ąŚąĮą░ą║ąŠą╝čüčéą▓ąŠ

Pigging is important in pipeline construction and operation. It is significant for ensuring pipeline safety and reducing pipeline energy consumption. The main problem of domestic pipe pigging is that the effect is not ideal, especially for the pipe with large drops. Pig tracking and forecasting accuracy are low, and some problems such as pigging occur. EMT provides a variety of pigging tools for pipeline systems.

Working Principles of Pigging Tools

In the pipeline to be operated, the corresponding series of pigs is placed according to the requirements of the operation. The outer edge of the pig cup is elastomically sealed with the inner wall of the pipeline, and the pressure difference generated by the pipe transport medium is used as the driving force to push the pig along the pipeline. The scaling or sediment in the pipeline is removed by the scraping and scouring function of the pig itself or the machine it carries.

Functions of Pigging Tools

1. Natural gas pipeline in operation:

Pigging tools can remove water, light oil, methane hydrate, iron oxide, carbide dust, carbon disulfide, hydrosulfuric acid and other corrosive substances inside the pipeline. Reduce the corrosion damage of corrosive substances to the inner wall of the pipeline. Re-define the pipeline direction. Detect pipeline deformation. Check the integrity rate of valves along the line. Reduce working back pressure.

2. Operation of China Crude oil pipeline:

Pigging before inspection in the pipeline and intermittent operation of pipeline pigging at low throughput. Remove condensate, wax, and scale inside the pipeline. Thus, the purpose of reducing the oil back pressure, reducing the wear resistance, and reducing the oil temperature is achieved.

3. Chemical materials and edible oil pipelines:

Clean lines of cohesive materials. It can achieve single pipe multi-product transport, and metering pipe transport media by isolating different pipe transport media.

4. Sectional pigging line sweeping pressure test:

Remove pipeline debris, rust, drainage, and exhaust.

5. Total pipe pigging pressure test:

Detect pipeline deformation and construction quality. Exhaust before hydraulic test, drain before production, dry, medium isolation.

6. Water transmission and injection pipeline:

Remove scale and sediment.

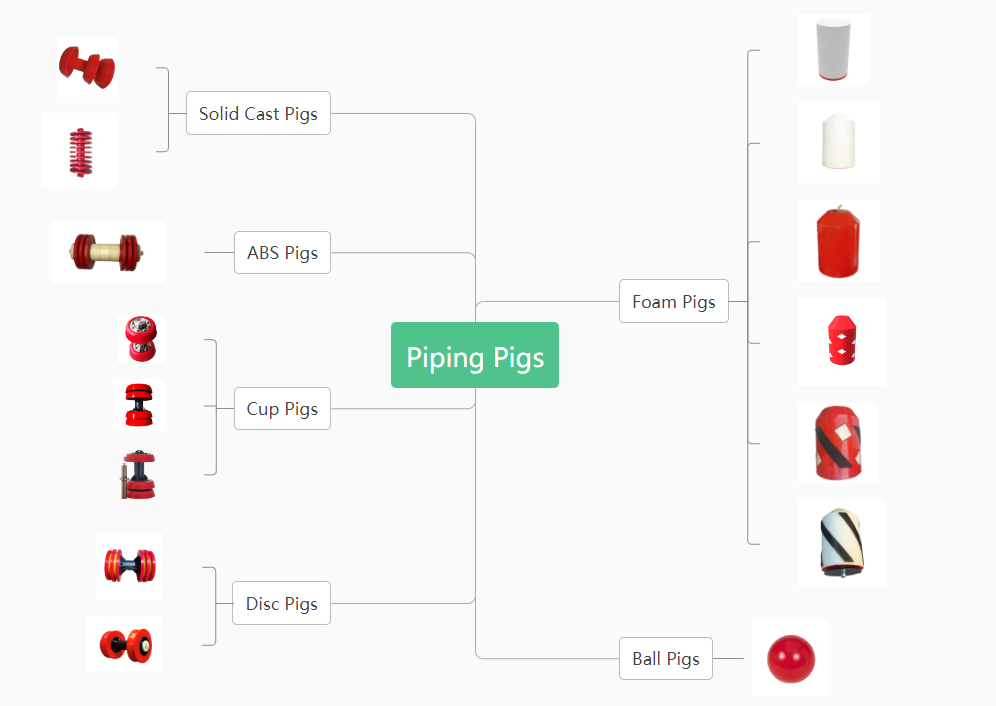

Types of Pigging Tools

There are many kinds of pigging tools. Take pipeline-cleaning pigs as an example. There are mechanical cleaning pigs, foam pigs, sphere pigs, ABS pigs, solid cast pigs, and fluoro rubber pigs.

ą£ąĄčģą░ąĮąĖč湥čüą║ąĖąĄ ąŠčćąĖčüčéąĮčŗąĄ čüą║čĆąĄą▒ą║ąĖ

Mechanical cleaning pigs mainly have two kinds: pigs with cups and pigs with discs.

Pigs with cups stand out for their exceptional sealing and adaptability. These pigs excel in sealing, making them perfect for separating fluids or purging lines during maintenance. Their flexible cups adjust to variations in pipeline diameter, enabling smooth navigation through bends and offsets. This adaptability ensures they maintain contact with pipe walls, effectively removing debris and liquids. Cup pigs also minimize product contamination, which is crucial for maintaining product purity during batch operations.

On the other hand, pigs with discs offer superior cleaning strength and durability. Disc pigs boast a sturdy design, managing high-pressure differentials without damage, making them ideal for long pipeline runs. Their scraping action is aggressive, removing tough deposits and ensuring a thorough clean. The resilience of disc materials means less wear over time, providing cost savings on replacements. These pigs also maintain a consistent speed, which helps in effective cleaning and avoiding pipeline blockages.

Foam Pigs

Foam pigs are a versatile and lightweight pipeline cleaning solution. Made from flexible foam, they can compress and expand to fit various pipeline diameters, making them perfect for multi-diameter pipe systems. They are excellent for wiping and drying lines, removing debris, and performing general maintenance. Their cost-effectiveness and adaptability for different applications make them a popular choice among pipeline operators. Foam pigs can also be coated with abrasives to tackle tougher cleaning jobs, adding to their utility.

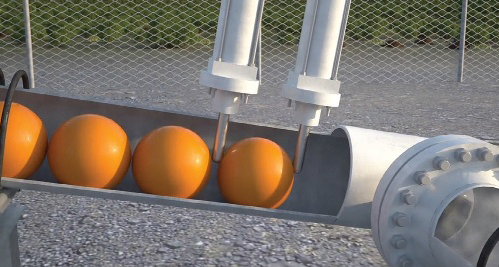

Sphere Pigs

Sphere pigs showcase remarkable flexibility, allowing them to traverse pipeline irregularities with ease. Their spherical shape enables them to maneuver through tight bends and multi-diameter pipes that other pigs cannot. This versatility makes them ideal for varied pipeline topographies. Additionally, sphere pigs require less driving force, reducing operational costs and strain on pumping equipment. Their design also allows for effective separation of different fluids within the pipeline, and they can serve as a good indicator of pipeline conditions based on the wear they exhibit after a run.

Moreover, the simplicity of sphere pigs means they have fewer parts that could potentially fail, leading to a lower likelihood of getting stuck or causing damage to the pipeline. They are also lightweight and easy to handle, making them a convenient choice for operators. The ability to easily insert and remove them from pig launchers and receivers enhances operational efficiency. Furthermore, their construction from materials like foam or solid polyurethane makes them a cost-effective option for routine pigging operations.

ąŚą░ą║ą╗čÄč湥ąĮąĖąĄ

To conclude, pigging tools are indispensable for robust pipeline maintenance and operation. Mechanical, foam, and sphere pigs each tackle specific challenges effectively. They ensure safety, enhance performance, and cut energy costs. Innovations in pigging technology will further improve the precision and efficiency of these essential tools. As a result, pipelines will continue to operate smoothly, safely, and economically well into the future.

ą×čéąĘčŗą▓ąŠą▓ ą┐ąŠą║ą░ ąĮąĄčé.