Установка

The initial installation of the Pig Barrel Closure should strictly abide by the following rules:

PWHT (Post Weld Heat Treatment) Recommendation for Pig Barrel Closure

Local Heating

When doing PWHT on the circumferential weld, it’s better to do local heat treatment.

If the technical requirements of the equipment’s general manufacturing drawing stipulate that the whole Post Weld Heat Treatment is a must, you must use rock wool, aluminum silicate, or other thermal insulation materials to protect the sealing surface from oxidation.

PWHT should strictly abide by GB150.4 Section 8.2, or the ASME standard. Or it should abide by the mature heat treatment of the PWHT factory.

Caution:

1) Before PWHT, dismount the headcover. After PWHT, reset the headcover.

2) Before PWHT, if you do not dismount the head cover, make sure to remove all the seals.

3) After PWHT, you should slightly wipe clean the sealing surface with a fine emery cloth. Then evenly apply grease, glycerin, or anti-rust oil.

Attention: During heat treatment, put nothing on the closure!

Painting

Before painting the Pig Barrel Closure, you must remove the safety interlock. All the components that do not need painting should be wrapped. For example, seal surfaces, internal and external threads, fasteners, welding grooves, stainless steel parts, copper parts, and electroplated parts. This can avoid impacting assembly accuracy, usability, and beauty and prevent blasting and painting from entering.

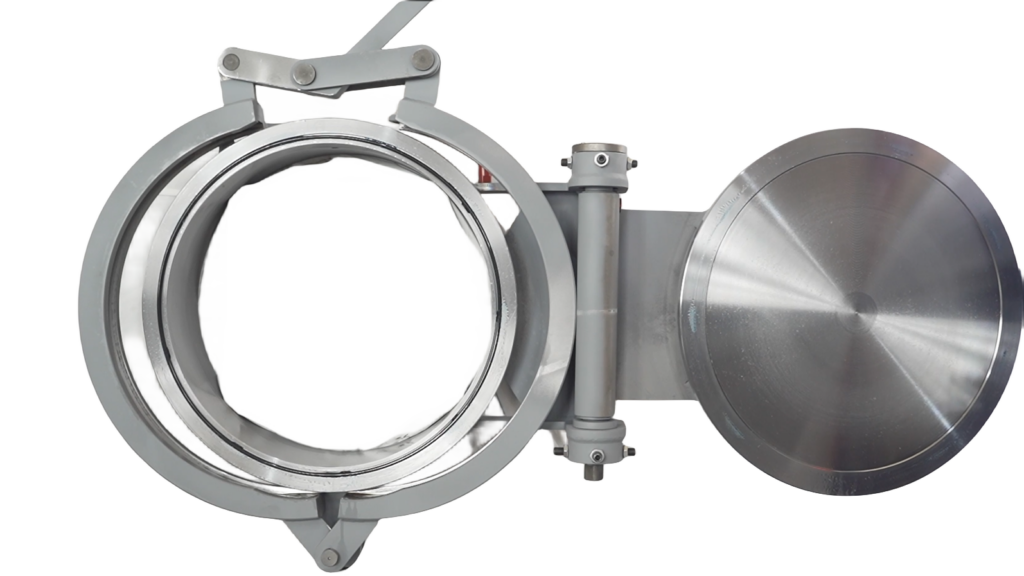

The re-installation of the Pig Barrel Closure Cover

When re-installing the head cover, please do as follows:

1. First, you should conduct corrosion prevention on all seal surfaces. For the specific operation, please see the maintenance part.

2. Remove the seal, and with the cooperation of the crane, the sealing surface of the head cover is closed with the sealing surface of the cylinder flange.

(Pay attention: During the assembly procedure, it will produce the amount of tolerance and the self-supporting effect. After the assembly, and when opening the Pig Barrel Closure, the head cover will make a downward vertical displacement.)

3. Assemble the adjusting shaft. Tighten the eight adjustment bolts at the upper and lower ends of the adjustment shaft.

Special Warning: When tightening the adjustment bolt, absolutely avoid any movement of the adjustment shaft in any direction!

4. Install the upper-end cover of the adjusting shaft

5. Install the upper end cover of the adjustment shaft for 2 to 3 times of opening and closing test, and adjust the head cover by fine-tuning the lower square of the adjustment shaft

Содержание

Protection and anti-corrosion

No matter how long the Pig Barrel Closure has been stored, you must make a thorough inspection and maintenance.

The procedure is as follows:

1) First you should do a complete inspection of all the components:

2) Take out the seals. Then thoroughly clean the sealing surface, seal groove, and various parts. Each detail should be clean.

3) Evenly apply a layer of anti-rust grease (grease, Vaseline, glycerin can be used) in the sealing surface and sealing tank, and lubricate all rotating parts with oil.

4) Reloading the sealing ring into the sealing slot should be performed in the order of first installing 12 and 6 o ‘clock directions and holding them down, and then installing 3 and 9 o ‘clock directions.

5) Close the head cover.

6) Wrap the quick-opening blind plate with a plastic sheet and put it into a packing box. Put the packing box into a suitable place in the warehouse for storage.

7) Stored quick-opening blinds should be inspected and maintained at least once a year

Seal Replacement

1. If you need to replace the sealing ring, use a tool with a smooth head and no sharp edges to remove the sealing ring from the sealing slot. Be careful not to damage the sealing surface of the sealing slot.

2. After removing the sealing ring, wipe the sealing groove and sealing surface thoroughly; do not allow water stains, rust, oil dirt, dirt, or other debris; and then evenly apply a layer of grease (grease, vaseline, or glycerin can be used).

3. Put the sealing ring into the sealing slot, install the 12 and 6 o ‘clock directions first, and then install the 3 and 9 o ‘clock directions.

Special tips: Keep the sealing groove and sealing surface lubricated, which is conducive to sealing, sealing ring replacement, preventing rust, and easy to operate.

Routine Maintenance

To ensure that the Pig Barrel Closure is always in good working condition, please perform the following routine maintenance regularly

Pay Attention:

It is very dangerous to neglect daily maintenance and routine inspections and not pay attention to the protection of the seal.

Any defect in the sealing groove, sealing ring, or sealing surface will lead to leakage and cause accidents.

Barrel and Head Cover

a) Thoroughly clean the sealing parts of the head cover and cylinder flange, and check whether there is mechanical damage to each sealing surface.

b) Evenly apply a layer of grease (grease, Vaseline, glycerin) to the sealing tank and sealing surface;

c) Close the head cover and check whether the head cover is centered. If it is not centered, adjust the lower four sides of the shaft with a wrench. If necessary, adjust the 8 bolts above and below the adjusting shaft to cooperate.

Отзывов пока нет.