Знакомство

Иглы для впрыска химикатов имеют решающее значение для добавления химических веществ в трубопроводы высокого давления в нефтегазовой промышленности. Они помогают обеспечить бесперебойную работу оборудования и продлить срок службы. Операторы используют эти иглы для подачи важных химических веществ, таких как метанол, в поток масла. Это предотвращает образование ледяных гидратов и поддерживает хорошую работу нефтяных скважин.

Эти иглы плотно прилегают к трубопроводам, чтобы избежать утечек даже при высоком давлении. У них есть специальный насос для точного добавления химикатов или отбора проб. Наша команда экспертов всегда готова помочь вам понять и выбрать правильные перья для ваших нужд.

Выбор режима игл для впрыска химикатов EMT

| Модель | ||||||||||||||||||||||||||||

| СИ | Фитинг для доступа к иглам для впрыска химикатов | |||||||||||||||||||||||||||

| -Код | Затычка | |||||||||||||||||||||||||||

| Пх | Тип | Материал | Уплотнительный материал | |||||||||||||||||||||||||

| 0 | Нет запроса | 0 | КС | 0 | Нет запроса | |||||||||||||||||||||||

| 1 | Корпус полой свечи | 1 | 316SS | 3 | СХД | 1 | Уплотнительное кольцо из витона / первичная набивка из ПТФЭ | |||||||||||||||||||||

| 2 | Прочный корпус вилки | 2 | 316ЛСС | 4 | ИНКОНЕЛЬ | 2 | HNBR | |||||||||||||||||||||

| Код | Инжекторная гайка | |||||||||||||||||||||||||||

| Нхх | Размер соединения | Материал | ||||||||||||||||||||||||||

| 0 | т.е. нет запроса | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | т.е. 1/4" | 1 | т.е. 316SS | 3 | т.е. DSS | |||||||||||||||||||||||

| 2 | т.е. 1/2" | 2 | т.е. 316LSS | 4 | т.е. ИНКОНЕЛЬ | |||||||||||||||||||||||

| –Код | Инъекционная трубка | |||||||||||||||||||||||||||

| Схх-Лк" | Размер соединения | Материал | Сопло | Размер линии (x") | ||||||||||||||||||||||||

| 0 | Нет запроса | 0 | КС | 0 | т.е. нет запроса | Наиболее эффективное положение для впрыска обычно находится в центре трубы | ||||||||||||||||||||||

| 1 | т.е. 1/4" | 1 | т.е. 316SS | 1 | т.е. открытый | |||||||||||||||||||||||

| 2 | т.е. 1/2" | 2 | т.е. 316LSS | 2 | т.е. перо | |||||||||||||||||||||||

| 3 | т.е. DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | т.е. ИНКОНЕЛЬ | |||||||||||||||||||||||||||

| –Код | Ниппель и клапан (или концевой фланец) тройника | |||||||||||||||||||||||||||

| Тхх | Размер соединения | Материал | ||||||||||||||||||||||||||

| 0 | т.е. нет запроса | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | т.е. соска 1/4" | a | т.е. 1/4"ниппель и клапан | 1 | т.е. 316SS | |||||||||||||||||||||||

| 2 | т.е. 1/2"Ниппель | b | т.е. 1/2"ниппель и клапан | 2 | т.е. 316LSS | |||||||||||||||||||||||

| 3 | т.е. 3/4"Ниппель | c | т.е. ниппель и клапан 3/4" | 3 | т.е. Д СС | |||||||||||||||||||||||

| 4 | т.е. 1"Сосок | d | т.е. 1"Ниппель и клапан | 4 | т.е. ИНКОНЕЛЬ | |||||||||||||||||||||||

| 5 | т.е. фланец 1/4 дюйма | e | т.е. фланец с концом ниппеля 1/4 дюйма | |||||||||||||||||||||||||

| 6 | т.е. фланец 1/2 дюйма | f | т.е. фланец с концом ниппеля 1/2" | |||||||||||||||||||||||||

| 7 | т.е. фланец 3/4"Фланец | g | т.е. фланец с ниппельным концом 3/4 дюйма | |||||||||||||||||||||||||

| 8 | т.е. фланец 1"Фланец | h | т.е. фланец с концом ниппеля 1 дюйм | |||||||||||||||||||||||||

P221: например, прочный корпус заглушки в уплотнительном кольце из витона 316LSS и первичной упаковке из ПТФЭ N12: например, размер соединения инжекторной гайки составляет 1/4 дюйма, а материал - 316LSS, S122: например, впрыск Размер соединения трубки составляет 1/4 дюйма, а материал - 316LSS. Тип насадки – иглы L4":Для трубы 4". T22: Размер соединения ниппеля тройника 1/2 дюйма, материал ниппеля 316LSS | ||||||||||||||||||||||||||||

Параметры игл для впрыска химикатов EMT

Имя | Фитинг для доступа к иглам для впрыска химикатов | |

| Материал | Нержавеющая сталь 304, Нержавеющая сталь 316, DSS F51, Углеродистая сталь A105N, а также Инконель 625 | |

| Рабочая температура | -20~+120°C | |

| Функции | Во-первых, он прост в эксплуатации | |

| Во-вторых, долгий срок службы и высокая точность | ||

| Наконец, низкая стоимость и высокая эффективность | ||

| Уплата | ТТ/ЛК | |

| Преимущества | Во-первых, легкий и гибкий | |

| Во-вторых, отличная эффективность впрыска | ||

| Наконец-то точное отслеживание местоположения |

Типы сопел для впрыска химических игл

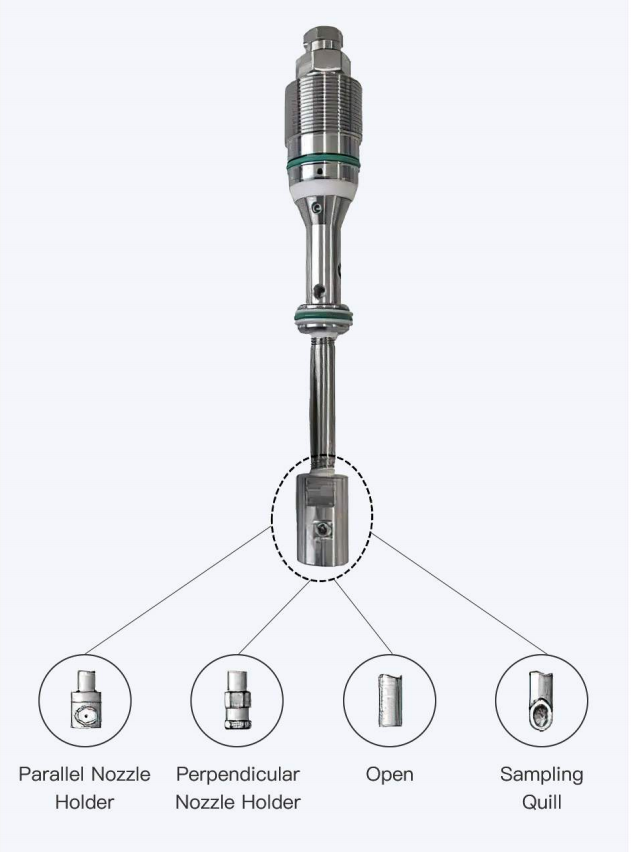

Иглы для впрыска химикатов оснащены четырьмя форсунками, предназначенными для различных задач. Параллельная форсунка впрыскивает химические вещества непосредственно в соответствии с потоком, мгновенно смешивая их. В отличие от этого, перпендикулярная форсунка распыляет химикаты поперек потока для лучшего перемешивания. Открытая форсунка позволяет химическим веществам свободно поступать в поток, удовлетворяя потребности больших объемов. Наконец, перо для отбора проб отбирает пробы трубопровода, необходимые для проверки качества.

Применение химических игл для литья под давлением

Иглы для впрыска химикатов впрыскивают химикаты в трубопроводы для предотвращения коррозии. Они помогают предотвратить засорение, поддерживая трубы в чистоте. Иглы равномерно перемешивают химикаты в протекающие вещества в трубах. Они также защищают стенки трубопроводов от агрессивных химических веществ. Вы можете использовать иглы для добавления химических веществ для защиты от замерзания, таких как метанол. Они обеспечивают бесперебойную работу в нефте- и газопроводах. Иглы помогают в контролируемом дозировании химикатов для оптимизации процессов. Они имеют решающее значение для поддержания качества и безопасности трубопроводных систем.

Предотвращение коррозии

Нефтегазовая промышленность: Иглы доставляют ингибиторы коррозии непосредственно в трубопроводы, предотвращая ржавчину и обеспечивая долговечность инфраструктуры.

Очистка воды: В линиях транспортировки воды в иглы добавляются антикоррозионные агенты для защиты от деградации труб.

Очистка трубопроводов

Нефтехимические заводы: Впрыскивая растворители и моющие средства, иглы помогают растворять и вытеснять отложения, поддерживая четкие линии для транспортировки продукта.

Очистка сточных вод: Иглы вводят чистящие средства для предотвращения засорения и поддержания эффективности потока в системах управления отходами.

Химическое смешивание

Химическое производство: Иглы используются для точного дозирования и тщательного смешивания реагентов в технологических потоках.

Продукты питания и напитки: Они обеспечивают равномерное распределение консервантов или добавок в линейках продуктов.

Защита оборудования

Нефтеперерабатывающие заводы: Иглы впрыскивают нейтрализующие химикаты для защиты оборудования от кислотных или едких веществ.

Фармацевтические препараты: Они добавляют буферные агенты в технологические линии для поддержания целостности оборудования и чистоты продукции.

Защита от замерзания

Трубопроводы природного газа: метанол или этиленгликоль впрыскиваются для предотвращения образования гидратов в холодном климате, обеспечивая свободный поток газа.

Морская промышленность: Химические антифризы вводятся в системы, которые подвергаются воздействию отрицательных температур для предотвращения обледенения.

Оптимизация процессов

Экстракция масла: Точное дозирование химикатов помогает отделить масло от других веществ, улучшая процесс экстракции.

Очистка воды: Иглы добавляют точное количество дезинфицирующих средств для очистки питьевой воды, оптимизируя очистку.

Обеспечение качества и безопасности

Выработка электроэнергии: Они поддерживают химический состав воды в котлах, обеспечивая безопасность и эффективность.

Аэрокосмическая и автомобильная промышленность: Иглы впрыскивают определенные химические вещества в топливные или смазочные трубопроводы для поддержания качества и производительности двигателей.

Отзывов пока нет.