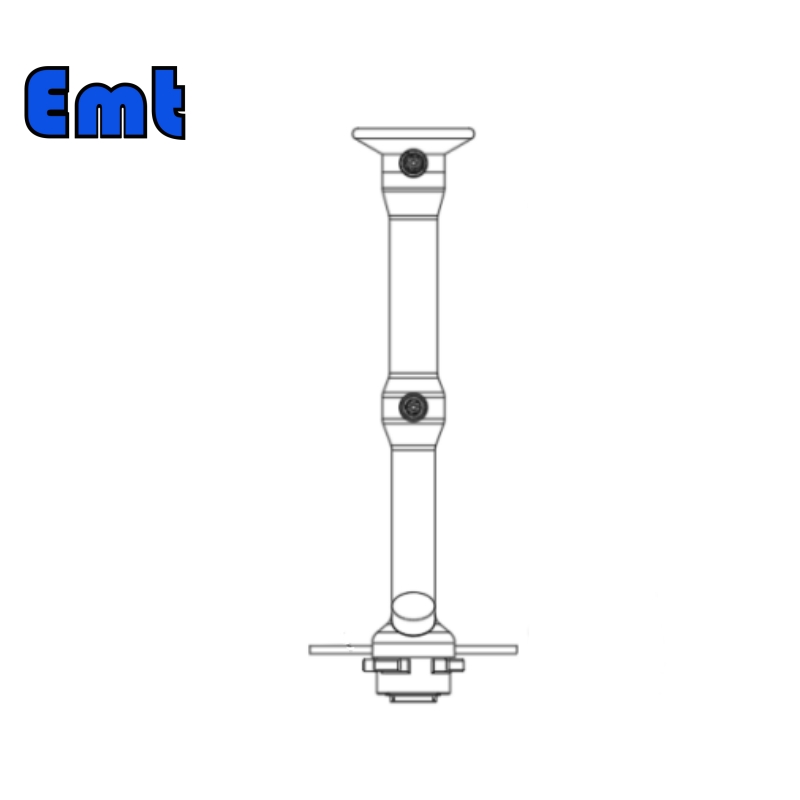

Introduction to Manual Hydraulic Retriever Tool

The Manual Hydraulic Retriever Tool is a specially designed device for extracting components in a variety of industrial applications by controlling the hydraulic mechanism. It is manually operated, allowing precise manipulation of fluid pressure and safe and efficient retrieval of parts. In situations where precise handling and positioning are critical, the tool is highly valued for its reliability and ease of use.

Manual Hydraulic Pump

Hydraulic pumps usually do not require any special maintenance. However, when the pump is to be stored for a period of time after a series of operations, the following instructions should be followed:

Visual examination.

Perform a visual inspection of pumps and hydraulic hoses to ensure all components are in good condition. Pay special attention to the following points:

Hydraulic hose. There should be no obvious damage to the surface of the hydraulic hose.

Quick coupling. They should be easy to connect and disconnect, and should not have any external or internal damage.

Pressure gauge. The pressure gauge should be intact and respond immediately to an increase in pressure.

Replace the oil in the reservoir.

Hydraulic oil may be contaminated by moisture or other liquids/gases in the line and should be replaced; This prevents potential internal corrosion of the pump that may occur later.

The following steps should be performed:

- Completely empty the oil tank.

- Fill the tank with new hydraulic oil.

- Connect the hydraulic hose to the pump.

- Unscrew the quick-connect couplings from the free end of the hydraulic hose.

- Pump 10-20 strokes in both “RETRIEVE” and “INSTALL” modes, making sure that the new hydraulic oil flows through both hydraulic hoses.

Reconnect the quick connection connector to the hydraulic hose.

If further maintenance or repair (such as replacing seals) is required, refer to the “Spare Parts List” that comes with the pump. For any further maintenance or spare parts, contact the pump manufacturer directly.

Manual Hydraulic Pump Common Troubleshooting

| Fault Phenomenon | Reason | Handling Method |

| Pump No Pressure

| 1. system leakage 2. the switch is not set properly 3. hydraulic oil internal leakage | 1. Send to the factory for repair 2. Send to factory for repair 3. Check seal |

| Handle lift | 1. Hydraulic oil internal leakage | 1. Check seal |

| Pump No Oil

| I. Too little oil 2. The inner filter is too dirty 3. Seal failure | 1. Check fuel 2. Change filter 3. Send to the factory for repair |

| Insufficient pump pressure

| 1. Too little oil 2. Seal failure 3. The switch is not set properly 4. Premature relief valve operation 5. System leakage | 1. Check fuel 2. Send to factory for repair 3. Send to factory for repair 4. Check the safety valve 5. Send to the factory for repair |

| The handle on the pump is weak | 1. system leakage | 1. Send to the factory for repair |

| The upper handle of the pump has an elastic action | 1. Air in the system 2. There is too much oil in the pump tank | 1. Repeat the operation several times to remove air 2. Check fuel |

Manual Hydraulic Retriever Tool Assembly List

| Number | Model | Name | Quality |

| 1 | EMT-HRTV-000-1 | Shell | 1 |

| 2 | EMT-HRTV-000-2 | Hydraulic hollow shaft | 1 |

| 3 | EMT-HRTV-000-3 | Hydraulic solid shaft | 1 |

| 4 | EMT-HRTV-000-4 | Hammer nut | 1 |

| 5 | EMT-HRTV-000-5 | Connecting nut (locking nut) | 1 |

| 6 | EMT-HRTV-000-6 | Hydraulic inlet valve body | 1 |

| 7 | EMT-HRTV-000-8 | Supporting wheel | 1 |

| 8 | EMT-HRTV-000-7 | Valve stem | 1 |

| 9 | DEEDLE VAVLE | Air release valve | 1 |

| 10 | Y60-1 | Pressure gage | 1 |

| 11 | EMT-HRTV-000-22 | Lock the seal ring | 1 |

| 12 | EMT-HRTV-000-19 | Hydraulic outlet quick connector | 1 |

| 13 | EMT-HRTV-000-16 | Hydraulic solid shaft locking nut | 1 |

| 14 | QF-11 | Hydraulic inlet quick connector | 1 |

| 15 | PTFE sealing ring | 1 | |

| 16 | PTFE sealing ring | 1 | |

| 17 | PTFE sealing ring | 1 | |

| 18 | PTFE sealing ring | 1 | |

| 19 | PTFE sealing ring | 1 | |

| 20 | O-ring | 1 | |

| 21 | Needle valve seal ring | 1 | |

| 22 | LS-8 | M8 inner hexagon bolt | 6 |

| 23 | SB-1 | Handwheel | 2 |

| 24 | M6 top wire | 6 | |

| 25 | O-ring | 1 | |

| 26 | O-ring | 1 | |

| 27 | O-ring | 1 | |

| 28 | EMT-HRTV-000-13 | Detent ring | 1 |

| 29 | Joint | 2 |

Conclusion

In conclusion, the Manual Hydraulic Retriever Tool and Manual Hydraulic Pump stand as crucial tools in industrial settings. They enable precise component extraction and manipulation, ensuring both precision and safety. Regular maintenance, such as visual inspections and fluid changes, is essential. These actions guarantee the tools’ reliability and extend their lifespan. Adhering to these maintenance guidelines prevents downtime and maintains operational efficiency. Users must continuously monitor their equipment’s condition and promptly address any signs of wear or malfunction. By doing so, they uphold the highest standards of safety and efficiency. For any needs, please contact our EMT team.

There are no reviews yet.