EMT is proud to introduce the Pipeline Scraper Foam Pig, a versatile and essential tool in pipeline maintenance and cleaning. This product, designed with precision, offers a comprehensive solution for a variety of pipeline conditions and requirements, ensuring optimal cleanliness and function.

Name | Customized Pipeline Scraper Foam Pig | ||||

Material | Polyurethane | ||||

Light Density | 0.02-0.3g/m3 | ||||

Medium Density | 0.08-0.12g/m3 | ||||

Heavy Density | 0.13-0.16g/m3 | ||||

Feature | 1. High wear resistance | ||||

2. Good cleaning performance | |||||

3. Low cost | |||||

Payment | TT/LC | ||||

Advantage | 1. They are lightweight and flexible. | ||||

2. Nice cleaning efficiency. | |||||

3. Accurate location tracking. | |||||

Material Specifications of Pipeline Scraper Foam Pig

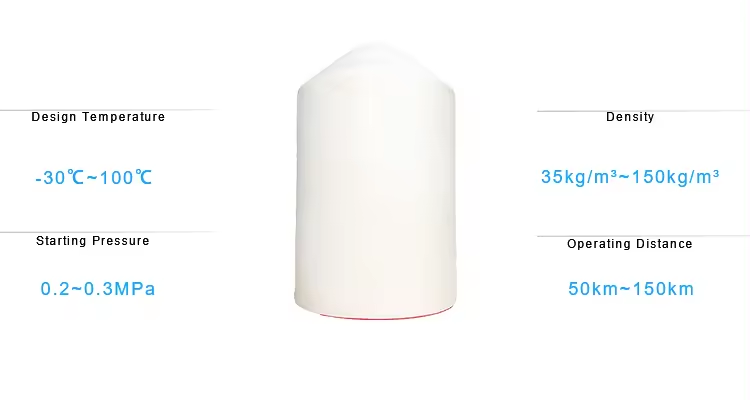

Constructed from polyurethane foam available in low, medium, and high densities, the EMT Pipeline Scraper Foam Pig is tailored to match the specific needs of various pipeline applications. These densities range from 35 kg/m³ for light density, up to 150 kg/m³ for high density, providing a range of mechanical strengths and wear resistance suitable for different pipeline conditions.

Operational Efficiency of Pipeline Scraper Foam Pig

The EMT Pipeline Scraper Foam Pig is not only effective but also highly efficient. It operates within a temperature range of -30°C to 100°C and can maintain functionality over impressive distances, making it suitable for long pipelines like the Central Asia Natural Gas Pipeline. Furthermore, it supports pressures up to 7 MPa and can navigate pipelines with a minimum bend radius of 3D, where D is the outer diameter of the pipe.

Basic Parameter

| Name | Model | Performance | Technical Parameters |

Hygroscopic Foam Pig

| LCQZ-RTH | 1. It is formed by one-time foaming of polyether polyurethane material.2. Soft texture, and good elasticity. 3. It has strong water absorption performance. And the deformation amount can reach 70%. 4. Remarkable effect on dewatering, degreasing, and drying of pipelines. | Starting pressure: 0.2-0.3 MPaDensity: 35 kg/m³~150 kg/m³ Withstand pressure: 7 MPa Stretch rate: 320% Compression ratio: 60 Flex life: 50,000 times Attrition rate: 4 mm/100 km Operating distance: 50 km~150 km Operating temperature: -30℃~100℃ |

Bare Foam Pig | LCQZ-RTN | 1. Soft texture and good flexibility.2. With strong water absorption, the deformation amount can reach 60%. 3. Used for dewatering, cleaning, and drying pipelines. | Starting pressure: 0.02 MPaDensity: 35 kg/m³~220 kg/m³ Withstand pressure: 7 MPa Stretch rate: 320% Compression ratio: 60 Flex life: 50,000 times Attrition rate: 4 mm/100 km Operating distance: 50 km~150 km Operating temperature: -30℃~100℃ |

Polly Foam Pig | LCQZ-RTR | 1. Its interior is foamed by polyurethane material. The surface is coated with a polyurethane elastomer coating.2. Good flexibility and certain wear resistance. 3. The deformation amount can reach 50%. Which is the most widely used foam pig. 4. Used for scrubbing, descaling, and fluid isolation of pipes. | Starting pressure: 0.02 MPaDensity: 35 kg/m³~220 kg/m³ Withstand pressure: 7 MPa Stretch rate: 320% Compression ratio: 50 Flex life: 50,000 times Attrition rate: 2 mm/100 km Operating distance: 100 km~300 km Operating temperature: -30℃~100℃ |

Crisscross Foam Pig | LCQZ-RTCC | 1. The interior is foamed by polyurethane material. And the surface is covered with a prismatic block polyurethane elastomer.2. High surface hardness and large friction coefficient. 3. Has high elasticity and toughness. 4. Used for pipeline cleaning, cleaning, and cleaning impurities. | |

Crisscross Foam Pig With Brush | LCQZ-RTCB | 1. The interior is foamed by polyurethane material. And the surface is coated with an elastomer coating.2. Paste the spiral wire brush. 3. The deformation amount can reach 40%. Which is both elastic and will not fall off. 4. It is used to remove the hard scale of the pipeline and has better rust removal and decontamination effects. | Starting pressure: 0.02 MPaDensity: 35 kg/m³~220 kg/m³ Withstand pressure: 7 MPa Stretch rate: 320% Compression ratio: 50 Flex life: 50,000 times Attrition rate: 2 mm/100 km Operating distance: 100 km~300 km Operating temperature: -30℃~100℃ |

Safety of Pipeline Scraper Foam Pig

In line with EMT’s commitment to safety and environmental stewardship, the Pipeline Scraper Foam Pig includes features designed to minimize environmental impact. For instance, it assists in the drying of gas transmission pipelines, crucial after pressure testing and pigging to ensure safe and efficient pipeline operation.

Application of Pipeline Scraper Foam Pig

The EMT Pipeline Scraper Foam Pig excels in versatility. Primarily, it is used for sweeping pipelines and cleaning various impurities post-construction and pre-commissioning. Additionally, this tool is indispensable for exhausting gases prior to hydrostatic testing and for dewatering post-testing. It effectively checks for roundness errors, ensures accurate valve positions, and can even remove weld flash at joint locations.

Moreover, the Scraper Foam Pig is regularly or irregularly employed to discharge ash, remove paraffin, descale, and treat water in used oil and gas pipelines. It also serves a dual function as an inflator of different fluid mediums during pipeline operations. Furthermore, it is adept at applying anticorrosive coatings to pipeline walls, enhancing their longevity and durability.

Polyurethane material specification:

| NO. | Factory inspection main indicators | Cup/DISC |

| 1 | 20℃Hardness(SHORE A) | 85±2 |

| 2 | Tensile strength (MPa) | 51.7 |

| 3 | 100%stress at definite elongation (MPa) | 4.8 |

| 4 | 300%stress at definite elongation (MPa) | 9.2 |

| 5 | Tensile set (%) | 780 |

| 6 | Tear strength (KN/m) | 73.0 |

| 7 | Impact resilience (%) | 32 |

| 8 | DIN abrasion (mm²) | 35 |

There are no reviews yet.