Introduction

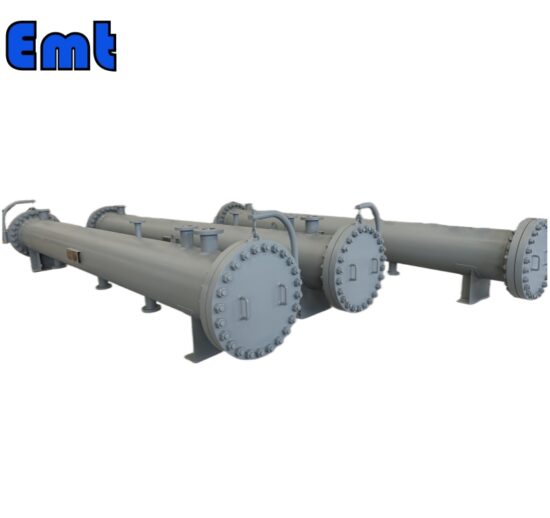

A pig launcher and receiver are installed at both ends of a pipeline and primarily consist of a cylinder, a quick-opening closure, a reducer pipe, supports, a short pipe, and other components. This setup boasts a straightforward structure that allows for rapid switching and excellent sealing performance. Additionally, its ease of operation, robust corrosion resistance, and high safety and reliability make it a preferred choice. The design and manufacturing of these devices are in accordance with the GB150 “Steel pressure vessel” standard. Depending on their application, pig launchers and receivers are categorized into two types: the PL type for launching and the PR type for receiving.

Main Datasheet of Pig Launcher and Receiver

| Design Conditions | ||

| 1. | Pipeline Size | From 6″ up to 56″ |

| 2. | Design Code | ASME VIII Div 1; ASME B31.3; ASME B31.4; ASME B31.8, etc. |

| 3. | Design Factor | 0.5, 0.6, 0.7, etc. |

| 4. | Corrosion Allowance | 0–5 mm or more |

| 5. | Design Pressure | CL150, CL300, CL600, CL900, CL1500, CL2500, or as required. |

| 6. | Design Temperature (Min/Max) | -50℃ / 200℃ |

| 7. | Closure Type | Clamp Ring Type Quick Opening Closure |

| 8. | Installation Orientation | Horizontal, Vertical, and Inclined |

| 9. | Applicable Medium | Gas, Oil, Petroleum, Chemical Materials, Water, etc. |

| Structure and Main Materials | ||

| 1. | Major Barrel/Min Barrel | ASTM A106, ASTM A516 Gr.70, or as required. |

| 2. | Quick Opening Closure (with Interlock System) | ASTM A515 Gr.70, ASTM A516 Gr.70, And ASTM A105, ASTM A350 LF2 Class1, ASTM A694 F42 F46 F48 F50 F52 F56 F60 F65 F70, or as required. |

| 3. | Sealing Ring for the Closure | Viton, Nitrile |

| 4. | Saddle Support | Q235, or as required. |

| 5. | Flange | ASTM A105, ASTM A694 F70, or as required. |

| 6. | Lifting Lug/Eyes | Q235, or as required. |

| 7. | Grounding | Yes |

| 8. | Name Plate | Stainless Steel, or as required. |

| Certificates | ||

| 1. | ASME U Stamp Certificate | Applicable |

| 2. | Third-Party Inspection | BV, SGS, ABS, DNV, or as required. |

Correct Use Requirements

The safety interlocking device installed on the quick-opening closure door cover is the key component for opening the quick-opening blind plate. The operator must read and abide by the quick-opening closure operation procedures in detail when using them to prevent accidents.

Maintenance

Always use a special wrench to open the quick-opening closure.

After every operation involving the opening of the receiver, inspect the sealing ring of the quick-opening closure for integrity. Simultaneously, clean the sealing groove to prevent impurities from damaging the sealing ring and causing leaks.

During the pig passing process, which is conducted under pressure, care must be taken to ensure the pig launcher and receiver are not subjected to hard impacts.

Installation of Pig Launcher and Receiver

To install a Pig Launcher and Receiver:

Firstly, the team responsible for installation must pour the foundation according to the designated plane layout and size of the saddle, ensuring to leave a hole for the anchor bolt to be embedded.

Next, carefully lift the receiver cylinder into its designated position and proceed with the grouting of the anchor bolts, which should be done in two stages for optimal stability.

Once the grouting sets, tighten the anchor bolts and nuts. During this step, utilize two saddle supports for the device, with one end as a sliding support. For the sliding saddle’s anchor bolts, use two nuts each. Tighten each nut, step back once, and then secure it with the second nut to lock it in place.

Following that, properly ground the saddle to ensure electrical safety.

Finally, connect each nozzle on the pig launcher and receiver to the process pipeline, completing the installation process.

Precautions during installation:

(1) Pay attention to the oil, gas inlet and outlet of the receiving cylinder relative to the left and right direction of the blind plate (from the blind plate or main line).

(2) When connecting with the process pipeline, different pipelines should not be diagonally cross-connected to prevent the pig from getting stuck.

Working Process

According to the operation process of the station.

After the pig has completed its run and collected debris, first open the blowdown valve of the pig launcher and receiver to discharge any remaining oil and gas in the cylinder. Next, open the vent of the quick-opening closure. Once the pressure inside the launcher and receiver is fully relieved, proceed to open the quick-opening closure. Finally, clean out the oil and gas residue in the pig launcher and receiver to prepare for the next pipeline cleaning operation.

Operation of Pig Launcher and Receiver

The operation of a pig launcher and receiver may vary based on the specific pigging system in use. However, in most cases, the process includes the following steps:

- Pig Launcher:

After production, the pipeline operator should close the main feed valve. They open the launcher’s limit bar and use a push rod to push the pig into the pipeline. If the system is for liquids, they should close the air vent valve and open the intake valve to allow compressed air into the launcher. They then slowly introduce compressed air into the launcher until the pressure reaches a certain level, generally not exceeding 0.2 MPa, preparing the pig for launch. They regulate the flow of compressed air to maintain a steady speed of the pig in the pipeline, recovering the product. - Pig Receiver:

For the pig receiver, they should slowly introduce compressed air to pressurize it. The main outlet valve at the receiver’s end must be closed. Next, they open the ground valve on the inlet pipeline of the launcher. The pig is pushed into the pipeline by compressed air from the receiver. Once the pig reaches the launcher, they should close the limit bar to secure the pig inside the launcher. The pig does not need to be removed unless it is for maintenance or replacement.

Pig launchers and receivers are critical components of pipeline pigging systems. Hanhaifeng provides its customers with high-quality and reliable pig launchers and receivers for both independent and integrated process automation systems.

There are no reviews yet.