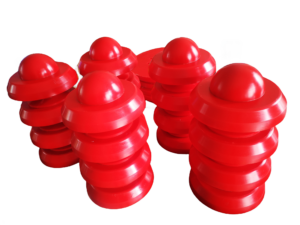

Introduction of Solid Cast Pipeline Pig

A solid-cast pipeline pig serves a crucial role in pipeline maintenance. They’re made of tough materials like polyurethane, ensuring longevity and reliability. Their solid construction allows them to withstand the harsh conditions inside pipelines.

These pigs excel at cleaning and preserving pipe interiors. They remove debris, prevent deposits, and ensure efficient fluid flow. Their design enables them to navigate complex pipeline structures, maintaining system integrity and performance.

Types and Functions of Solid Cast Pigs

Cup-Type Solid Cast Pigs: These pigs clean pipes from 4 to 56 inches in diameter. They feature durable polyurethane elastomers, offering flexibility and long-lasting rear thrust. Additionally, they have a low shutdown risk. Operators can fit adjustable measurement plates for pipeline inspection.

Disc-Type Solid Cast Pigs: These flexible pigs can house a stable mandrel. Lightweight, they range from 2 to 48 inches in size. Ideally, they clean pipes, separate fluids, and navigate tight 1D elbows with ease.

Combination Cup-and-Disc Type Solid Cast Pigs: These pigs merge cup-and-disc advantages. They provide top-notch sealing and effectively clear gases or liquids. Use them for batching, hydrostatic tests, and removing pipeline deposits like paraffin and dirt.

Pipeline Construction

Long-distance pipelines always work for a long time without stopping. Therefore, there will be much debris in it. The debris will cause a low flow speed in the conveying mediums. It can even result in corrosion and blockage. So, it is very important to check and clean the pipe regularly. Pipeline pigs are very useful in cleaning long-distance pipelines. Why do we call them pigs? Because when the pigs work, their harsh and unpleasant sounds are like the pigs’ voices. The pig name is still in use today.

Pipeline cleaning depends on these pigs. The air, liquid, or other conveying mediums in pipes push pigs forward. Pigs can clean up crude oil and debris in the pipe and reduce the damage of inner wall corrosion. Besides, they can also check whether there are deformations in the pipe.

Brief Introduction to Pipe Cleaning

You can see pipe cleaning technology as a specific area of material handling and cleaning technologies. Theoretical research is based on theoretical discoveries in the fields of tribology, friction, lubrication, and wear. The general definition of pigging is the propulsive activity of pipes through movable pigs that perform certain actions within pipes.

In the late 19th century, oil industries used pigging in their pipes. Starting around 1970, the chemical industry introduced more precise cleaning and sealing of pigs. The first industrial pigging equipment came. People improved the pigs as a plug with a diameter that interfered with the inner diameter of the pipe. People mainly used this equipment to remove impurities from pipes. In addition to the pig, it also needs to be matched with other components. Such as the associated pipes, valves, and control systems.

The Pigging Method and Selection Method of Long-Distance Natural Gas Pipeline Application

1) Wax-containing crude oil pipeline pigging program

After a certain period of using wax-containing crude oil pipelines, oil wax deposits on the gas pipeline walls. When the oil wax is deposited at a certain thickness, it is necessary to pig the gas pipeline. This can reduce the cost of the gas pipeline in operation and increase its throughput. Suitable soft pigs and mechanical pigs that can carry tracking devices should be selected when performing wax cleaning and pipe cleaning. In the pigging operation, the first step is to use a soft pig to understand the specific situation inside the pipe. After ensuring that there is no problem in the pipeline, the mechanical pig is used to do the pigging work. The mechanical pig can piggle the foreign matter in the gas pipeline. It can also use its steel brush to remove wax from the pipe wall and corrosion from rust and scale.

2) Pigging method for a gas pipeline application

Gas in natural gas pipelines usually contains gases such as carbon dioxide and hydrogen sulfide. These gases will combine with water to form hydrates, leading to the blockage of natural gas pipelines and equipment. This will pose a hidden threat to the safety of natural gas pipelines. The traditional pig is selected to do the pigging operation of the gas pipeline, which is put into operation. For example, the use of a cup pig for the transport of moisture in the gas pipeline. Its main job is to remove water from the pipeline. At this time, we must use a very good-sealing straight pig to clean. If it is a gas pipeline from a reservoir or gas field, the pipeline will contain light hydrocarbons and other condensates. We use straight pigs directly for cleaning.

3) Pigging method of natural gas pipeline for mixed transportation of oil, gas, and water

In the long-term use of a long-distance natural gas pipeline, the accumulation of liquid in the pipeline and the corrosion of the inner wall will occur during the long-term operation of the two-phase flow pipeline. These fluids accumulate at low points in the pipeline, resulting in an increased pressure drop in the pipeline and a reduced flow area in the pipeline. The efficiency of transporting natural gas will also be reduced.

The factors that affect the pigging effect in the two-phase flow pipeline are:

The mixture of gas and liquid passes through the gas pipeline at a flow rate and pressure drop that permits movement;

The gas-liquid ratio in the pipeline, the shape of the pipeline profile, The amount of fluid accumulated in the pipeline; The size of the liquid stopper trap instrument;

In an offshore pipeline system, the height between the bottom of the riser and the stopper trap instrument;

The commonly used pigging method for two-phase flow pipelines is to use a general pig ball and pig to deal with it. Pigging can also be performed using a pig with a bypass.

Conclusion

In summary, solid-cast pipeline pigs are essential for maintenance. They ensure clean, efficient pipelines. Different types offer varied benefits. Regular pigging prevents blockages and corrosion. This maintains safety and optimizes flow. Besides pigs, we also provide other pipe-cleaning equipment and corrosion monitoring systems.

There are no reviews yet.