Basic Feature or Parameter | |||

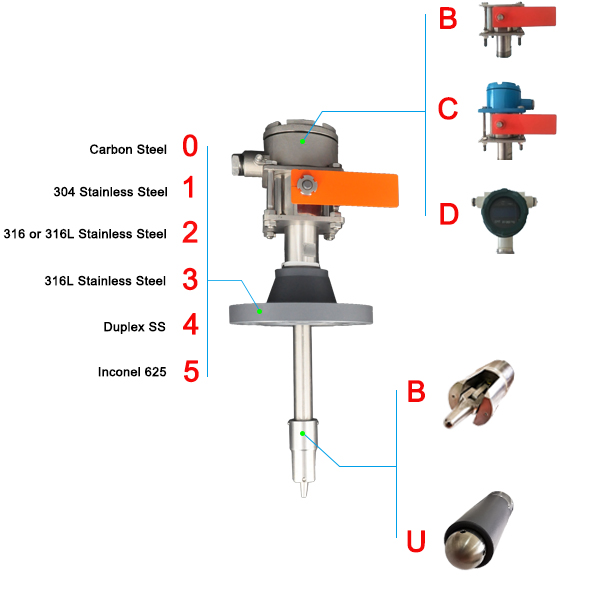

| Pig Detector Pipeline | B | C | D |

| Type | Intrusive | ||

| Indicator feature | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

| Installing type | 2″Nipple welded. Design pressure up to 10000Psi | ||

| Plug body length _Correspond to total standoff | Meet the actual needs | ||

| Operating temperature | —20~120℃/Meet customer requirements | ||

| NACE MR – 01- 75 | Yes | ||

| Ingress protection | IP65/IP66 | ||

| Explosion-proof class | ExdⅡ BT4 | ExdⅡ BT4 | |

| Include DBB valve | Yes | ||

| Remove under pressure | Yes(The whole machine comes with a simple retriever_ two whole threaded studs) | ||

Optional Feature | ||||||

| ● Standard configuration — None ○ Optional configuration | ||||||

| Trigger type (B-bi-directional/F-Bi-directional feather/U-Uni-directional*) | ○/○/● | |||||

| Trigger mechanism-Flag interaction (No/Yes_ The flexibility of the trigger mechanism would be checked online) | —/● | —/● | —/— | |||

| Internal part material (316L SS/DSS/INCONEL) | ●/○/○ | |||||

| Flange/Body material(PTFE-coated A105N/304SS/316LSS/DSS/INCONEL, As per MR) | ●/○/○/○/○/○ | |||||

| The position of the Internal liquid surface(High_Need to heating/Low_With no need for heating) | —/● | |||||

| Junction box material(Aluminium alloy/316SS) | —/— | ●/○ | ●/— | |||

| Switch type(DPDT/SPDT) | —/— | ○/● | ○/● | |||

| Switch rating(DC24V 3A/DC24V 5A) | —/— | ●/○ | ●/— | |||

| Electrical connection size (M20×1.5(F)/1/2″NPT(F)) | —/— | ●/○ | ●/— | |||

| Retriever(Two full thread studs/ special tools) | ●/○ | |||||

| Insert depth adjustment range(±10mm) | ● | |||||

| * Standard configuration of Uni-directional trigger is ball shape. | ||||||

| Corresponding relations between trigger and Insert depth (In pipe) | ||||||

| Trigger type | Bi-directional | Bi-directional feather | Uni-directional | |||

| Insert depth (In pipe) | 21mm | 30mm | 13mm | |||

Introduction to the Pig Detector Pipeline

The Pig Detector Pipeline is an essential component in the maintenance and operation of long-haul pipelines, particularly in industries where ball descaling is a routine necessity. This system is designed to accurately detect the passage of a pig at predetermined locations within the pipeline, facilitating the smooth completion of pigging operations.

Technical Characteristics of the Pig Detector

- Applicable Pressure Range: The device is suitable for pressures up to 10 Mpa.

- Temperature Suitability: It operates effectively within a temperature range of -20°C to 120°C.

- Pipe Diameter Compatibility: The system is designed for pipes with diameters starting from DN100.

- Applicable Media: It can work with non-corrosive fluids such as petroleum products and natural gas. The device is compatible with all metal pipelines that have good welding performance and are made from materials like 20# steel.

- Insertion Length: The pendulum needle, which inserts into the tube, has a length of 60 mm, ensuring effective interaction with the pig.

Types of Displays and Modes

The Pig Detector Pipeline system offers various display and signaling options:

- Field Indicating Flag (Manual Reset): This feature allows for a manual reset after the pig has passed, providing a simple visual indication.

- On-Site Digital Display: Features an LED digital display that logs the time of the pig’s passage and saves this data for later retrieval.

- Remote Signal Terminal (SPDT): With a capacity of AC380 DC220 5A, this allows for remote monitoring and control, suitable for explosion-proof installations.

Explosion-Proof and Environmental Specifications

- Explosion-Proof Rating: EXd II BT4

- Protection Class: IP66

- Corrosion Resistance: WF1

- Application Zones: Suitable for areas with explosive gas mixtures, specifically Zone 1 and Zone 2. It handles gas groups IIA and IIB, and temperature groups from T1 to T4.

Equipment Structure

The Pig Detector Pipeline system includes several key components:

- Base: Welded directly to the pipeline and made from 20# steel.

- Mounting Flange: Connects the ball valve to the base and is constructed from stainless steel for durability and corrosion resistance.

- Ball Valve: Acts as the primary component of the pressure release system.

- Pressure Release Valve: Designed to safely discharge pressure with a dual-release mechanism.

- Positioning Screws: Used for securing the device in the correct position.

- Connecting Ring: Links the mechanical body to the control unit.

- Safety Card: Provides a safety self-locking function to prevent accidental operation.

Operation of the Clock Control Watch Head

The clock control watch head, integral to the Pig Detector, is a robust, explosion-proof component that uses a 6V power supply from four 5# batteries. It features:

- LED Digital Display: Shows the current time or the time of pig passage.

- Memory and Low Power Consumption: Automatically records the time of the pig’s passage and is designed for low power consumption, allowing the batteries to last 1 to 2 years.

Usage and Maintenance

Before operation, you must activate the device by pressing the specified buttons to clear previous records and set the current time. The system is designed to remain in a low-power “sleep” state, activating only during pig passage, viewing, or time adjustment.

Disassembly and Maintenance Procedure

Disassembly requires a systematic, step-by-step process in which you remove components such as the connecting flange, positioning screws, and core to facilitate maintenance or replacement of parts like O-ring seals. You must carefully manage the pressure during disassembly to safely avoid hazards.

Conclusion

With its detailed configuration and robust design, the Pig Detector Pipeline system proves indispensable in ensuring the efficiency and safety of pipeline operations. Its precise detection capabilities and versatile display options make it suitable for a broad range of industrial applications, actively supporting effective pipeline management and maintenance activities.

There are no reviews yet.