Features of Monolithic Insulation Joints

The Monolithic Insulation Joint ranges from DN15 to DN 3000 mm. Its design pressure ranges from PN 1.6 to PN 42MPa. The materials of Monolithic Insulation Joints includes carbon steel, low alloy steel, stainless steel, duplex stainless steel, nonferrous metal and metal composite materials, of which there are more than 30 varieties. The working temperature is from minus 40 °C to plus 240 °C. Therefore, it is suitable for various types of oil, gas and chemical mediums. Monolithic Insulation Joints can be used above ground, underground, and underwater. Besides, we provide permanent, free maintenance. Our insulation joints can meet all the standards and requirements at home and abroad. We have a perfect quality control system, so we can meet various stringent tests of the insulation joint. Process inspection, final inspection, and inspection by the user or third-party organizations are always welcome.

The characteristics and level of our technology

The design temperature of Monolithic Insulation Joints is at most 300 °C, while the common work temperature is 240 °C. It is suitable for steam, thermal oil, and high-temperature medium. Our research and development team has made full use of new material and made new achievements. Polyimide composite material and bisphenol, a modified silicone, were creatively put into the production of insulating joint, which greatly improved the temperature resistance level of the product.

Polyimide (PI) is a new type of polymer material, and it has been successfully applied in the Shenzhou, change project. It has good temperature characteristics. Its design temperature can reach at least 600 °C. Besides, it can work at 333 °C in long-term. It has many advantages, such as, a non-brittle crack at -269 °C, mechanical strength, good chemical stability and excellent electrical insulation properties. PI improves the insulation joint temperature resistance in essence. The product is China’s patent (Patent No.: ZL200820074213.9)

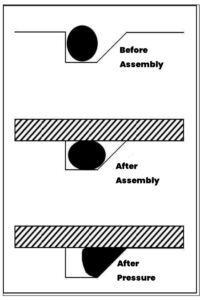

Schematic of working process of O ring in trapezoidal groove

Usually, there are two kinds of insulating joint seals: theO” ring and “U” ring. ZJ3 uses an “O” ring structure. Compared with “U” ring, “O” sealing ring has the advantages of simple production process and low cost. Orgnatic material aging and some other factors can affect its overall rigidity. But classical traditional “O” ring sealing groove is designed for direct export (in almost all drawings of Chinese petroleum). It is a typical static seal.

The “O”ring of ZJ3 is different. It is a trapezoidal, straight and groove side slope. The O ring is arranged in a groove as an integral pressure object, so it will bear pressure more tightly along the incline. The O ring can maximize display of the elastic modulus. To ensure that the system does not leak, high-reliability monolithic Monolithic Insulation Joints can effectively block the loss of stability of a small gap in the case of stress-induced instability of the system. The seal ring has never never changed because there have been no structural leakage failure case so far.

Specifications of Monolithic Insulation Joints

| Insulating Joint Upgrade I | ||

| Before Upgrade | After Upgrade | |

| Reinforced waterproof insulating joints | Super waterproof insulating joint | |

| Features | Suitable for wet soil and flooded areas | Suitable for: ultra deep wading area |

| Waterproof depth: < 5 meters | Waterproof depth: 100-1000 meters (more than 1000 meters on-demand customization) | |

| Suitable for: underwater and marine oil and gas exploration and transportation pipelines | ||

Ugraded Monolithic Insulation Joints

Insulating Joint Upgrade I | |

| Super waterproof insulating joint | |

| Features | Suitable for: ultra deep wading area |

| Waterproof depth: 100-1000 meters (more than 1000 meters on-demand customization) | |

| Suitable for: underwater and marine oil and gas exploration and transportation pipelines | |

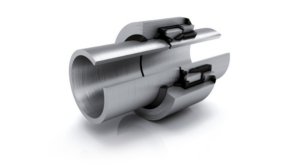

Insulating Joint Upgrade II-High Torque Type Insulating Joint

The unique meshing seal structure exhibits superior anti-torque performance compared to conventional insulating joints, enabling it to withstand design torque levels exceeding 70% of the piping’s yield strength. This surpasses the EU standard by more than threefold, making it a world-leading solution. These high torque resistant insulating joints are particularly suitable for areas with unstable geological conditions and high geological hazards such as settlements, landslides, earthquakes, and volcanoes. They serve as the strongest link in ensuring the transmission pipeline’s resilience during geological disasters by effectively resisting abnormal torque influences and guaranteeing safe and uninterrupted pipeline transportation.

Insulating Joint Upgrade III-Insulating joints online monitoring device

Insulating joints online monitoring device is an online testing delivery device for insulating joints, comprising of two polar probes (our company’s patented product) and a wireless remote data acquisition card for internal content. Users can download our company’s software and APP to detect the real electrode potential on both computers and mobile phones, enabling online detection of IR drop at both ends of the insulating joint to determine its proper functionality. Additionally, this device can be used to measure the normality and effectiveness of pipeline cathodic protection.

Product Cases

- First batch prodcts for for the cathode protection for the pipeline from Changan street to Zhongnanhai constructed by Beijing Gas

- Insulating joints for Sudan project ordered by CPECC

- DN400 insulating joint with OEM mode for Italy

- The biggest diameter DN1600 insulating joint in China

- DN1000 insulating joint for the water supply project of Pudong Shanghai chemical industry zone

- DN1000 PN10MPa insulating joints for West-East gas pipeline

There are no reviews yet.