Introduction of Our Cleaning Pigs

At EMT, we provide various kinds of Pipeline Cleaning Pigs. We are committed to providing our customers with the best products and services. Cleaning pigs are made from a soft, squishy foam material that can easily bend and twist. This makes them great for cleaning inside pipes that have lots of turns, angles, and different shapes, even when the pipes get smaller or have special parts like valves. EMT prioritizes quality above all else, understanding it’s the cornerstone of our operations. Our good name is invaluable, and that’s why we’re committed to earning your trust through diligent work. We aim to provide service that’s not only approachable but also beneficial, ensuring that your requirements are consistently understood and fulfilled.

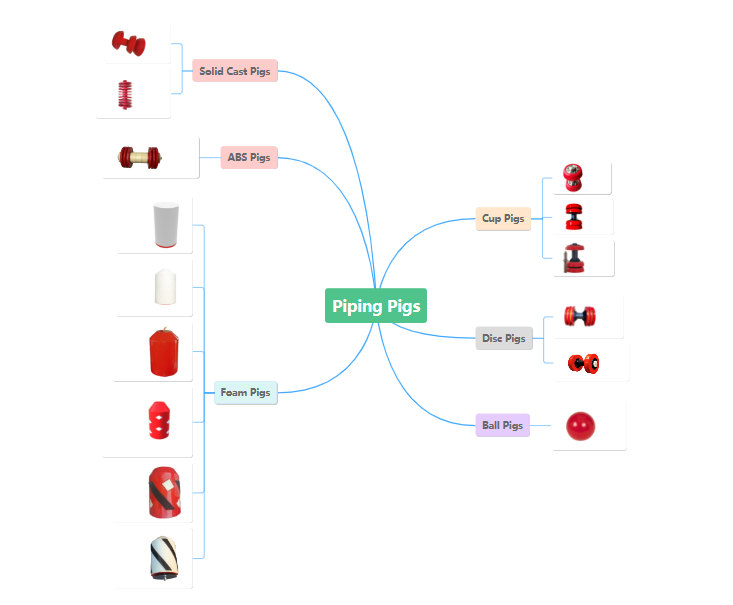

Types of Cleaning Pigs

We provide all these pipeline pigs, solid cast cleaning pigs, ABS pigs, foam pigs, cup pigs, disc pigs, and ball pigs.

Our company has developed a detachable model of solid-cast cleaning pigs, allowing separate replacement of the cup if it becomes damaged.

For foam pigs, there are different densities. Bare foam pigs are usually of low or middle density. Polly foam pigs are always of middle and high density. Some of them can add brushes, which can increase the efficiency of cleaning the pipeline. Criss-cross foam pigs are another kind of pig. It can not only absorb the water but also clean up the debris in the pipes.

For cup pigs and disc pigs, they can add many accessories. Like wire brushes, gauging discs, spring steel brushes, magnetic steel, transmitters, guide plates, and gaskets. The size of the cup ranges from 2 inches to 60 inches. If you need other sizes, please contact our EMT team. We will give you the best solution according to our years of experience.

Also known as sphere pigs, ball pigs can clean pipes effectively. Manufacturers use the highest-quality open-cell polyurethane foam to make ball pigs. Their flexibility lets them navigate short-radius bends easily. If the pipe bore unexpectedly reduces, ball pigs make an excellent choice for cleaning.

Sales Situation

For oil and gas pipeline cleaning applications, disc pigs and cup pigs are leading sales, indicating their high effectiveness and preference in the industry.

For oil and gas pipeline cleaning applications, disc pigs and cup pigs are leading sales, indicating their high effectiveness and preference in the industry.

In the removal of polyethylene wax, polyurethane pigs are showing strong sales, demonstrating their efficiency and demand in this specific cleaning application.

Applications of Cleaning Pigs

Cleaning:

Pipeline pigs maintain pipeline efficiency by actively removing debris such as scale, rust, and sediment. They scrape and sweep away unwanted materials as they travel through the pipeline, preventing blockages and ensuring a clear path for product flow.

Inspection:

Often called ‘smart pigs,’ inspection pigs carry technologies like magnetic flux leakage (MFL) tools or ultrasonic sensors. They collect data on pipe conditions, including wall thickness and corrosion, as they move through the pipeline, enabling proactive maintenance and repairs.

Drying:

Operators send drying pigs through pipelines after hydrostatic testing or cleaning to remove any lingering moisture. This step is critical, especially in gas pipelines, as water can cause hydrate formation or corrosion. Made typically of foam, these pigs work with drying agents to achieve a completely dry pipeline.

Wax Removal:

Pigs designed for wax removal tackle wax deposition in crude oil pipelines. They cut and scrape accumulated wax from the pipeline walls, ensuring free-flowing oil and reducing the risk of blockages.

Sealing and Testing:

Operators use pigs to isolate pipeline sections for safety or maintenance, creating a temporary seal. They also incorporate these pigs into pressure testing to confirm pipeline integrity. These pigs work alongside testing equipment to check that pipelines can handle the required pressure without leaks.

Функции

Pipeline pigs are made from a soft, squishy foam material that can easily bend and twist. This makes them great for cleaning inside pipes that have lots of turns, angles, and different shapes, even when the pipes get smaller or have special parts like valves.

Flexibility: They navigate through complex pipeline configurations, including tight bends and valves.

Variety of Materials: Manufacturers produce pigs from various materials, such as foam, polyurethane, or rubber, to match different cleaning needs.

Scraping and Brushing: Many pigs feature scraping edges or brushes to actively remove deposits from pipe walls.

Modular Design: Some pigs have a modular design, allowing operators to replace or add parts to meet specific cleaning requirements.

Inline Inspection Capability: Some pigs come equipped with sensors that inspect the pipeline from the inside while cleaning.

Sealing Elements: These pigs often include cups or discs that seal against the pipe wall, aiding in the effective removal of liquids and debris.

Заключение

In conclusion, cleaning pigs are indispensable tools in the maintenance and operation of pipelines. With their flexibility to navigate complex pipelines, a variety of materials to suit different tasks, and additional components for enhanced cleaning, these pigs ensure that pipelines remain efficient and safe for transport and processing. Whether for routine cleaning, detailed internal inspections, moisture removal, wax buildup prevention, or sealing for testing, cleaning pigs offer a cost-effective and reliable solution. Our extensive range of solid cast, foam, cup, disc, and ball pigs, along with the customizable options and added accessories, demonstrates our commitment to providing comprehensive pipeline cleaning and maintenance solutions tailored to the specific needs of our clients.

Отзывов пока нет.