrosive environments, ensuring longevity.

Applications of Fluororubber Pipeline Cleaning Pigs

Oil and Gas Industry:

Fluororubber Pipeline Cleaning Pigs are vital in the oil and gas sector. They ensure the efficient and safe transport of hydrocarbons. By removing deposits like wax, scale, and sand, they prevent blockages. This not only optimizes flow but also minimizes wear on the pipeline, reducing the risk of leaks or bursts that could have environmental and safety repercussions.

Water Treatment Industry:

In water treatment, these pigs play a pivotal role in maintaining pipeline integrity. They clear away harmful mineral deposits and biofilms that can affect water quality. Regular pigging with fluororubber pigs helps to ensure that water treatment processes run smoothly. This is essential for providing clean water to communities and industries.

Other Notable Industries:

Fluororubber Pipeline Cleaning Pigs also serve critical functions in a variety of other industries. In the food and beverage sector, they help to maintain strict sanitation standards by preventing cross-contamination and ensuring product quality. The chemical industry benefits from the material’s resistance to corrosive substances, which helps to maintain the purity of chemical products being transported. Additionally, industries that handle specialized products, such as pulp and paper or petrochemicals, rely on these pigs to keep their pipelines clear and functioning efficiently.

-300x217.jpg)

There are no reviews yet.