Introduction

Pig indicators play a crucial role in modern pipeline operations. They provide real-time feedback on the location and status of pigs—tools used to maintain and inspect pipelines. These indicators are essential for ensuring the smooth functioning of pipeline maintenance tasks.

Pipeline maintenance is critical to the safety and efficiency of pipeline systems. Pigging, a key maintenance technique, involves sending a “pig” device through the pipeline. This helps in cleaning, inspecting, or repairing the pipeline from the inside. Without pigging, pipelines could face blockages or damage that remain undetected until serious issues occur.

Pig indicators enhance the effectiveness of pigging by tracking the pig’s journey throughout the pipeline. They alert operators when the pig passes certain points, ensuring that it is functioning correctly and progressing as planned. This immediate feedback is vital for preventing accidents and ensuring that maintenance tasks are completed promptly.

Moreover, by using pig indicators, operators can avoid unnecessary shutdowns and optimize maintenance schedules. This proactive approach not only saves time but also reduces costs associated with prolonged downtimes. Thus, pig indicators are indispensable tools in the arsenal of pipeline maintenance, providing essential data that helps maintain the integrity and reliability of pipeline operations.

Indicator Types

| Indicator Types | ||||

| Indicator Types | A | B | C | D |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Non-intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

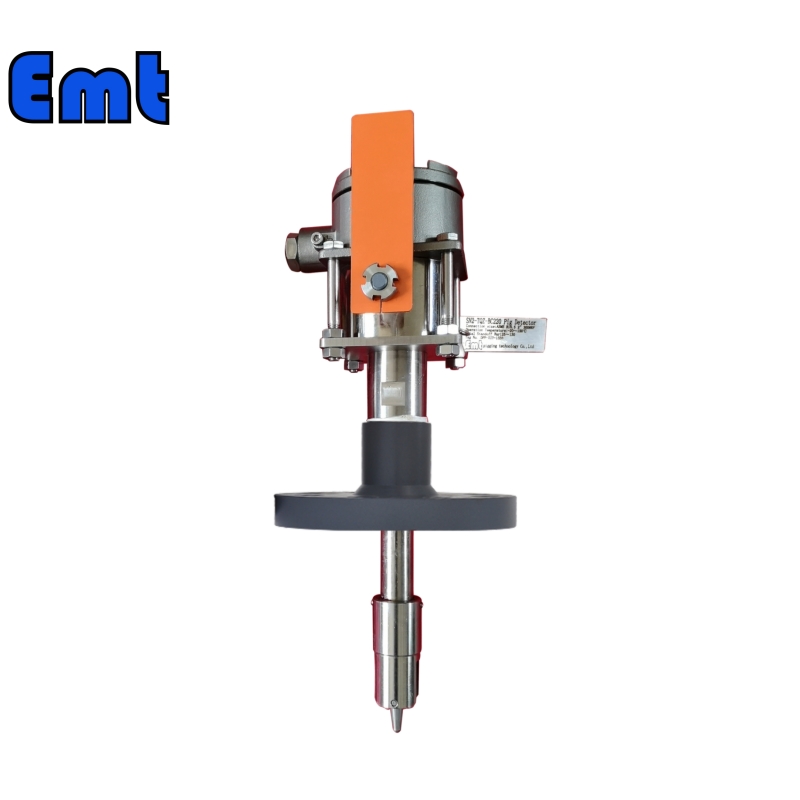

Specifications

| Name | Pig Indicator |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | —20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

| Name | Non-intrusive Pig Indicator |

| Operating Temperature | —39.8℃/80℃ |

| Operating Humidity | 41%~83% |

| Sensor Type | Magnetic Induction |

| Signal Switch Type | SPDT |

| Passing time | ±2s |

| Cleaning Pig Speed Range | 0.2-10 m/s |

| Switch Capacity | 2A |

| Reset Type | Auto Rese |

| Cable Joint Type | M20*1.5、 1/2NPT F |

| Explosion-Proof | Exd IICT6 Gb |

| IP Grade | IP65 |

Understanding Pigging in Pipeline Maintenance

What is Pipeline Pigging?

Pipeline pigging involves sending a device, known as a pig, through a pipeline. This process serves multiple purposes. Initially, it cleans the pipeline by removing debris and buildup. Additionally, it inspects for any damage or corrosion inside the pipeline. Pigging also plays a role in separating different product batches within the same pipeline. This ensures that the pipeline operates efficiently and safely, maintaining the quality and integrity of the materials transported. Thus, pigging is essential for effective pipeline maintenance and management.

The Role of Pig Indicators in Pipeline Operations

What are Pig Indicators?

Pig indicators are devices used to detect the presence of a pig within a pipeline system. They play a crucial role in monitoring and confirming the pig’s progress and location as it travels through the pipeline. Essentially, these indicators provide real-time status updates, which are vital for safe and efficient pipeline operations.

How Pig Indicators Work

Pig indicators work by sensing the pig as it passes a specific point in the pipeline. They are strategically positioned at key locations along the pipeline to ensure continuous monitoring. When a pig passes by an indicator, the device activates, sending a signal to the pipeline operators. This helps in confirming that the pigging operation is proceeding as planned without any disruptions or blockages.

The mechanics of pig indicators involve either physical, mechanical contact, or non-contact, electronic methods. Mechanical indicators may use a flag or a wheel that turns when the pig passes by. This physical change is easy to spot and indicates the pig’s passage. On the other hand, electronic indicators use sensors that can detect the pig without direct contact. These sensors often use magnetic fields or acoustic signals to identify when the pig is nearby.

Benefits of Using Pig Indicators

Enhancing Safety and Efficiency

Enhancing safety and efficiency in pipeline operations is paramount. Pig indicators play a crucial role in this process by preventing blockages and ensuring the integrity of the pipeline system. These devices help detect and address issues before they escalate into major breakdowns.

Regular use of pigging with pig indicators helps clear potential blockages early. This proactive cleaning prevents the buildup of deposits that could lead to reduced flow or even pipeline ruptures. As a result, pipelines maintain optimal operational conditions, which is essential for efficient performance.

Moreover, pig indicators contribute to the overall integrity of the pipeline. They provide vital information on the condition of the pipeline interior, allowing for timely maintenance and repairs. This ongoing assessment helps to prevent leaks and structural failures that could have severe environmental and economic impacts.

Through continuous monitoring, pig indicators also ensure that any abnormalities are detected swiftly. This immediate detection allows operators to take quick action, reducing the risk of accidents and improving safety for both workers and the surrounding communities.

There are no reviews yet.