Introduction

A Quick Closure is a fast-opening device. It fits the round openings on pressure vessels. It generally consists of a cylinder flange, head cover, hook ring or clamp, sealing ring, safety interlock mechanism, opening and closing mechanism, swing arm, and a short section when needed.

Quick Closures are a type of quick-opening manhole cover for pressure vessels. They are widely used in natural gas facilities that require frequent opening and closing. Quick Closures serve to clean and clear pipelines and to inspect and clean containers. They are fixed quick-opening devices set at the pipe mouth. Quick closures are standard on filter separators and pig launchers.

Common types of Quick Closures include lock ring, clamped, buckled, expansion ring, and fixed pressure ring structures, with most operations done by hand. The pigging process involves valve switching to allow media into the station after launching and receiving the pig. The pig launcher needs proper installation to suit worker operations and ensure safety. It must have a safety valve installed.

Technical Specifications

- Nominal Diameter (DN): <1800mm

- Design pressure (PN): ≤40 MPa

- Working Medium: oil, gas, water

- Design Temperature: -50℃~300℃

- Material: 16Mn,A350LF2, A105, SS304, SS316, F51, F53, F55, INCONEL625, HASTELLOY C

- Pipe Thickness: 6mm~100mm

Working Principle

The rotating part of the Quick Closure aligns with the sealing part, using the inclined plane of the catch plate to generate forward axial thrust. This pushes the blind plate forward, causing the sealing ring to compress and seal. This design prevents any wear and tear on the seal. The interlock locks securely and reliably. The closure must lock in place; (otherwise, the safety interlock mechanism cannot be inserted). Once the safety interlock is in place, the head cover cannot rotate; after system venting, open the safety interlock first. This releases all internal pressure before opening the head cover; otherwise, it won’t open.

Quick Closure Design

The main structures include the drive mechanism, a three-segment clamp locking mechanism, a safety interlock mechanism, a centering device, a swing arm, a head cover, a cylinder flange, and an LCD display-type pressure sensor. The outer circumference where the head cover and the cylinder flange meet has a protrusion with a right-angle trapezoidal cross-section. An annular clamp with a trapezoidal groove on the inner circumference fits around the outer circumference of the head cover and cylinder flange. The annular clamp consists of three 120-degree arc-shaped clamps hinged together: left, right, and bottom segments. The drive mechanism enlarges or reduces the inner diameter of the three-segment clamp. The head cover rotates along the axis of the swing arm to achieve quick opening and closing of the blind plate.

Things need to pay attention

Before opening a Quick Closure, inspect it and its accessories for good condition. Confirm the status of all valves before opening the blind plate. To operate, first vent the natural gas inside the pig launcher to ensure it’s not under pressure. The pressure indicator should read zero. Keep the vent valve fully open and prepare specialized tools.

Do not perform Quick Closure operations facing active human areas. For larger pigging operations, set up receiving and sending devices to reduce labor intensity. Pigging barrels for launching and receiving pigs are vital parts of pigging and sweeping equipment. They are installed at the ends of pipelines for this purpose. They have a coaxial double plate and a sliding seal.

Understanding Quick Closure Mechanisms

Structure Features

The Quick Closure’s safety and its rapid opening and closing are key features and research focuses of this equipment. Its reliability and safety manifest in two aspects. One concerns safety in the closed position under working pressure. The equipment’s static strength design ensures this, with the main pressure-bearing components made from 16MnIII forged steel. The software SW6 checks the strength. The other aspect concerns safety during opening. The design includes a safety interlock mechanism with self-locking, shock resistance, and anti-loosening features. It also allows for secondary pressure relief during the opening. This not only prevents the Quick Closure from loosening during locking but also avoids the danger of opening under pressure.

Quick Opening Closures are divided into vertical and horizontal installations. Mainly used in petrochemical, natural gas pipeline, pressure vessel equipment. EMT has a strong technical development and research force. It also has advanced production equipment and perfect testing means at home and abroad. We work with enthusiasm to provide customers with high quality mature products and perfect after-sales service.

Types of Quick Closure Systems

Lock Ring Closure

Closure Structure

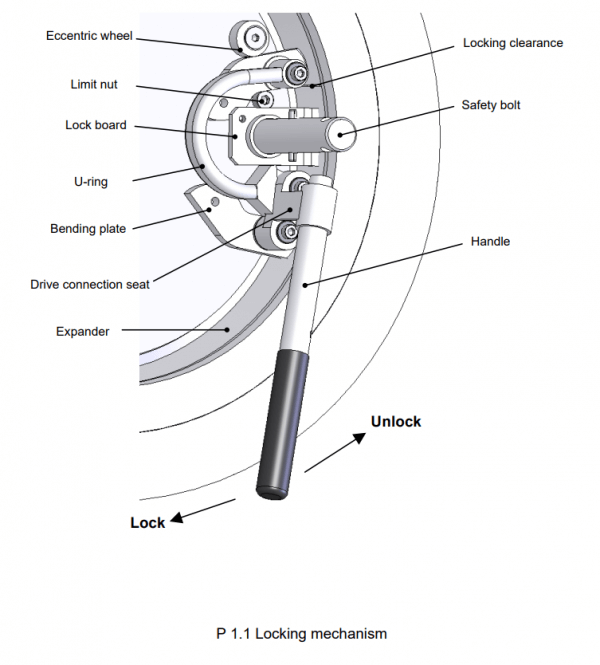

The Lock Board ensures safety. You must not dismantle the lock board or turn the handle before removing the safety bolt. A crank-slider mechanism operates the lock ring expansion device. Turning the operating handle moves the connected guide post along an arc-shaped slot, altering the lock block’s distance. This action adjusts the lock ring’s circumference, allowing it to stretch or compress within the groove. Clockwise handle rotation draws the lock block in, pressing it against the lock ring groove and securing the closure flange door. Turning the handle counterclockwise pushes the lock block out, disengaging the lock ring from the groove and releasing the closure flange door.

Sealing Principle

Reliable seal. The seal adopts an O-ring self-tightening sealing structure. It can meet the frequent opening and closing conditions. There is no relative rotation between the sealing ring and the sealing surface, and the sealing ring is not easy to damage. Thus the sealing system is better protected. The O-ring adopts fluorine rubber integral extrusion to ensure the service life.

Safety Equipment

Clamp Closure

Product characteristics

1. Check that the indicators on the container are normal.

2. Check that the connecting parts of the container and the quick-opening blind plate should not leak;

3. Necessary explosion-proof tools, fire extinguishers, fire MATS and other facilities are ready;

4. The operation of opening and closing the blind plate shall be carried out by one person and supervised by other personnel;

5. During the opening and closing operation, the front of the quick-opening closure cannot stand.

Opening steps

1. Check the pressure in the chamber of the blind plate cylinder. If the pressure indicates that the value is not returned to zero, no operation is allowed

2. Check whether the container inlet and outlet valve is completely closed without any source of pressure

3. Slowly loosen the pressure alarm bolt and check whether there is pressure in the container

4. If there is no pressure, remove the pressure alarm bolt and its locking disc from the blind plate

5. Turn the handle 60-120 degrees counterclockwise to start the drive chain and the mechanical device to open the closure

Bayonet Closure

Bayonet Type Quick Closure Technical Performance

- The self-locking feature prevents the Quick Closure from loosening during the locking process and from being opened under pressure.

- The seal ring does not rotate against the sealing surface, reducing damage and protecting the sealing system.

- The three-segment clamp locks simultaneously and evenly, shortening the screw length and making switching more flexible.

- The design increases the bite area (over 90%) for use in high-pressure, large-diameter gas pipelines, with main pressure-bearing components made from 20# or 16Mn forged steel without welded parts.

Opening process

(1) Open the vent valve and exhaust valve of the container installed by the closure, so that the pressure in the container is reduced to zero. Unscrew the interlock mechanism.

(2) Turn the lead screw with a wrench, so that the inner diameter of the three-lobe locking ring gradually becomes larger, so that the inner diameter of the locking ring is greater than the outer diameter of the blind plate cover to stop rotating the lead screw. The locking ring is separated from the closure seat and cover.

(3) Pull the handle with your hand to open the closure.

Specifications

1) Design pressure: DN1.6-9.99Mpa.

2) Design temperature: 40℃.

3) Test pressure: water pressure is 1.5 times the design pressure.

4) Nominal diameter: DN100-DN1400.

5) Corrosion margin: 2mm.

6) Earthquake rupture: 7 degrees.

7) Applicable medium: natural gas.

8) Service life: 30 years.

Conclusion

In conclusion, Quick Closures offer essential safety and efficiency. They ensure fast and reliable access to pressure vessels, crucial in natural gas applications. Specifically, their design accommodates frequent use with minimal wear. Moreover, safety interlocks and operational procedures protect against accidental openings. Importantly, regular inspections and pressure checks are mandatory. Ultimately, with proper maintenance and operation, Quick Closures provide a durable solution for pipeline management, boasting a service life of up to 30 years.

There are no reviews yet.