What is a Pig Indicator?

A pig indicator is an essential tool designed to monitor the status of cleaning pigs within pipelines. Initially, as the pig, sphere pig, scraper, and other cleaning tools journey through various sections of the pipe and approach the receiver, the indicators play a crucial role. They can accurately detect the presence of these tools and, consequently, provide timely feedback to the operator. Additionally, the indicators serve as an alert system, informing the operator if a pig becomes lost or gets stuck at the receiver. Thus, by utilizing the information from pig indicators, operators can reliably ascertain whether the cleaning pig has successfully passed through a section of the pipeline or not.

Our popular intrusive indicator series employs a trigger intrusion into the pipeline. Besides, our non-intrusive pig indicators confirm the passage of pigs carrying magnets. Not sure which is right for you? Contact our EMT team today for more information or a quote! Our EMT team will give you the most competitive price!

Types of EMT Indicators

Intrusive Pig Indicators

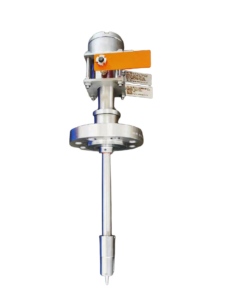

Pig Indicator, Flange Connection

Features

It is an intrusive type of pig indicator with a flange connection. According to ASME B16.5, the installation type is a 2” flange. The plug body length is usually 200mm, which can change according to customer needs. The operating temperature ranges from -20 degrees to 120 degrees. Its ingress protection is IP66. The explosion-proof class meets Exd II BT4. It cannot be removed under pressure.

Parameters

| |

| Name | Pig Indicator |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | —20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

20mm Adjustable Pig Indicator-Flange Connection

Features

The standout feature of this Pig Indicator is its adjustable nature, which accommodates a deviation of up to 20mm in insertion depth. This flexibility means that if the trigger has not been inserted to the exact required length, the operator can easily adjust it. This adjustability ensures that the insertion depth into the pipe is precise, enhancing the reliability of the pigging operation.

Parameters

| |

| Name | 20mm Adjustable Pig Indicator |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | —20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 20mm |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Removable Pig Indicator, 2” Welded Base, NPT Connection

Features

This Pig Indicator’s prime benefit lies in its adaptability; it tolerates an insertion depth variance of up to 20mm. Such versatility allows for correction if the trigger is not set to the precise length initially required. Operators can effortlessly fine-tune the position, thus guaranteeing exact insertion depth for optimal accuracy, which in turn bolsters the dependability of the pigging process.

Parameters

| |

| Name | Removable Pig Indicator |

| Connection | 2” Welded Base, NPT Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 20mm |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Base/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Pig Signaler- 2” Base Welded

Features

The connection is 2” base welded. The material is usually the same as the pipe so that it can weld with the pipe successfully. In addition to its standard 2” base welded connection, the welded base pig indicator offers several other advantages. The material selection, typically matching that of the pipeline, ensures a cohesive and strong weld. This compatibility minimizes potential weak points at the juncture, leading to a more secure and leak-proof operation. Furthermore, a welded base provides enhanced structural integrity, allowing the indicator to withstand high-pressure environments and aggressive substances that may flow through the pipeline. The robust construction also means reduced maintenance and a longer service life, making it a cost-effective choice for long-term pipeline monitoring.

Parameters

| |

| Name | Pig Indicator |

| Connection | 2” Welded Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

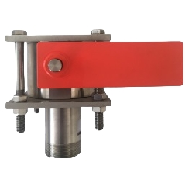

Removable Pig Indicator On a Flange Valve

Features

The product is economical due to its brief and inexpensive retriever. It also boasts quick and easy installation and removal, which can be performed without interrupting the pipeline’s operation. This feature significantly reduces downtime and enhances productivity. Its design allows for clear and immediate visual confirmation of the pig’s passage, improving operational efficiency. Additionally, its compatibility with flanged connections ensures a secure and reliable seal, reducing the risk of leaks. The flange-mounted design also facilitates accessibility for maintenance and inspection. It further contributes to its overall practicality and cost-effectiveness in pipeline management.

Parameters

| |

| Name | Removable Pig Indicator On a Flange Valve |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01-75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Removable Pig Indicator with a Ball Valve

Features

It is engineered for easy integration into pipeline systems. Its ball valve construction allows for maintenance and inspections with minimal operational disruptions. The valve’s tight seal when closed ensures leak prevention and enhanced safety. When open, the valve maintains full pipeline flow, optimizing system efficiency and minimizing pressure drops. The detachable nature of the indicator facilitates convenient servicing or replacement without the necessity of a complete system shutdown, thereby reducing operational downtime and costs. This design streamlines pipeline management, offering a more adaptable approach.

Parameters

| |

| Name | Removable Pig Indicator with a Ball Valve |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Removable Pig Indicator with an Isolation Valve

Features

It isolates sections, ensuring uninterrupted flow during inspections. The valve’s tight seal protects against leaks, enhancing operational safety. It’s built tough for long-term use, resisting pressure and corrosion. The setup is simple, allowing for quick installations. Clear visual signals enable prompt pig location. This tool streamlines routine checks, boosting efficiency and cost savings.

Parameters

| |

| Name | Removable Pig Indicator with an Isolation Valve |

| Connection | Welded Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01-75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Removable Pig Indicator with a DBB Valve

Features

The DBB valve provides a fail-safe seal for maintenance without stopping flow. It isolates the indicator, allowing safe, live-line intervention. Installation is user-friendly, leading to reduced setup time. Its robust design ensures longevity under high pressure. The indicator gives a clear visual signal for pig passage. This design boosts safety and efficiency in pipeline operations. It also cuts downtime and saves costs, optimizing pipeline management.

Parameters

| |

| Name | Removable Pig Indicator with a DBB Valve |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Non-intrusive Pig Indicators

| |

| Name | Non-intrusive Pig Indicator |

| Operating Temperature | —39.8℃/80℃ |

| Operating Humidity | 41%~83% |

| Sensor Type | Magnetic Induction |

| Signal Switch Type | SPDT |

| Passing time | ±2s |

| Cleaning Pig Speed Range | 0.2-10 m/s |

| Switch Capacity | 2A |

| Reset Type | Auto Rese |

| Cable Joint Type | M20*1.5、 1/2NPT F |

| Explosion-Proof | Exd IICT6 Gb |

| IP Grade | IP65 |

Indicator Types

| Indicator Types | A | B | C | D |

|  |  |  | |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Non-intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Working Principle

The working principle of the Pig Indicator is based on the interaction between the pig moving through the pipe and the trigger mechanism of the indicator.

The pig indicator should be placed precisely inside the pipe near the wall. It was an intrusive type of pig indicator. When the pig passes, the Pig Indicator trigger is activated to provide the operator with the passage status of the pig.

After the pig has passed, the Pig Indicator’s flag will rotate 90 degrees. Initially, the flag is in a horizontal position, and after triggering the trigger, it moves to an upright position. The change in the direction of the flag provides a visual indication of the pig’s position in the pipe.

Then the operator can determine the location of the cleaning pig based on the position of the flag. This provides a simple and effective way to monitor the progress of the pig through the pipe. Pig Indicator ensures that any cleaning or inspection process goes according to plan.

Once the pig has passed and the monitoring process is complete, the pig indicator’s flag can be reset for the next use. This is done by flipping it counterclockwise and returning it to its original horizontal position, ready for the next pigging.

There are no reviews yet.