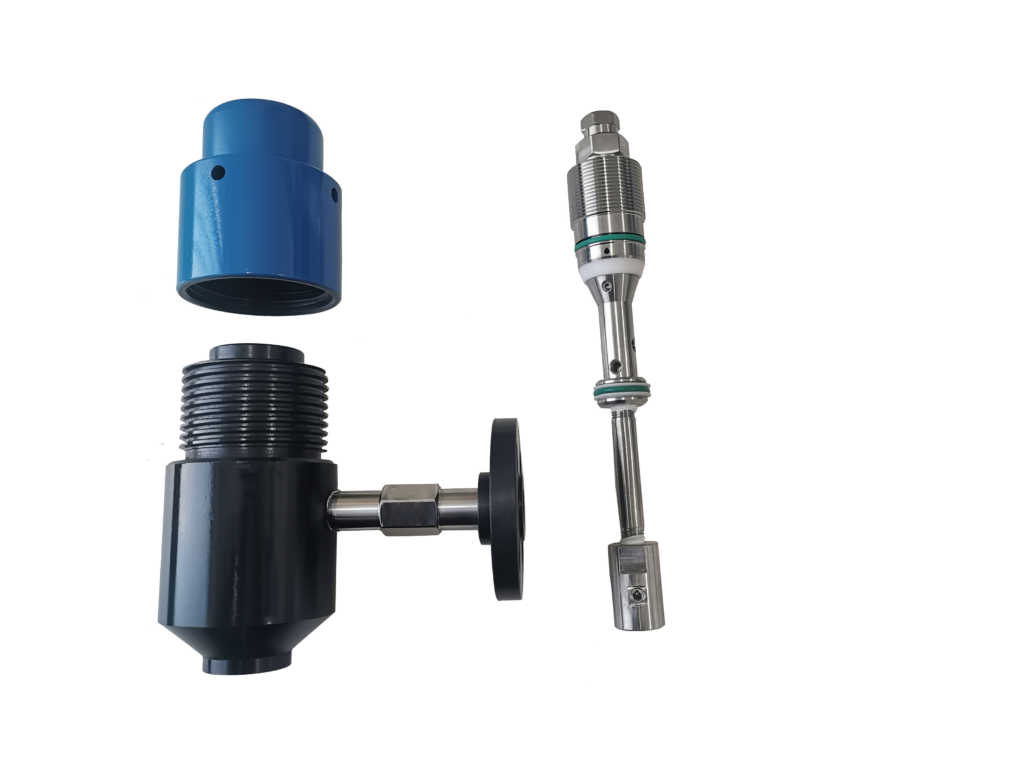

The EMT Injection Quill in Piping is an indispensable component for conducting thorough inspections and effective cleaning of pipelines. This device is integral to both the chemical injection system and the medium sampling system in piping maintenance protocols.

Utilizing the EMT Injection System, operators can inject chemical inhibitors with ease and precision. These inhibitors are crucial for minimizing or controlling corrosion within the pipeline. The system’s design allows for secure injection under operating pressure, ensuring safety and reliability.

Data sheet

Имя | High Pressure Pipeline Chemical Injection Sampling System | ||||

Материал | Нержавеющая сталь 304、Нержавеющая сталь 316、DSS F51、Углеродистая сталь A105N、Инконель 625 | ||||

Рабочая температура | -20-+120 | ||||

Особенность | 1. Простота в эксплуатации | ||||

2. Высокая точность, долгий срок службы | |||||

3. Высокая эффективность, низкая стоимость | |||||

Уплата | ТТ/ЛК | ||||

Преимущество | 1. Они легкие и гибкие. | ||||

2. Хорошая эффективность впрыска. | |||||

3. Точное отслеживание местоположения. | |||||

Featuring a variety of nozzles, the chemical injection quill is tailored to meet different application needs. Its operation is akin to that of the sampler, offering comparable functionality and convenient integration into existing systems.

Installation options are versatile, with mounting types including a 2″ flange, 2″ Flareweld access fitting, and a 1″ Nipple to NPT ball valve, catering to a range of pipeline specifications. The EMT Injection Quill is designed to withstand extreme conditions, operating effectively within a temperature range of -20 ℃ to 150 ℃ and a pressure rating of up to 6000 PSI or matching the specified flange size.

Crafted from durable materials such as Stainless Steel 304, Stainless Steel 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625, the quill promises a long life of high efficiency and accuracy, all at a low operational cost.

Преимущества

The advantages of using the EMT Injection Quill include its lightweight and flexible construction, exceptional injection efficiency, and precise location tracking. The device’s design features clear lines, insulation, high strength, and resistance to deformation and bending, ensuring easy installation and maintenance.

For payment, EMT accepts both TT and LC, accommodating various business preferences. When it comes to transport, options include air and sea. Collaborating with numerous express companies allows for the selection of a courier service that offers both speed and cost-effectiveness.

Moreover, Shenyang’s proximity to Dalian Port means that inland transportation costs are negligible, and the shipping time is significantly reduced. This strategic location, coupled with our strong partnerships with various express companies, guarantees the fastest delivery times and lowest shipping costs for our clients.

In summary, the EMT Injection Quill is an essential tool for maintaining the integrity and performance of industrial pipelines, combining ease of operation, high accuracy, and efficiency with the flexibility and resilience required for the challenging conditions of pipeline maintenance.

The chemical injection quill plays a vital role in maintaining the integrity and efficiency of industrial piping systems. Its necessity and applications can be delineated as follows:

Necessity of Chemical Injection Quill:

1. Corrosion Control:

The quill enables the precise injection of corrosion inhibitors directly into the pipeline flow, which helps prevent the internal surfaces from deteriorating.

2. Scale Prevention:

By injecting scale inhibitors, the quill helps prevent the formation of mineral deposits that can obstruct flow and reduce efficiency.

3. Biocide Delivery:

To prevent bacterial growth such as sulfate-reducing bacteria, which can cause microbiologically influenced corrosion (MIC), biocides can be introduced through the quill.

4. Operational Consistency:

Chemical injection quills ensure that the chemicals are evenly dispersed into the flowing medium, promoting consistent reactions and preventing localized high concentrations that can lead to piping damage.

5.Safety and Environmental Protection:

Proper chemical management within the system reduces the risk of leaks and spills that can be harmful to both personnel and the environment.

Applications of Chemical Injection Quill:

1. Oil and Gas Industry:

In the upstream sector, quills are used to inject chemicals that reduce the viscosity of crude oil, facilitate flow, and prevent blockages in pipelines and wellbore.

2. Refineries and Petrochemical Plants:

Here, quills inject a variety of process chemicals to protect and optimize the refining process.

3. Water Treatment Facilities:

Injection quills introduce chlorine or other disinfectants to purify water, control biological growth, and manage the pH levels.

4. Power Generation:

In power plants, especially those using steam, the quills inject amines and oxygen scavengers to control corrosion in boilers and steam lines.

5. Chemical Manufacturing:

Various process chemicals are injected for reactions, quality control, and equipment protection.

6. Food and Beverage Industry:

Quills can inject cleaning agents and sanitizers to ensure pipeline hygiene and product quality.

Overall, the chemical injection quill is an essential tool for the precise delivery of chemicals within industrial pipelines, ensuring the longevity of the infrastructure, the quality of the products transported, and adherence to safety and environmental standards.

Why Choose us

2. Samples will be offered to attest to the quality and our services.

3. The fastest feedback!

4. The fastest delivery time.

5.24 hours,7 days online.

Отзывов пока нет.