Введение в неинтрузивный сигнализатор для скребков

Обзор неинтрузивных сигнализаторов для скребков при обслуживании трубопроводов

Целостность трубопровода имеет решающее значение, и неинтрузивные сигнализаторы скребков играют ключевую роль в ее поддержании. Эти устройства позволяют операторам обнаруживать, определять местоположение и управлять инструментами очистки и проверки трубопроводов, известными как «скребки», без необходимости прерывать работу трубопровода. Их способность работать без открытия трубопровода или прерывания потока экономит время и снижает риски, что делает их лучшим выбором для эффективного управления трубопроводами.

Важность неинтрузивных методов в нефтегазовой отрасли

В нефтегазовой отрасли минимизация времени простоя имеет решающее значение. Неинтрузивные методы, такие как использование сигнализаторов для скребков, обеспечивают непрерывную работу при соблюдении высоких стандартов безопасности. Они не только предотвращают дорогостоящие простои, но и защищают окружающую среду, снижая риск утечек во время технического обслуживания. По мере роста нормативных требований и усиления внимания к воздействию на окружающую среду внедрение неинтрузивных технологий становится не просто удобством, а необходимостью.

Понимание неинтрузивного сигнализатора для скребков

Что такое сигнализатор для свиней?

Сигнализатор скребка — это устройство, которое обнаруживает присутствие скребка (манометра для осмотра трубопровода) при его движении по трубопроводу. Эти устройства предупреждают операторов, когда свинья проходит определенную точку, помогая следить за ее продвижением и подтверждать ее местоположение. Это необходимо для эффективной очистки, технического обслуживания и осмотра трубопроводов.

Основные функции

К основным функциям сигнализаторов скребков относится сигнализация о прибытии и выходе скребков в назначенных точках трубопровода. Они гарантируют, что скребок не застрянет или не потеряется, что имеет решающее значение для поддержания целостности трубопровода и эксплуатационной эффективности. Кроме того, они предоставляют ценные данные, которые могут помочь в планировании технического обслуживания и минимизации времени простоя.

Типы сигнализаторов для скребков

Сигнализаторы для скребков бывают разных типов, но наиболее распространенное различие заключается в том, что модели являются интрузивными и неинтрузивными.

Сравнение интрузивного и неинтрузивного сигнализатора для скребков

Интрузивные сигнализаторы скребка физически проникают через стенку трубопровода и могут напрямую контактировать со скребком. Этот метод очень надежен, но требует прорыва в трубопроводе, что может привести к потенциальным утечкам или слабым местам.

С другой стороны, неинтрузивные сигнализаторы скребков работают снаружи трубопровода. Они используют магнитные, акустические или вибрационные датчики для обнаружения прохода свиньи. Этот метод не ставит под угрозу целостность трубопровода, предлагая более безопасный и экологичный вариант, особенно подходящий для сред с высоким давлением или когда содержимое трубопровода должно оставаться незагрязненным.

Таким образом, выбор между этими типами зависит от конкретных условий трубопровода, эксплуатационных требований и соображений безопасности. Неинтрузивные сигнализаторы для скребков, обладающие преимуществами в области безопасности и эффективности, становятся все более предпочтительным выбором во многих сценариях.

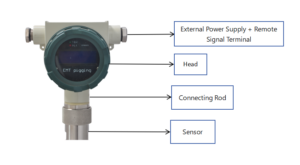

Спецификации

| Имя | Неинтрузивный сигнализатор для скребков |

| Рабочая температура | —39,8°C/80°C |

| Влажность при эксплуатации | 41%~83% |

| Тип датчика | Магнитная индукция |

| Тип сигнального переключателя | СПДТ |

| Скоротаченное время | ±2 сек. |

| Диапазон скоростей очистки скребка | 0.2-10 м/с |

| Емкость коммутатора | 2А |

| Тип сброса | Авто управление |

| Тип кабельного соединения | M20 * 1,5 、 1/2NPT F |

| Взрывозащищенность | Exd IICT6 Гб |

| Класс IP | IP65 |

Промышленное применение

Нефтегазовая отрасль

В нефтегазовом секторе трубопроводы являются спасательными кругами, по которым транспортируются ценные ресурсы. Неинтрузивные сигнализаторы скребков помогают обслуживать эти трубопроводы, гарантируя, что скребки, которые чистят и проверяют трубопроводы, успешно завершают свои маршруты. Операторы используют эти сигнализаторы для предотвращения засоров и контроля износа внутри трубопровода. Такое упреждающее техническое обслуживание помогает избежать дорогостоящего ремонта и простоев, повышая эффективность работы.

Водоподготовка

В системах водоподготовки поддержание целостности трубопровода не менее важно. Неинтрузивные сигнализаторы для скребков хорошо адаптируются к этим условиям, помогая бороться с отложениями и остатками, которые могут накапливаться в водотранспортных линиях. Они обеспечивают безопасный и эффективный метод мониторинга процессов очистки без загрязнения системы водоснабжения, обеспечивая соблюдение стандартов охраны труда и техники безопасности.

Часто задаваемые вопросы

- Каков срок службы неинтрузивного сигнализатора для скребков?

Как правило, неинтрузивный сигнализатор скребка может прослужить от 5 до 10 лет, в зависимости от частоты использования и условий окружающей среды. - Как погода влияет на работу неинтрузивных сигнализаторов для скребков?

Экстремальные температуры и влажность могут повлиять на работу датчика. Тем не менее, большинство современных агрегатов спроектированы так, чтобы выдерживать суровые погодные условия. - Можно ли использовать неинтрузивные сигнализаторы скребков во всех типах трубопроводов?

Да, они универсальны и могут использоваться в различных трубопроводах, включая нефть, газ и воду, независимо от содержимого трубопровода. - Каковы первоначальные затраты на установку неинтрузивного сигнализатора для скребков?

Стоимость варьируется в зависимости от размера трубопровода и конкретных требований, но обычно включает в себя цену установки и плату за установку. - Как интерпретировать сигналы от неинтрузивного сигнализатора от скребка?

Каждый сигнал указывает на присутствие свиньи в определенной точке. Операторы должны понимать эти сигналы, чтобы отслеживать движение скребка и обеспечивать эффективное техническое обслуживание трубопровода.

В этих разделах представлена важная информация о практическом применении неинтрузивных сигнализаторов для скребков в критически важных отраслях промышленности и ответы на распространенные вопросы, которые могут помочь пользователям принимать обоснованные решения о стратегиях управления трубопроводами.

Отзывов пока нет.