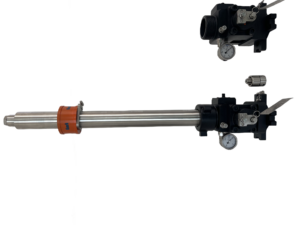

Our company has developed a pressurized disassembly tool that allows for the removal of corrosion coupons without the need for pipeline depressurization or shutdown. Its main components are made of stainless steel, which is resistant to acids, alkalis, and corrosion. This Mechanical Retrieval Tool and Service Valve operates through mechanical contact and is characterized by its sensitive and reliable action.

Introduction

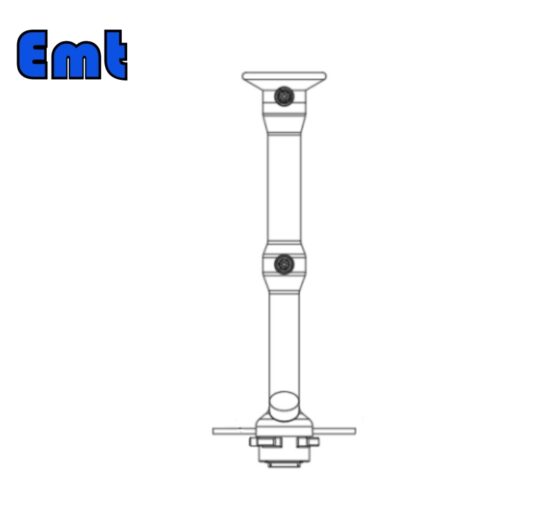

The EMT Mechanical Retrieval Tool and Service Valve is a top-tier solution for managing probes and coupons under full operational pressure. This tool integrates smoothly with most 2” access systems from leading corrosion monitoring vendors. It operates at pressures up to 6,000 psi or 420 bars, and temperatures as high as 400 °F/204 °C, setting industry standards.

Featuring a service valve with a built-in bleed-off valve, the EMT Tool ensures effective drainage even at the 12 o’clock position. Its compatibility with 2″ mechanical fittings expands its versatility across different systems. Additionally, the tool includes a unique bypass valve technology with replaceable soft tips, enhancing performance and lowering maintenance costs.

Safety and compliance are critical. The EMT Tool complies with the stringent NACE MR0175 and the EU Pressure Equipment Directive (PED). It operates on a telescopic principle with a fixed inner barrel and a mobile outer barrel. This design allows for easy insertion and retrieval by simply adjusting the outer barrel under balanced pressure.

Moreover, the EMT Tool is designed for user-friendly maintenance. Operators can disassemble the tool for cleaning without needing to replace the seals, providing a significant advantage over competitors.

Specifications

- Seamlessly integrates with 2” systems.

- Operates up to 6,000 psi, 420 bars.

- Temperature capacity of 400 °F/204 °C.

- Service valve with built-in bleed-off.

- Compatible with 2″ fittings.

- Features unique bypass valve technology.

- Replaceable tips reduce maintenance costs.

- Meets NACE MR0175 and EU PED standards.

- Uses a telescopic mechanism for ease of use.

- Allows easy disassembly for cleaning.

| Name | Mechanical Retrieval Tool with Single Service Valve | ||||||

| Max. Device Length (mm) | 150 | 240 | 350 | 425 | 640 | 920 | 1170 |

| Mechanical Retrieval Tool Length extended, including single valve | 1159 | 1339 | 1564 | 1709 | 2139 | 2700 | 3200 |

| Removal clearance with single valve | 1459 | 1640 | 1864 | 2009 | 2439 | 3001 | 3501 |

| Mechanical Retrieval Tool weight (kg) | 23.5 | 25.5 | 27.5 | 29.5 | 34 | 40 | 45.5 |

| Retriever kit approximate weight (kg) including single valve (13 kg) | 65 | 67 | 69 | 71 | 75 | 81 | 87 |

| Name | Mechanical Retrieval Tool with Double valve | ||||||

| Max. Device Length (mm) | 150 | 240 | 350 | 425 | 640 | 920 | 1170 |

| Mechanical Retrieval Tool Length extended, including single valve | 1326 | 1506 | 1732 | 1876 | 2306 | 2866 | 3366 |

| Removal clearance with single valve | 1626 | 1806 | 2032 | 2176 | 2606 | 3166 | 3666 |

| Mechanical Retrieval Tool weight (kg) | 23.5 | 25.5 | 17.5 | 29.5 | 34 | 40 | 45.5 |

| Retriever kit approximate weight (kg) including double valve (13 kg) | 74 | 76 | 78 | 80 | 84 | 90 | 96 |

Equipment Structure

- Hammer Nut – Connects the base to the Service Valve (PTFE coated).

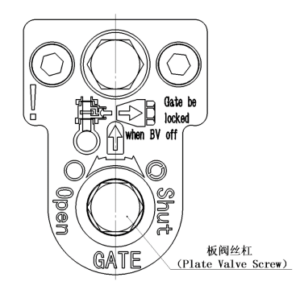

- Service Valve – Connects to the Retrieval Assembly, used for pressure regulation inside the tool while under pressure (PTFE coated).

- Bleed Valve – Used for releasing internal pressure in the tool while under pressure (stainless steel).

- Bypass Valve – Used for internal pressure balancing in the tool while under pressure (stainless steel).

- Adapter – Used to connect the corrosion coupon to the Retrieval Assembly (stainless steel).

- Plug Drive – Drive component used for the installation and removal of corrosion coupons (stainless steel).

- Plug Lifter – Used for the linkage between internal and external magnetic components (strong magnetic steel).

- Stop Block – Used to secure the external magnetic component, the Plug Lifter (stainless steel).

- Retrieval Assembly – Connects to the Service Valve, used for lifting and installing corrosion coupons (stainless steel).

Conclusion

Corrosion coupons are essential equipment used to detect or assess the corrosion status of pipeline systems. They can accurately display the internal corrosion conditions, aiding in the maintenance and upkeep of pipelines.

Currently, the corrosion coupons used both domestically and internationally generally meet the requirements for detecting pipeline corrosion. However, most require pipeline depressurization and shutdown, leading to significant economic losses. Based on these reasons, our company designed the Mechanical Retrieval Tool and Service Valve.

There are no reviews yet.