Introduction

An intrusive pig indicator is a device that the operator should install on the pipe at a prescribed distance to detect the passage of a pig or ball. This device typically features a trigger that goes through a welded part inserted into the pipe. When a pig passes, the trigger immediately triggers the mechanism, which in turn activates the signal device.

Types of EMT Pig Indicators

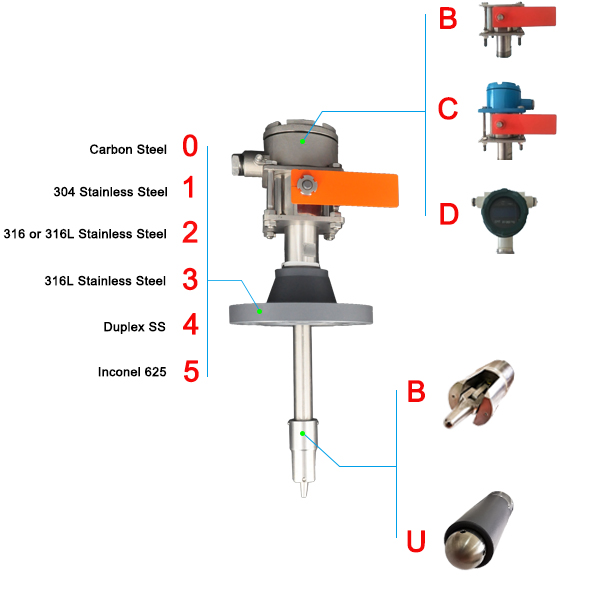

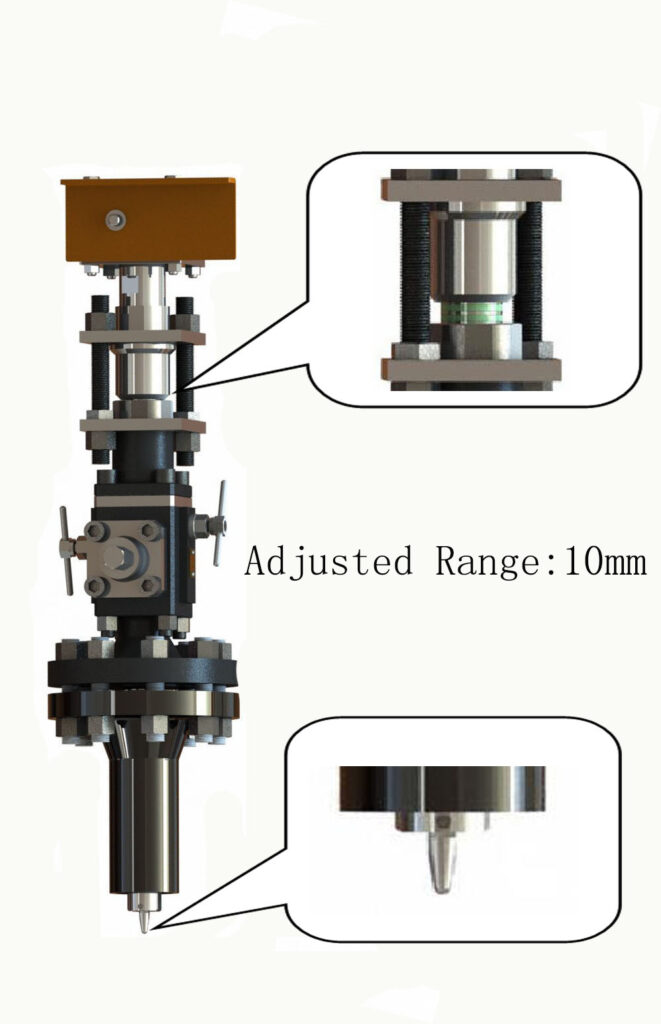

We provide different kinds of pig indicators. According to different needs, we can produce different types. For intrusive pig indicators, EMT has an adjustable type. There are 20mm and 10mm adjustable ranges to choose from. And the trigger type has two kinds: bi-directional and uni-directional.

| Indicator Types | A | B | C | D |

|  |  |  | |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Non-intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signal | Date and time display combined with electrical signal |

Security

Generally, one installs the base of the Pig Indicator on the pipeline by welding it according to the product’s instructions. To prevent damage to the O-seal ring during welding, one must remove the movement beforehand. Then, during welding, only a part of the base should be welded onto the pipeline. Do not weld the base or the movement without disassembly. If the movement is not removed and connected to the base for welding at the same time, it is very easy to damage the O-ring seal in the body at high temperatures, resulting in leakage.

Before installation, inspect the movement’s sealing ring for any notches or marks and replace it if necessary. After welding, ensure the base is flush and the inner wall is smooth. Then, using a special wrench, screw the movement into the base and adjust its direction.

Inadequate welding practices or prolonged exposure of the rubber seal to heat can damage the seal ring, leading to potential leaks at the movement’s edge, the connecting rod, or the joint. This damage could result in a complete seal failure. Regular tightness inspections are crucial for the proper operation of the Pig Indicator to avoid these issues.

Non-intrusive Pig Indicator

The indicator can mainly monitor the running condition of the pig in the long-distance pipeline operation. The pass indicator is above the pipeline. When the pig passes in the pipeline below it, the instrument will issue a photoacoustic alarm after receiving the signal. And the watch head shows that if no one is on duty, the alarm signal will remain maintained until the manual zero is cleared. The zero is the “pass” memory function of the pig through the indicator. For a 10km pipeline, place a cleaning pig every 1km. Check the indicator after a blockage to find its location. If the first and second indicators show a “through” alarm, but the third and fourth don’t, the blockage is between them. It can be determined that the location of the jam is within 1 km between the second and third pass indicators. We only need to use the positioning receiver to find it within this 1 km range, eliminating the whole search process, greatly shortening the distance of manual search, and saving manpower and time.

Before using the pass indicator, check whether the battery is sufficient. Then plug in the probe and turn on the power switch for 30 seconds to work normally. Usually, we will adjust the gain according to the conventional buried depth of the pipeline and whether the instrument has an audible and visual alarm signal. This is an important basis for correctly judging whether the pig has passed the section. 1~1.5 grid position. Because the indicator has the memory function of “passing” the pig, the reliability of the alarm signal of the indicator is closely related to the setting location and the adjustment of the gain of the instrument.

Something Needs Attention Before Use

Place the indicator before bends in the pipeline where pigs slow down. Look for uncovered or shallow pipe sections. These locations allow the probe to detect a stronger signal due to proximity to the pig. As a result, you can lower the indicator’s gain. This step effectively reduces interference and enhances alarm reliability.

Keep the indicator away from high-voltage lines and interference sources. Avoid areas near welding machines or motors that switch on and off frequently. Always adjust the gain to be as low as possible. High gain increases sensitivity to interference and the chance of false alarms.

Before sending the pig, choose the indicator locations for long-distance pipelines. Assign a person to monitor each indicator. Ensure all workers learn to use the indicator before starting. They should know how to tell useful signals from disruptive ones. Inform every worker of the pig’s launch time and speed. Duty personnel must know when the pig is likely to pass their section. They should keep a vigilant watch on the indicator’s status.

There are no reviews yet.