Introduction

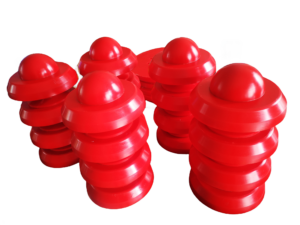

The Polly-Pig, crafted from open-cell polyurethane foam in varying densities, is coated externally in different materials tailored to specific uses. While each pig is designed for a particular function, many can be adapted based on user preference within certain limits. These pigs are shaped in bullet form to help navigate through fittings and valves and are available with concave ends for use in either direction. To prevent tumbling, the length of a Polly-Pig is typically twice that of its diameter. They are intentionally sized to be slightly larger than the pipeline’s internal diameter, creating necessary friction against the pipe walls for effective cleaning. Custom sizing is available to meet any specific pipeline requirements.

Poly pigs navigate through pipelines, ensuring the smooth operation of crucial infrastructures that transport oil, gas, and water. These devices play a pivotal role in preventing disruptions and maintaining flow efficiency, making them invaluable in the energy sector.

What are Poly Pigs?

Poly pigs, short for polyurethane pigs, are tools designed for pipeline cleaning and inspection. Constructed from flexible polyurethane foam, they can fit snugly within pipes, adjusting to varying diameters and bends. Their design allows for the addition of abrasives or coatings tailored to specific cleaning tasks, making them a versatile choice for pipeline operators.

How Poly Pigs Clean Pipelines

Inserted into pipelines, poly pigs use the existing pressure of the fluid or gas to traverse the system. As they journey through, their textured surfaces scrape away rust, scale, and other accumulations. This process not only cleans but also inspects the inner walls of pipes for potential issues, such as cracks or buildup, alerting maintenance teams to areas in need of repair.

Benefits

Employing poly pigs offers significant benefits, such as reducing the need for costly shutdowns due to blockages or maintenance. By regularly clearing out debris, poly pigs ensure the purity of the materials transported, crucial in industries where contamination can lead to severe consequences. Additionally, their use prolongs the operational lifespan of pipelines by preventing the corrosive effects of debris buildup, saving companies from premature replacement expenses.

Advantages of Pigs in Various Scenarios

Foam pigs excel in various pipeline maintenance scenarios due to their lightweight and flexible nature. They’re particularly effective in pipelines with multiple bends or diameter changes where rigid pigs might become stuck or cause damage. Foam pigs also provide a gentle cleaning action suitable for pipelines that require a non-abrasive touch, such as those in the food and beverage industry or water treatment facilities. Their adaptability ensures they can navigate through uncleaned or irregularly shaped pipelines, offering a reliable cleaning solution across a broad range of conditions.

Parameters

Name | Poly Pig | ||||

Material | Polyurethane | ||||

Light Density | 0.02-0.3g/m3 | ||||

Medium Density | 0.08-0.12g/m3 | ||||

Heavy Density | 0.13-0.16g/m3 | ||||

Feature | 1. High wear resistance | ||||

2. Good cleaning performance | |||||

3. Low cost | |||||

Payment | TT/LC | ||||

Advantage | 1. They are lightweight and flexible. | ||||

2. Nice cleaning efficiency. | |||||

3. Accurate location tracking. | |||||

Frequently Asked Questions

How long do poly pigs last?

The lifespan of a poly pig varies depending on its use. For a single cleaning run, a foam pig may last just once, while more durable pigs can withstand multiple uses. Factors like pipeline condition, distance traveled, and type of debris affect longevity.

Can poly pigs be used in all types of pipelines?

Poly pigs are versatile but not one-size-fits-all. They work in many pipelines, including oil, gas, and water. However, compatibility depends on the pipeline material, diameter, and the nature of the product being transported.

What are the signs that a pipeline needs pigging?

Signs include reduced flow rate, increased pressure differential, and product contamination. Regular maintenance schedules also dictate the need for pigging, regardless of immediate signs.

How do I know which type of poly pig to use?

Choose based on pipeline features and cleaning requirements. Foam pigs suit light cleaning and drying, while solid pigs are for heavy-duty tasks. Consider the advice of a pigging specialist for specific operations.

Can poly pigs damage a pipeline?

If properly selected and used, poly pigs should not damage pipelines. Incorrectly sized pigs or those with inappropriate abrasiveness can cause damage, so it’s crucial to match the pig to the pipeline’s specifications.

How often should pipelines be pigged with poly pigs?

Frequency depends on several factors, including the type of product transported, pipeline conditions, and regulatory requirements. Some may need pigging monthly, while others might require less frequent maintenance.

Are poly pigs environmentally friendly?

Poly pigs themselves are environmentally benign when used correctly. They do not emit pollutants during the cleaning process, and many companies are adopting biodegradable pigs to further reduce environmental impact.

What happens if a poly pig gets stuck in the pipeline?

A stuck pig requires immediate attention. Techniques to free it include increasing line pressure, using a bypass method, or, in extreme cases, cutting the pipeline. Prevention is key, so always ensure the pig is compatible with the pipeline’s size and the product flow.

Conclusion

Poly pigs are essential for maintaining the efficiency and integrity of pipelines across various industries. These adaptable cleaning tools, made from polyurethane foam, cater to different conditions within pipelines, preventing costly blockages and contamination. The appropriate selection and use of poly pigs, guided by industry best practices, ensure minimal environmental impact and maintain pipeline health. As technology progresses, the design and functionality of poly pigs will continue to advance, further enhancing their role as a key component in the sustainable operation and longevity of critical pipeline infrastructures.

There are no reviews yet.