Understanding Pipeline Pig

Definition and Purpose of Pipeline Pigs

Pipeline pigs are tools that service pipelines from the inside. They clean, inspect, and maintain these critical infrastructures. They essentially ensure that pipelines operate smoothly and efficiently.

Importance of Pipeline Maintenance and Cleaning

Regular maintenance prevents pipeline failures and environmental hazards. It also ensures the safe transport of materials. Cleaning with pigs removes buildup and blockages, crucial for maintaining flow.

Role of Pipeline Pigs in Ensuring Operational Efficiency and Integrity

Pipeline pigs play a key role in enhancing operational efficiency. They help avoid costly downtimes by ensuring the pipeline is free from obstructions. Furthermore, they maintain the structural integrity of the pipeline, preventing leaks and ruptures. Thus, they are vital for the long-term reliability and safety of pipeline operations. As a result, using pipeline pigs translates into significant cost savings and operational success.

Introduction

Brief Overview of the Pipeline Industry

The pipeline industry plays a crucial role in the global economy, facilitating the efficient transportation of energy resources like oil and gas. This sector continuously evolves, integrating advanced technologies to enhance safety and efficiency.

Introduction to EMT

EMT, initially a modest venture, has grown into a prominent scientific and technological development enterprise. Since its inception, EMT has committed to innovation and prioritizing customer needs. The company has successfully developed the LCQZ series of electronic pigs, SN series of dosing devices, and a variety of pressure-level transmitters. These innovations find extensive applications across petroleum, electric power, chemical, and machinery industries.

Notably, products like the LCQZ series have earned long-standing recognition at major sites like Daqing and Liaohe Oilfields. Building on domestic success, EMT established Emt Piping Technology Co., Ltd., to spearhead international market expansion. This strategic move paid off as our products now reach over 50 countries, gaining acclaim and fostering lasting partnerships with numerous overseas oil companies.

For over three decades, EMT has remained dedicated to the piping equipment manufacturing industry, focusing on technological advancements. We continue to embrace the principle of aligning our efforts with customer demands and technological innovation, aiming for mutual benefit and shared prosperity with partners worldwide.

Types of Pipeline Pig

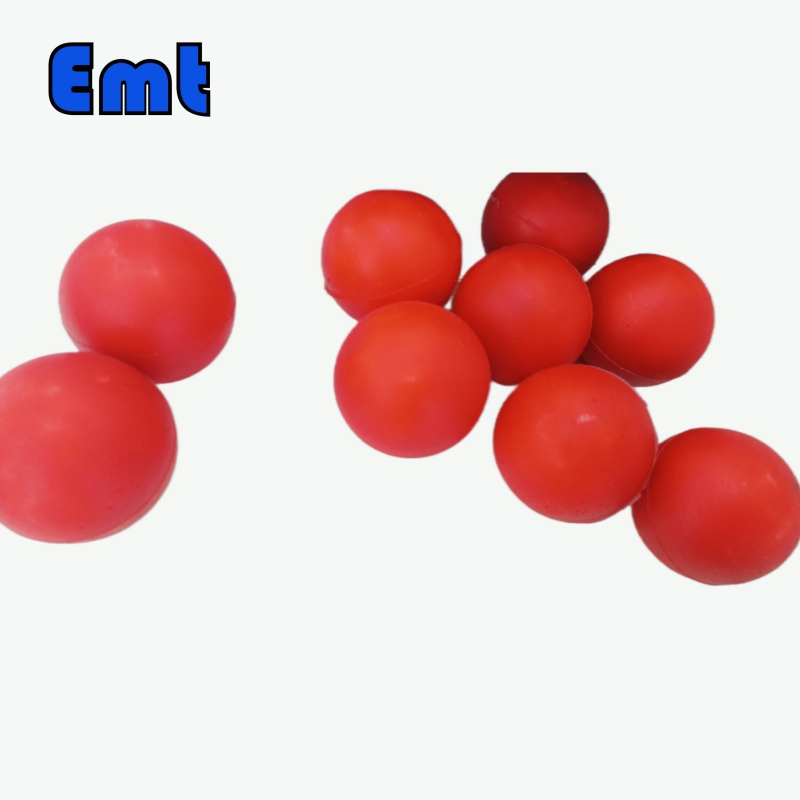

Solid Cast Polyurethane Pig

Features and Benefits of Solid-Cast Polyurethane Pigs

Solid-cast polyurethane pigs are durable and resistant to wear. They offer excellent sealing capabilities, which enhance their cleaning efficiency. Their robust design allows for repeated use in harsh conditions.

Applications in Pipeline Cleaning and Inspection

These pigs are ideal for removing tough deposits and scale from pipelines. They also serve well in inspection roles, helping identify pipeline integrity issues.

Foam Polyurethane Pig

Features and Benefits of Foam Polyurethane Pigs

Foam polyurethane pigs are flexible and lightweight. They easily navigate bends and uneven pipeline sections. This type’s adaptability makes it suitable for a variety of pipeline diameters.

Applications in Pipeline Dewatering and Product Separation

These pigs excel in dewatering tasks, effectively removing water to prevent corrosion. They are also used for product separation, helping to isolate different fluids transported in the same pipeline.

Other Types of Pipeline Pigs (e.g., Steel Pigs, Brush Pigs, etc.)

Overview of Alternative Materials and Designs

Steel pigs are tough and handle high-pressure environments well. Brush pigs, equipped with brushes or scrapers, are specialized for mechanical cleaning. Each type offers unique features tailored to specific tasks.

Applications and Considerations for Different Pig Types

Choosing the right pig type depends on the pipeline’s condition, the material being transported, and the specific cleaning needs. Steel pigs are great for heavy-duty cleaning, while brush pigs are better for removing rust and debris. Operators must consider these factors to ensure optimal pipeline maintenance and operation.

Benefits of Using EMT’s Pipeline Pig

A. Enhanced Pipeline Cleaning and Maintenance

EMT’s pipeline pigs excel in removing debris and residues. This thorough cleaning prevents clogs and corrosion. Regular use ensures pipelines remain in optimal condition.

B. Improved Operational Efficiency and Product Quality

Using EMT’s pigs boosts the flow rate and purity of transported materials. This results in fewer operational hitches and higher product quality. Efficient cleaning also reduces the need for frequent shutdowns.

C. Extended Pipeline Lifespan and Reduced Maintenance Costs

EMT’s pigs help extend the life of pipelines by preventing wear and tear. This reduction in degradation leads to lower maintenance costs over time. Additionally, the extended lifespan of the pipeline means fewer frequent replacements, saving money and resources.

There are no reviews yet.