Знакомство

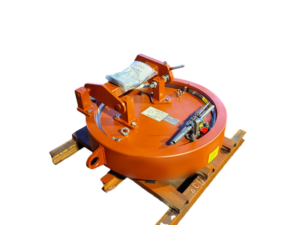

The Lock Ring Pressure Vessel Closure is generally composed of a cylinder, flange, hook or clamp, sub, safety chain mechanism, opening and closing mechanism, swivel arm, and other components. To fix common issues like not being able to open the closure and leaks in the seal, the sealing structure, working principle, and function of the main parts of the closure are studied. Then, typical failures in the production process are used to figure out what went wrong and how to fix it so that the station and yard can run safely and reliably.

Sealing Principle of Закрытие сосуда под давлением со стопорным кольцом

The sealing ring of the Lock Ring Pressure Vessel Closure is a U-shaped seal. The sealing ring is embedded in the sealing groove, and after closing the blind door, the sealing ring adheres to the sealing surface under certain pressure to achieve initial sealing. Under working conditions, the medium in the tube enters the inner cavity of the sealing ring. Under the action of a high-pressure medium, the sealing ring opens and fits the sealing surface more tightly. The greater the pressure, the better the sealing effect. Because the sealing structure adopts a self-tightening seal, there is no pre-tightening force or pre-tightening moment, so the closure has no additional stress, and the sealing is reliable.

Structure

The lock disc is used for security. When the pressure alarm bolt is not removed, the lock plate cannot be removed, and the handle cannot be rotated. The lock ring expansion device is a crank slider mechanism. The expansion principle of the lock ring is that when the handle is rotated, the guide column connected with the handle moves along the circular groove. Thus, the distance of the lock block is changed, and the perimeter of the lock ring is changed. Finally, the expansion of the lock ring in the lock ring slot is realized. When you turn the handle clockwise, the lock block pulls closer and rests in the lock ring slot to secure the closure door. Turn the handle counterclockwise, lock block away, lock ring out of the lock ring slot, and release the closure door

Safety Device

The safety lock plate is used to fix the ring lock’s working position. That is, when the ring lock is attached to the inclined surface of the simplified ring groove, the safety lock plate is inserted between the two lever arms to prevent the risk of radial displacement of the ring lock. A pressure alarm bolt is installed on the safety lock plate. To remove the safety lock plate, remove the pressure alarm bolt first. When loosening the bolt, as long as there is residual pressure in the equipment equipped with the ring-lock type quick-opening blind plate, the gas will be released through the special release port of the pressure alarm bolt. It then makes a sound to warn the operator. This avoids hazards caused by residual pressure when opening the end closure.

Opening and Closing of Закрытие сосуда под давлением со стопорным кольцом

Opening

Before opening the Lock Ring Pressure Vessel Closure, ensure that all pressure in the container is released. Then make it free from the bolt hole and remove the lock block. Insert one end of the universal handle into the hole of the lock ring drive arm. Turn the handle counterclockwise to retract the lock ring into the lock ring groove. Pull the door lever outward horizontally to open the Lock Ring Pressure Vessel Closure.

Closing

When closed, insert one end of the handle into the hole of the lock ring drive arm and turn the handle clockwise to extend the lock ring into the groove of the lock ring. Then push the lever inward to close the door. This allows the door to fully enter the neck of the Lock Ring Pressure Vessel Closure. Then loosen the lock ring so that it is just stuck in the lock ring groove. Pull the lever back and forth a few more times to confirm that it is completely stuck in the groove. Install the lock block, tighten the pressure alarm bolt, and complete the closing operation.

Lock Ring Pressure Vessel Closure Associated Devices

The filter intercepts solid impurities in the conveying medium through a stainless steel screen frame assembly. Special equipment is needed to ensure the normal operation of instruments and important equipment. The filter consists of an air outlet, an inlet, a sewage outlet, an outlet, a blind plate, a filter cartridge, a filter element, etc.

Maintenance cycle

Every time a closure is opened, it needs to be inspected, serviced, and maintained. closure without switching operation should be maintained at most once every six months.

Закрытие сосуда под давлением со стопорным кольцом Security Issues

The safety Lock Ring Pressure Vessel Closure significantly enhances its safety performance. It prevents the radial movement of the lock ring. This reduces the chance of blinds with pressure switches. However, in the case that the pressure relief groove of the pressure alarm bolt is blocked or the relief port is blocked, this method cannot completely guarantee that the pressure in the container is zero. Therefore, the pressure alarm bolt is completely removed to ensure that the pressure is zero. To prevent the combustion and explosion of ferrous sulfide in the container, water should be sprayed into the container to absorb and dissolve ferrous sulfide before fully opening the door.

Отзывов пока нет.