I. Введение

Overview of Pipeline Engineering Pig Signaller

At Pipeline Engineering, we actively enhance the safety and efficiency of pipeline systems worldwide. Our commitment stems from a tradition of engineering excellence, driving us to continuously innovate and improve our technologies to address the evolving needs of the industry. By focusing on reliable and advanced solutions, we strive to set new standards in pipeline safety and operational efficiency.

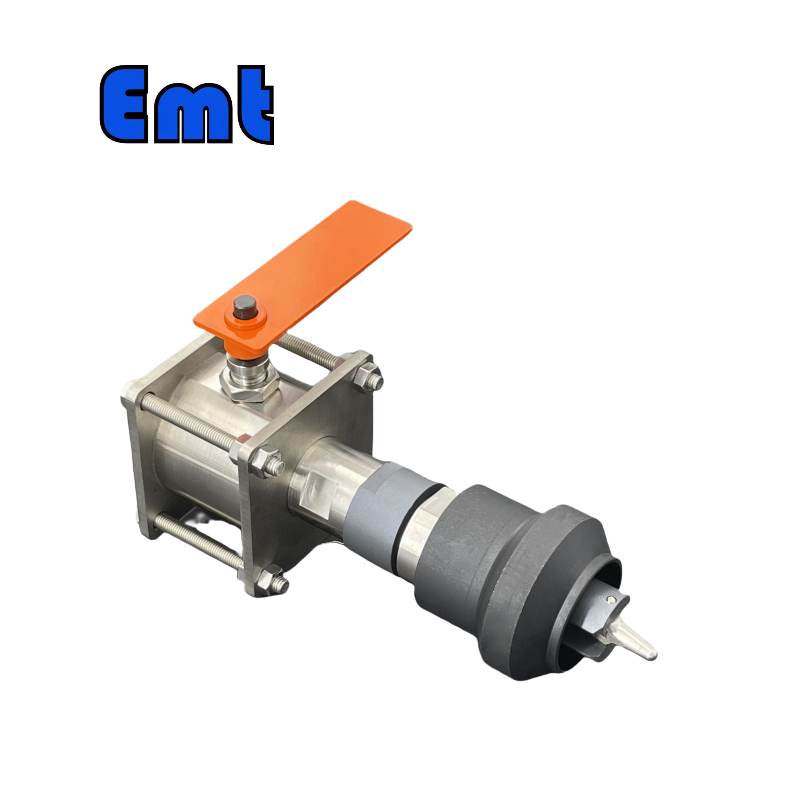

Introduction to the Pig Signaller

The Pig Signaller is a paramount device in our suite of pipeline maintenance tools. Designed to ensure the smooth operation of pipeline inspection and cleaning processes, this device plays a critical role in the detection, signaling, and registration of the passage of pigs—tools used for cleaning and inspecting pipelines—as they travel through the pipeline system.

II. Role and Importance of the Pig Signaller

Functional Explanation of Pig Signallers

The primary function of a Pig Signaller is to detect the presence of a pig as it moves through a pipeline, signal its passage, and register this event. This capability is crucial for the real-time monitoring of pigging operations, which are essential for the maintenance and integrity of pipeline systems.

Discussion on the Significance in Pipeline Maintenance

Pig Signallers are integral to maintaining the integrity and efficiency of pipeline systems. They provide operators with vital information that helps prevent potential pipeline blockages and ensures that all maintenance pigs have passed through the designated sections of the pipeline successfully. This not only helps in preemptive maintenance planning but also enhances the overall safety and longevity of pipeline infrastructure.

III. Features and Specifications of the Pig Signaller

Overview of Key Features

Our Pig Signallers feature a design that prioritizes versatility and adaptability. Key elements include a removable structure that enables easy maintenance and replacement without interrupting operations. We offer a range of trigger types—bi-directional, bi-directional feather, and uni-directional—that allow for customization to specific pipeline activities, ensuring precise detection across diverse operational scenarios.

Advanced Indicator Features

The advanced indicator features of our Pig Signallers set them apart. These include manual reset flags for straightforward operations and combinations of manual reset flags with electrical signals for enhanced monitoring capabilities. Some models also incorporate date and time displays linked with electrical signals, providing detailed tracking and data logging of pigging operations.

Detailed Description of Design Aspects

- Double Block and Bleed (DBB) Valve: The integration of a DBB valve in our Pig Signallers enhances operational safety by allowing the device to be isolated and safely removed under pressure, reducing system downtime and increasing operational flexibility.

- Explosion-Proof Classification: Adhering to the highest safety standards, our Pig Signallers come with an ExdⅡ BT4 explosion-proof classification, making them suitable for use in volatile environments where safety is paramount.

- Ingress Protection: With IP65/IP66 certification, our Pig Signallers are protected against dust and high-pressure water jets, ensuring durability and reliability even in harsh environmental conditions.

Highlighting Customization Options

To meet the diverse needs of our clients, we offer extensive customization options for our Pig Signallers:

- Material Selection: Clients can choose from materials like 316L stainless steel, duplex stainless steel, and Inconel, depending on their specific environmental and chemical compatibility needs.

- Operational Adaptability: The trigger mechanism’s flexibility can be tailored and verified online to suit specific operational requirements, ensuring optimal performance.

- Configurable Specifications: Our Pig Signallers are designed to perform across a wide range of operational temperatures and pressures, making them versatile tools capable of adapting to various industrial applications.

In conclusion, the Pig Signaller from Pipeline Engineering is not just a tool but a comprehensive solution designed to enhance the safety, efficiency, and reliability of pipeline operations. With its advanced features and customizable options, it stands as a testament to our commitment to leading the industry in innovation and quality.

IV. Types of Pig Signallers Offered

Description of Mechanical Signallers:

Mechanical signallers are a cornerstone of traditional pipeline maintenance. They operate through direct physical contact with the pig, utilizing a mechanical trigger mechanism. This design is particularly suited to environments where durability and mechanical simplicity are paramount.

Advantages of Using Mechanical Signallers:

Mechanical signallers shine in straightforward, less complex pipeline systems where robustness and reliability are key. Their simplicity ensures fewer malfunctions and easy maintenance, making them ideal for operations where electronic systems might be prone to interference or where simplicity is preferred for quick visual confirmation of pig passage.

Description of Non-Intrusive Signallers:

Moving to advanced pipeline monitoring, our non-intrusive signallers employ either magnetic or ultrasonic technologies to detect the passage of pigs. These devices do not require direct contact with the pig, thus avoiding any potential disruption to the pig or the internal surface of the pipeline.

Technology Used and Advantages:

Magnetic Signallers: These devices monitor changes in the magnetic field generated by a pig as it moves through a pipeline. They are particularly effective in settings where the installation of mechanical parts is impractical or undesirable.

Ultrasonic Signallers: These devices use sound waves to detect the presence of a pig, capturing shifts in sound patterns within the pipeline. They are invaluable in high-speed or multi-product pipelines, where accuracy and precision in detection are critical.

Ideal Scenarios for the Use of Non-Intrusive Signallers:

Non-intrusive signallers shine in high-pressure environments, pipelines that carry sensitive or corrosive materials, or in situations where maintaining pipeline integrity is critical. They significantly lower the risk of leaks or damage that could occur from installing mechanical signallers, ensuring the pipeline’s structural integrity remains intact.

V. Selection Criteria for Pig Signallers

Selecting the right Pig Signaller requires careful consideration of various factors to ensure it matches your pipeline’s needs and enhances operational performance:

Pipeline Type

- Physical Characteristics: Evaluate the diameter, material, and construction of your pipeline. These characteristics dictate the type of Pig Signaller suitable for your system.

Nature of Pigging Operation

- Purpose of Pigging: Determine the pigging operation—cleaning, inspection, or separation. This decision will guide the technology and features required in the Pig Signaller.

Operational Environment

- Environmental Conditions: Consider the presence of volatile materials, extreme temperatures, and pressure levels. These elements are crucial for choosing a signaller that can perform reliably under your specific environmental conditions.

How Pipeline Engineering Assists Customers

At Pipeline Engineering, we actively engage with you to ensure you choose the perfect Pig Signaller:

- Personalized Consultation: We start by analyzing the specifications and operational needs of your pipeline. This thorough understanding allows us to address your unique challenges effectively.

- Expert Recommendations: Our specialists then recommend Pig Signallers that are specifically tailored to your requirements. These recommendations focus on enhancing the reliability and effectiveness of your pigging operations.

- Ensured Effectiveness: Our goal is to optimize your operations. By providing perfectly matched Pig Signallers, we help you maintain efficient and reliable pipeline systems.

VI. Commitment to Customer Service and Support

Our commitment to service excellence is demonstrated through:

Diverse Product Range: We offer a wide array of Pig Signallers to meet different technical and environmental requirements.

Quality Assurance: Every Pig Signaller we produce is rigorously tested to meet the highest standards of quality and reliability.

Responsive Customer Service: Our team provides swift and informative responses to all inquiries, ensuring that you have all the information needed to make informed decisions.

Efficient Delivery: We pride ourselves on our ability to quickly fulfill orders, minimizing downtime and enhancing your operational continuity.

Continuous Support: Our support extends beyond purchase, with comprehensive after-sales service to assist with any operational challenges.

VII. Заключение

In conclusion, Pipeline Engineering Pig Signaller plays an indispensable role in modern pigging operations. These essential tools significantly enhance the safety, efficiency, and reliability of pipeline systems. If you aim to improve your pipeline maintenance strategies, Pipeline Engineering provides innovative solutions and expert guidance. Contact us to learn how our Pig Signallers can revolutionize your operations and to explore the benefits of integrating these vital tools into your maintenance protocols.

Отзывов пока нет.