1. Introduction to Intrusive Pig Signal Indicator

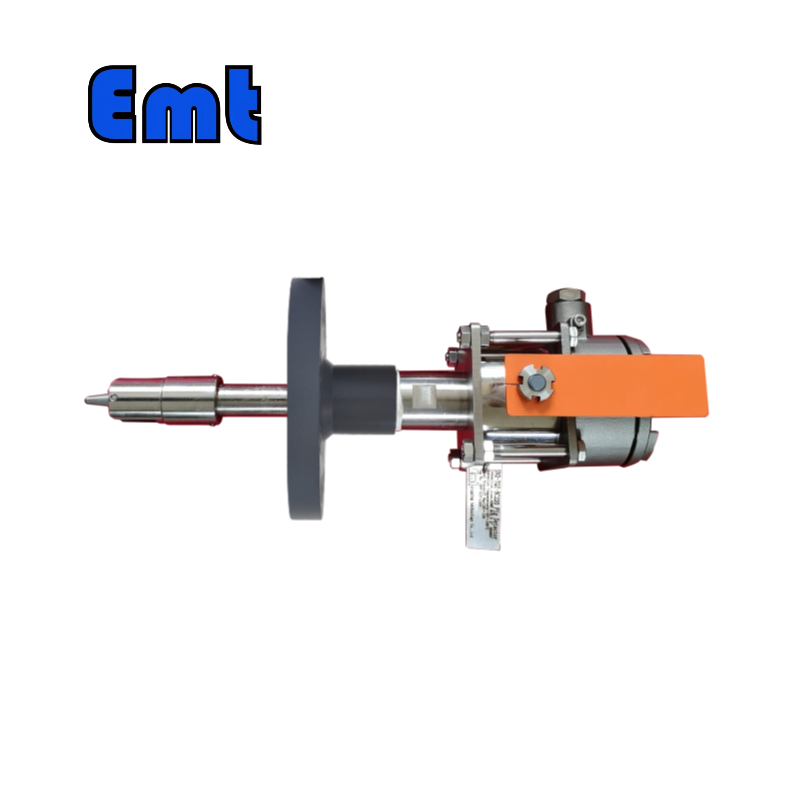

Pig Signal Indicator is designed for the critical task of detecting the passage of pigs or spheres within pipelines. These devices are installed directly onto the pipeline and feature a trigger mechanism that penetrates the pipe wall, allowing for direct interaction with the pig as it passes by. The primary purpose of an intrusive pig indicator is to provide a clear and immediate signal to the operator, indicating that the pig has passed a specific point in the pipeline system. This helps in coordinating maintenance activities and verifying the pigging process.

2. Types of EMT Pig Indicators

EMT offers a comprehensive range of pig indicators to suit various pipeline configurations and operational requirements. Our portfolio includes different types of intrusive pig indicators, each with unique features to accommodate the specific needs of your pipeline monitoring process.

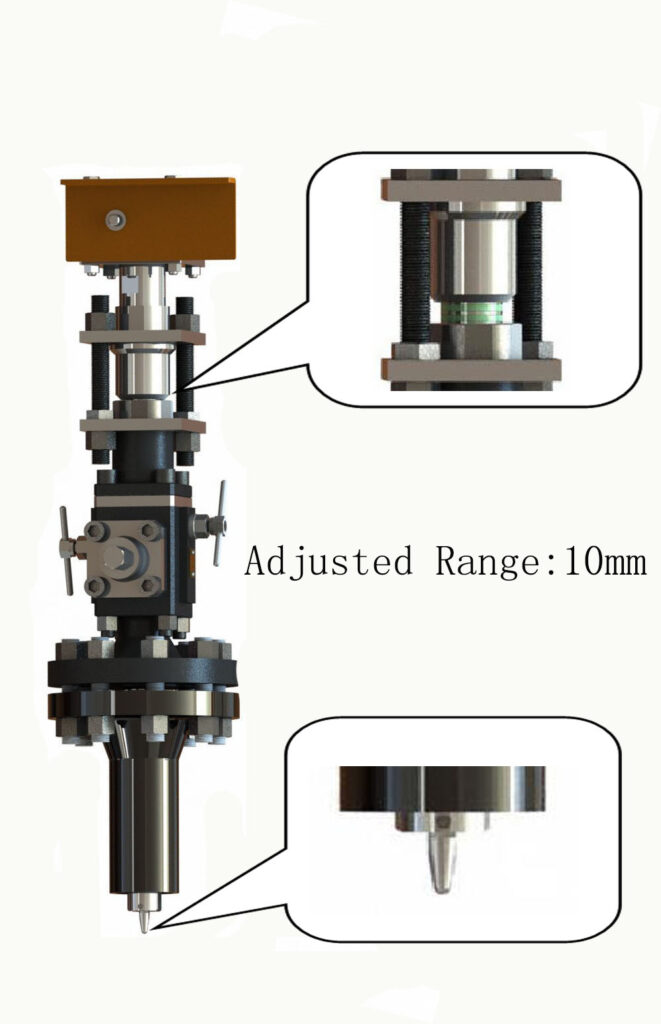

The adjustable intrusive pig indicators by EMT are particularly versatile, offering adjustable ranges of 20mm and 10mm to ensure precise positioning within the pipeline. This adjustability is critical for accommodating variations in pipe wall thickness and pig sizes.

Our indicators come equipped with two main types of trigger mechanisms: bi-directional, which can detect pigs traveling in either direction within the pipeline, and uni-directional, which is designed to detect pigs moving in a single direction. The choice between these mechanisms will depend on the specifics of your pipeline operation and the nature of the pigging tasks being performed.

3. Indicator Features and Types

EMT’s pig indicators are available in four main types, each with distinct features:

| Indicator Types | A | B | C | D |

|---|---|---|---|---|

| Intrusive Type | Intrusive | Intrusive | Intrusive | Non-intrusive |

| Indicator Features | Popper Type | Manual Reset Flag | Manual Reset Flag with Electrical Signal | Date and Time Display with Electrical Signal |

The intrusive models, including types A, B, and C, are designed for direct installation onto the pipeline and feature reliable signaling mechanisms such as popper type and manual reset flags. Type C goes a step further by integrating an electrical signal output, allowing for remote monitoring and signaling capabilities.

Type D, the non-intrusive model, offers the advantage of external installation with a date and time display combined with an electrical signal output. This feature-rich model provides a comprehensive monitoring solution without the need for pipeline penetration, making it ideal for scenarios where maintaining pipe integrity is paramount.

Each of these indicators is crafted with precision to ensure reliable performance under the demanding conditions of pipeline operations. Whether you require the simplicity of a popper type indicator or the advanced capabilities of an electrical signal output with date and time display, EMT has a solution that will fit your pipeline pigging needs seamlessly.

4. Installation and Security of Pig Signal Indicator

Proper installation of pig indicators is vital for the safety and functionality of the pigging operation. EMT Pigging provides clear guidelines to ensure that pig indicators are installed correctly:

Preparation for Installation:

Before the welding process begins, it is crucial to remove the mechanical parts, or ‘movement,’ from the pig indicator to protect the O-ring from heat damage. Damage to the O-ring can compromise the seal and lead to leaks, so this step is essential for maintaining the integrity of the device.

Welding and Inspection:

After removing the movement, weld only the base part onto the pipeline as per the product’s instructions. Post-welding, inspect the sealing ring for any damage, such as notches or marks, and replace it if necessary. Ensuring that the base is flush with the pipeline and the inner wall is smooth will facilitate the correct function of the indicator.

Reassembly and Adjustment:

Once the welding is complete and the area has cooled, reassemble the indicator by securing the movement back into the base using a specialized wrench. At this point, adjust the direction of the movement to align with the expected path of the pig.

5. Maintenance and Operational Security

Maintenance of pig indicators is essential to prevent leaks and ensure their proper function:

Regular Welding Checks:

Inadequate welding can lead to leaks. It is important to conduct regular inspections of the welds to ensure they remain secure and intact.

Tightness Inspections:

Regular tightness inspections are a must to avoid leaks at the movement’s edge, the connecting rod, or the joint. Such leaks can result in a complete failure of the seal, so maintaining the seal’s integrity is a key aspect of operational security.

6. Non-intrusive Pig Indicator Functionality

Non-intrusive pig indicators are vital tools for monitoring the progress of pigs in pipeline pigging operations:

Monitoring and Alarms:

These indicators are designed to monitor the pig’s progress without the need for direct contact with the pipeline interior. When a pig passes beneath the indicator, the device will emit an audible and visual alarm, thanks to its photoacoustic signaling technology. The indicator’s display will also retain the time and date of the pig’s passage, utilizing a “pass” memory function, which is especially useful when there is no personnel on duty.

Strategic Placement for Blockage Detection:

For effective monitoring, place cleaning pigs at intervals along the pipeline, such as every 1km for a 10km pipeline. After a suspected blockage, checking the indicators will help locate the blockage. For example, if the first two indicators signal ‘pass’ but the third and fourth do not, the blockage is likely between the second and third indicators. This approach narrows down the search area significantly, saving both time and resources.

In summary, the proper installation and maintenance of pig indicators are critical for the safe and effective operation of pipeline pigging. Regular checks and inspections are essential to prevent any potential leaks or malfunctions. Non-intrusive pig indicators offer a convenient and reliable way to monitor pigging operations and quickly identify blockages, enhancing the overall efficiency of the pipeline maintenance process. EMT Pigging’s range of pig indicators, with their robust construction and advanced features, provide operators with the tools needed for secure and efficient pipeline management.

7. Preparation and Attention Before Use

Prior to deploying pig indicators, a thorough pre-use check is essential to ensure that the device will function as expected:

Battery and Probe Connection Checks:

Confirm that the battery is fully charged and properly installed. A sufficient power supply is critical for the operation of non-intrusive pig indicators. Additionally, verify that the probe is securely connected, as this is vital for the accurate transmission of signals.

Gain Setting Adjustments:

The gain setting is a crucial adjustment that should be tailored to the pipeline’s burial depth and the anticipated distance from the pig to the indicator. A correct gain setting ensures that the alarm signal is both reliable and discernible from any background noise.

Memory Function Check:

The memory function of the pig indicator is a key feature that contributes to the reliability of the alarm signal. It retains a record of the pig’s passage, which is essential for later verification, especially in remote or unmanned locations.

8. Optimal Placement and Usage Tips

Strategic placement of pig indicators is necessary to optimize their effectiveness:

Placement Before Bends and Shallow Sections:

Positioning indicators before pipeline bends or in sections where the pipeline is shallow increases the likelihood of detecting the pig. These locations typically allow for a stronger signal as the pig slows down and comes closer to the surface.

Avoiding Interference:

To minimize potential signal interference, keep pig indicators away from high-voltage power lines and sources of electromagnetic interference, such as welding machines or frequently switched motors. Adjust the gain as low as possible to reduce the sensitivity to interference while still capturing the pig’s signal.

Monitoring Long-Distance Pipelines:

For extended pipelines, assign personnel to monitor each indicator and provide them with comprehensive training on distinguishing between valid signals and interference. Inform all relevant parties of the expected pig launch times and velocities to ensure that the monitoring personnel are alert and ready to observe the indicator’s status when the pig is projected to pass their section.

9. Conclusion

In closing, EMT Pigging’s Pig Signal Indicator is indispensable for conducting efficient and secure pipeline pigging operations. They offer operators the assurance of accurate and reliable pig tracking, essential for maintaining pipeline integrity and performance.

As a final note, remember the importance of proper preparation, strategic placement, and attentive monitoring when using pig indicators. These practices are key to maximizing the utility of EMT Pigging’s sophisticated pig tracking technology and ensuring the smooth operation of your pigging activities. By following these guidelines, you can confidently rely on EMT Pigging’s Pig Indicators for effective pipeline maintenance and management.

There are no reviews yet.